A thermal magnesium smelting process

A process and method of magnesium, applied in the field of thermal magnesium smelting process, can solve the problems of complex operation, waste of equipment investment, labor, etc., and achieve the effect of eliminating calcination system, reducing waste of raw materials and unique process method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

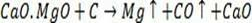

[0025] A thermal magnesium smelting process whose ore raw material is dolomite CaCO 3 .MgCO 3 or magnesite MgCO 3 and limestone CaCO 3 The mixture, the reducing agent is ferrosilicon: the alloy FeSi of silicon and iron, which contains a certain proportion of active silicon, and the catalyst is fluorite CaF 2 .

[0026] First, the ore raw material containing magnesium carbonate, reducing agent, and fluorite catalyst are crushed, mixed according to the reasonable ratio required for the reduction reaction, and ground into a powder with a particle size of no more than 500 mesh, and then the mixed powder is extruded into a converted equivalent by a press Approximate walnut-shaped, pillow-shaped, ellipsoidal, spherical, cylindrical and other solid blocks with a diameter of no more than 100 mm, and the pressed pellets are placed in a closed reactor, and finally heated by the pellets , Exhaust, heat up, and vacuumize to produce magnesium metal.

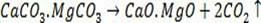

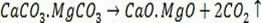

[0027] The chemical reaction in t...

Embodiment 2

[0037] A thermal magnesium smelting process whose ore raw material is dolomite CaCO 3. MgCO 3 , or magnesite MgCO 3 and limestone CaCO 3 mixtures, or magnesite MgCO 3 , the reducing agent is coal, coke, petroleum coke, graphite and other carbon-rich substances, and the catalyst is fluorite CaF 2 .

[0038] First, the ore raw material containing magnesium carbonate, reducing agent, and fluorite catalyst are crushed, mixed according to the reasonable ratio required for the reduction reaction, and ground into a powder with a particle size of no more than 500 mesh, and then the mixed powder is extruded into a converted equivalent by a press Approximate walnut-shaped, pillow-shaped, ellipsoidal, spherical, cylindrical and other solid blocks with a diameter of no more than 100 mm, and the pressed pellets are placed in a closed reactor, and finally heated by the pellets , Exhaust, heat up, and vacuumize to produce magnesium metal.

[0039] When the raw material is dolomite, or ...

Embodiment 3

[0054] A thermal magnesium smelting process whose ore raw material is dolomite CaCO 3 .MgCO 3 , or magnesite MgCO 3 and limestone CaCO 3 mixtures, or magnesite MgCO 3 , the reducing agent is calcium carbide CaC 2 , the catalyst is fluorite CaF 2 .

[0055] First, the ore raw material containing magnesium carbonate, reducing agent, and fluorite catalyst are crushed, mixed according to the reasonable ratio required for the reduction reaction, and ground into a powder with a particle size of no more than 500 mesh, and then the mixed powder is extruded into a converted equivalent by a press Approximate walnut-shaped, pillow-shaped, ellipsoidal, spherical, cylindrical and other solid blocks with a diameter of no more than 100 mm, and the pressed pellets are placed in a closed reactor, and finally heated by the pellets , Exhaust, heat up, and vacuumize to produce magnesium metal.

[0056] When the raw material is dolomite, or magnesite MgCO 3 and limestone CaCO 3 When the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com