Diaphragm type pulsation damper with high pressure resistance

A pulsation damper, diaphragm type technology, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of unusable, unsatisfactory high-pressure working conditions, etc., to slow down the deformation trend, improve the service life, The effect of improving the ability to withstand high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

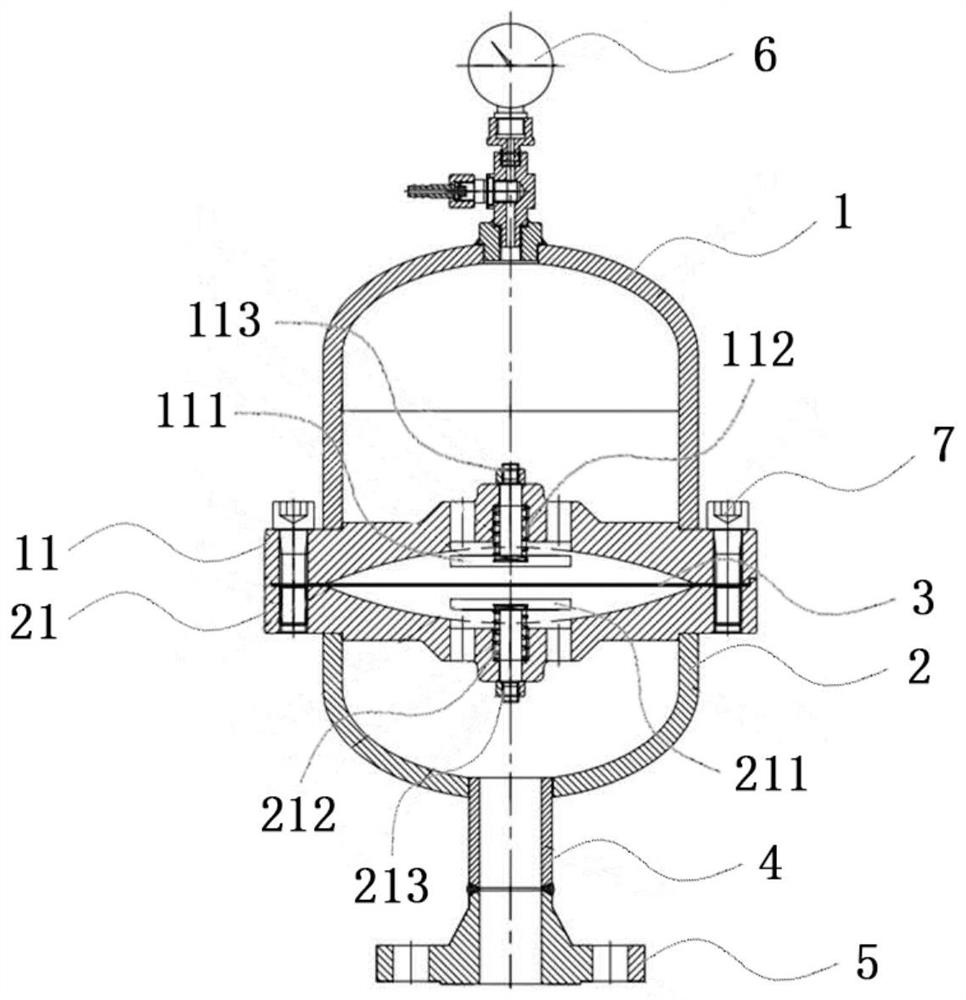

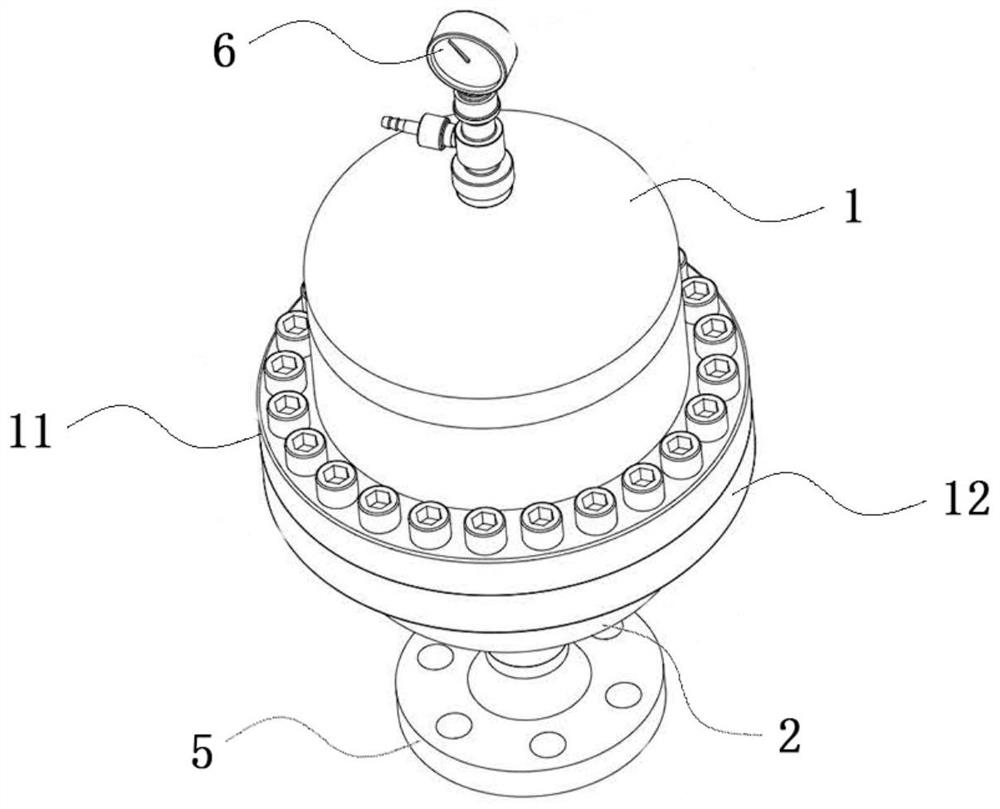

[0026] like figure 1 and figure 2 As shown, this embodiment shows a diaphragm-type pulsation damper with high pressure resistance, including a first casing 1 and a second casing 2. The first casing 1 is provided with a first chamber, so The second housing 2 is provided with a second chamber, and a diaphragm 3 is provided between the first housing 1 and the second housing 2 for isolating the first chamber and the second chamber. A housing 1 is provided with an inflatable component 6 that communicates with the first chamber, the bottom of the second housing 2 is provided with a connecting pipe 4, and the first housing 1 is provided with a first limiting block 11. The first limiting block 11 is provided with a first through hole for communicating with the first chamber, the first limiting block 11 is provided with a first protective film device, and the first limiting block 11 is connected to the first protective film. A first return spring 112 is arranged between the membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com