Method of casting thick-wall casting through sand insulation cold iron

A technology for sand-separated cold iron and thick-walled castings, which is applied in the field of casting thick-walled castings, can solve the problems of time-consuming and labor-intensive production, high casting production costs, and achieve the effects of reducing production costs, improving cleaning efficiency, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

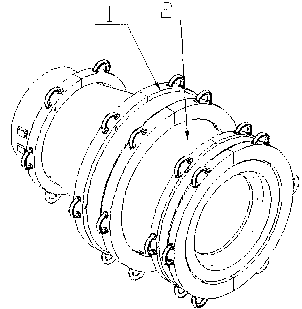

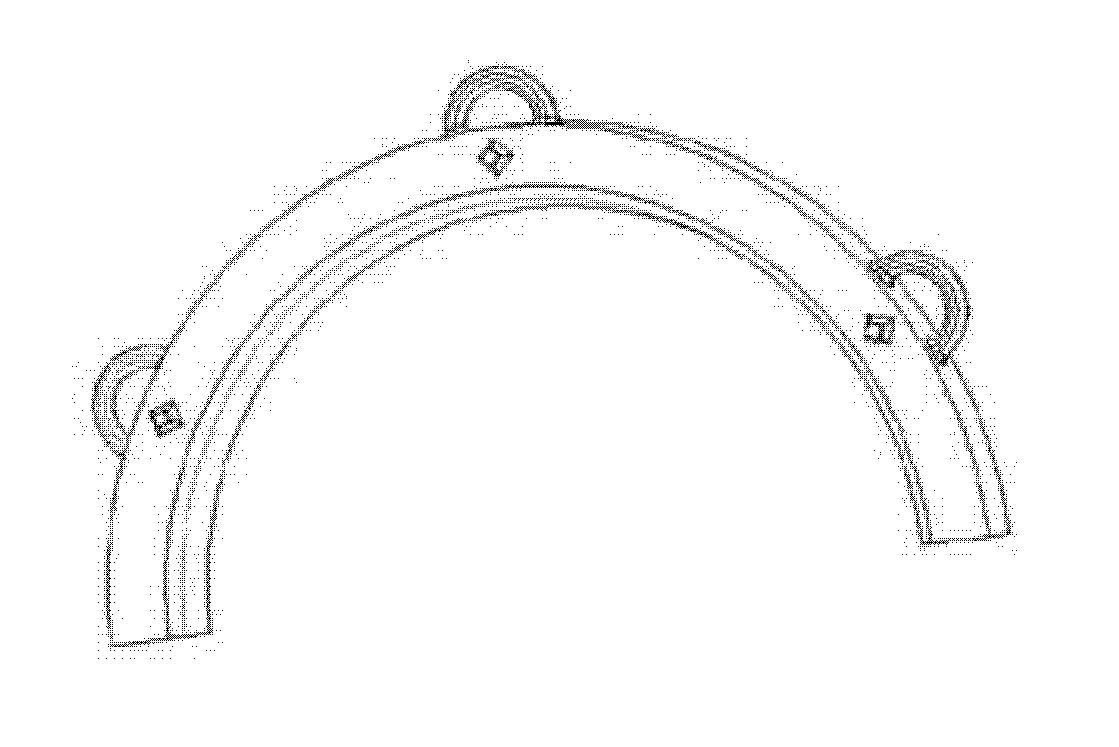

[0017] A method for casting thick-walled castings using sand-separated cold iron, the method is sequentially mold making, molding, core making, box closing, pouring and sand cleaning, such as figure 2 Shown: Before modeling, place the sand-insulated chill iron 1 on the hot joint, that is, the thick part of the casting 2, and then fix it with the boss of the sand-insulated chill iron, and put the boss on the sand-insulated chill iron close to the casting pattern of the casting Place it so that the three bosses of the sand-isolated chill iron are all close to the pattern. After placing the sand-isolated chill iron, use a rectangular strip to compact the sand layer between the chill iron and the casting pattern of the casting. The vibrating compaction platform performs micro compaction on the molding sand. The vibration frequency is 50HZ, and the micro vibration is compacted for 30 seconds. After standing for 2 hours, the box is opened, and after the box is closed, the molten iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com