Production device and production process for preserved and spicy mustard

A production equipment and technology for preparing spicy dishes, which are applied in food preparation, application, food science, etc., can solve problems such as unfavorable industrialization, inability to prepare spicy dishes, and inability to store for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

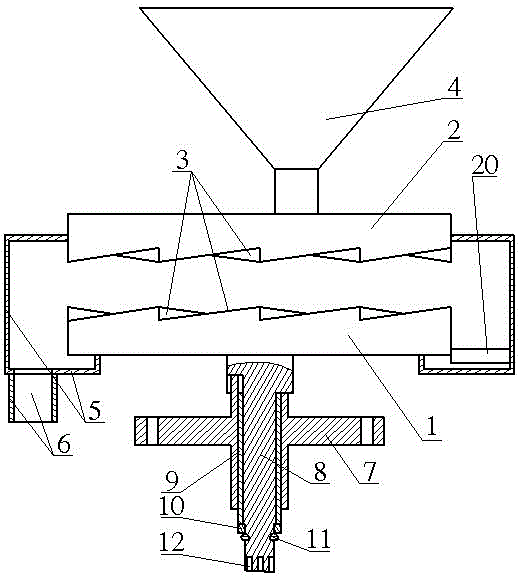

[0077] The production equipment for the spicy vegetable of the present invention mainly includes the production equipment, which mainly includes a kneading machine for the spicy vegetable and a lettuce water squeezer.

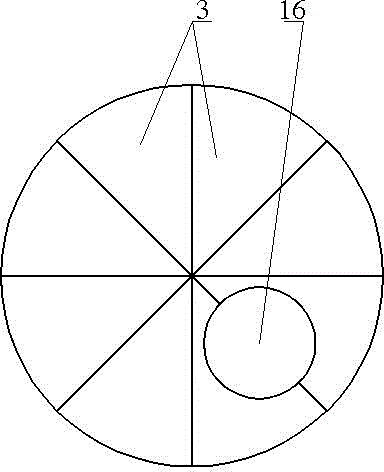

[0078] The kneading machine for hot and spicy vegetables mainly includes a fixed plate 2, a kneading plate 1, a hopper 4, a material storage shell 5, a feeding opening 6, a kneading support 7, a sliding bushing 9, a baffle 10, and a circlip 11. , rotating shaft 8, spline sleeve, transmission, motor;

[0079] The bottom of the kneading plate 1 is fixed with a rotating shaft 8 or is integrated with the rotating shaft 8, the rotating shaft 8 is covered with a sliding bushing 9, and the kneading support 7 is fixed and supports the rotating shaft 8 through the sliding bushing 9, The spline tooth 12 at the lower part of the rotating shaft 8 is connected with the spline sleeve, the spline sleeve is connected with the output shaft of the transmission, and the input sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com