A moving beam locking device for a gantry five-axis machine

A technology of locking device and five-axis machine, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of large gravity and turning moment, vibration of moving beam processing, easy to produce deformation, etc., to improve precision , improve processing efficiency, reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

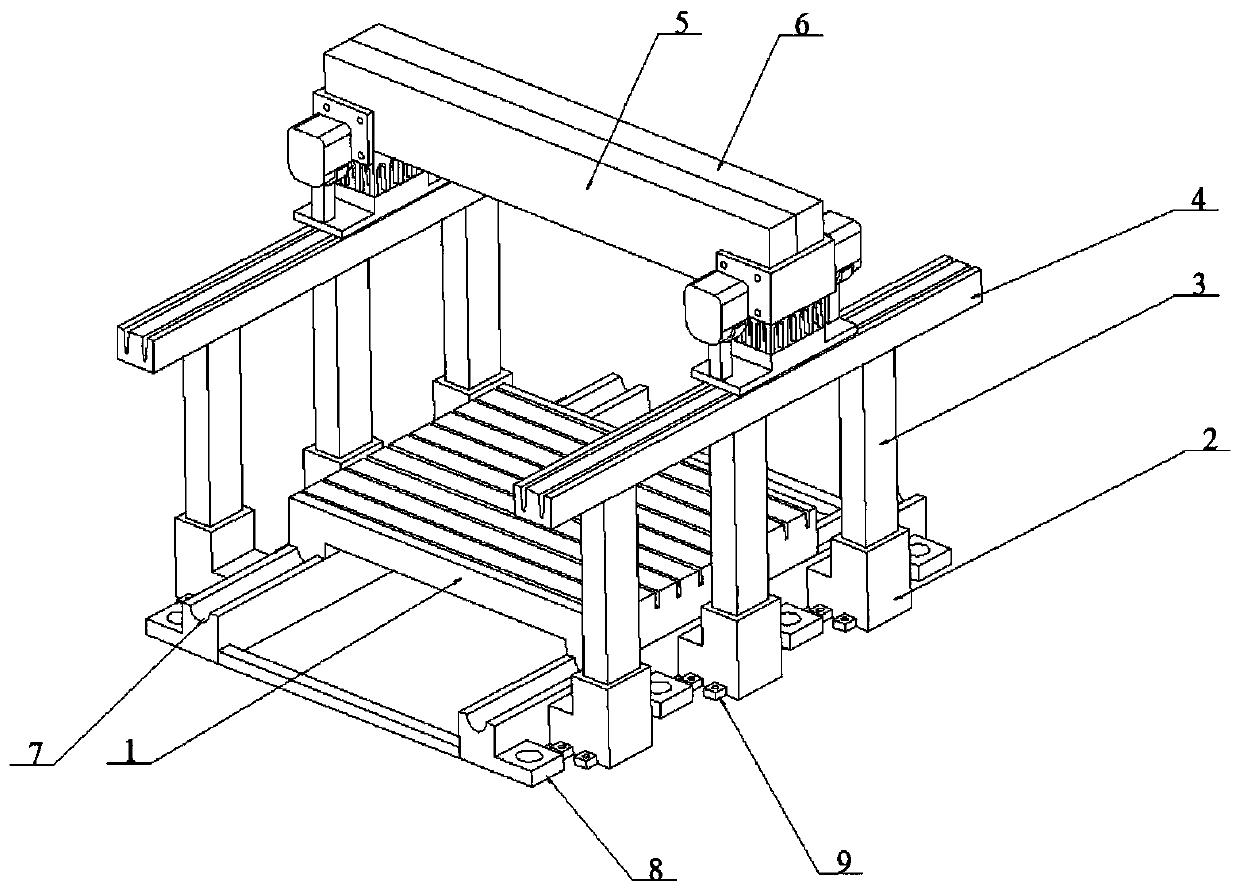

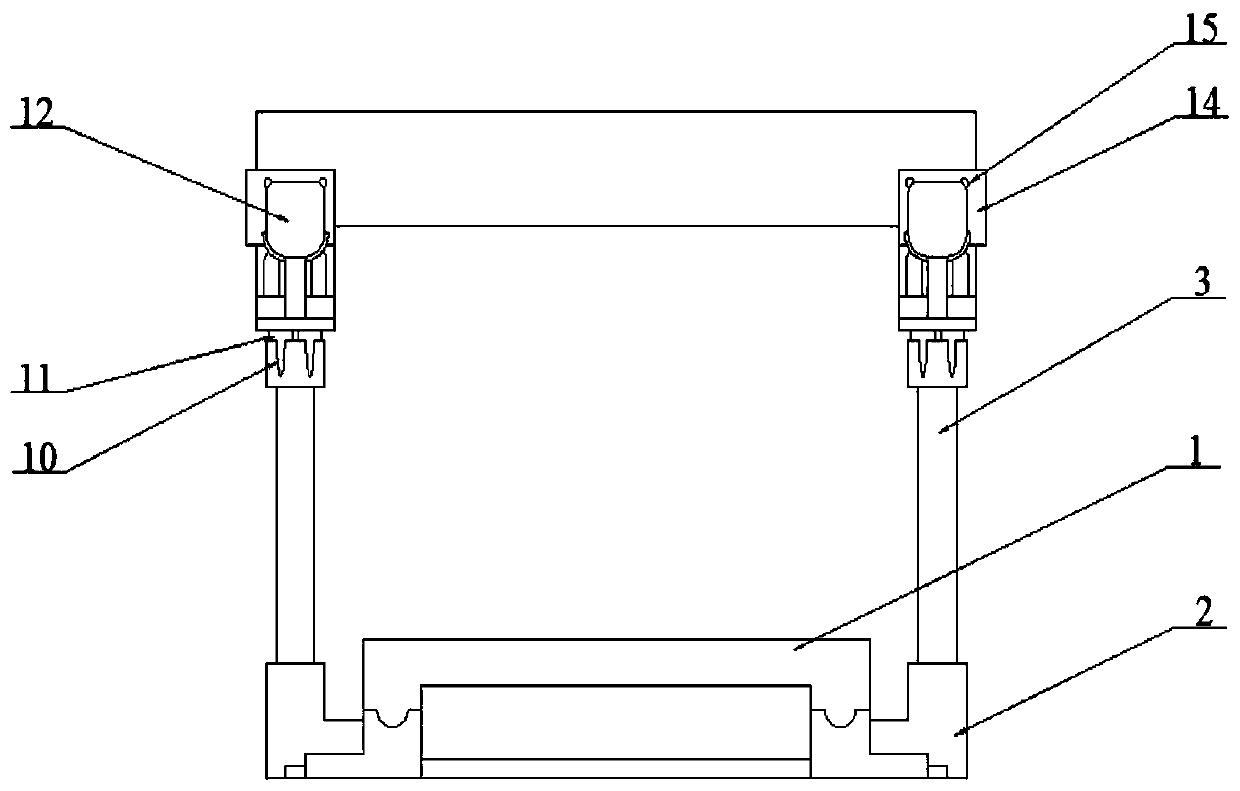

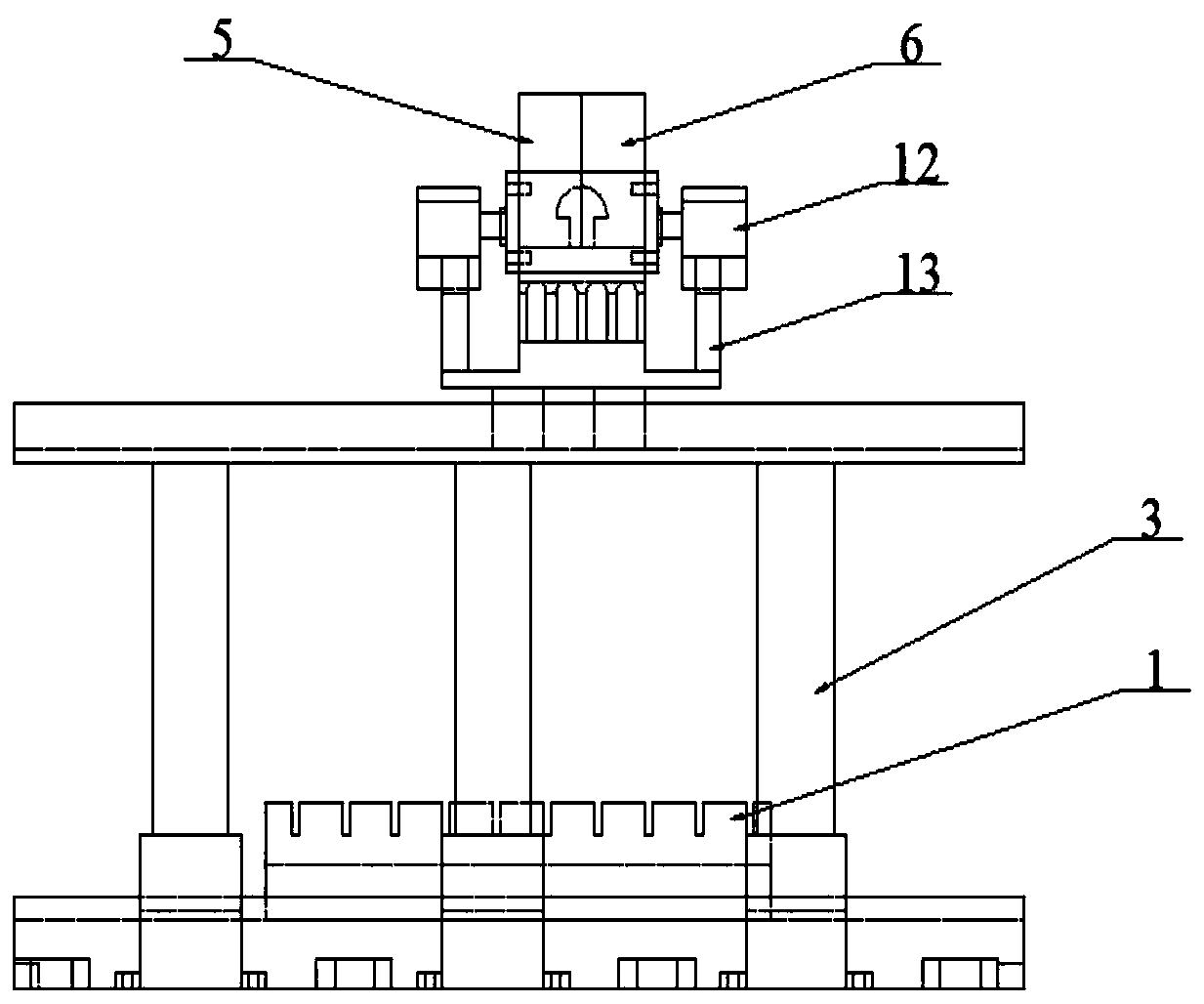

[0036] see Figure 1-9 , a moving beam locking device for a gantry five-axis machine of the present invention, including a workbench 1, a base 2, a column 3, a second guide rail 4, a beam I5, a beam II 6, a first guide rail 7, a big foot iron 8, and a small foot Iron 9, chute 10, slider 11, hydraulic cylinder 12, bracket 13, locking plate 14, bolt hole Ⅰ15, support seat 16, connecting block 17, arched gate post 18, bolt hole Ⅱ19, anchor connection structure 20 , Piston rod 21, inner groove 22, bolt hole III 23.

[0037] The workbench 1 slides on the first guide rails 7, two first guide rails 7 sides are provided with some big feet 8, the first guide rails 7 are fixed on the ground by the big feet 8, and each first guide rail side 7 is set A number of bases 2, the sides of the base 2 are respectively provided with two small foot irons 9, the base 2 is fixed on the ground by the small foot irons 9, the upper end of each base 2 is correspondingly provided with a column 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com