Automatic bag feeding device of bag hanging manipulator as well as production method

A bag-feeding device and manipulator technology, applied in the field of automatic packaging equipment for bulk materials, can solve problems such as the failure of the filling and packaging system to achieve long-term stable operation, the vacuum adsorption and adhesion of multi-layer bags, and the manual intervention of bag opening and dislocation. The effect of manual intervention time, fully automatic operation and long working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

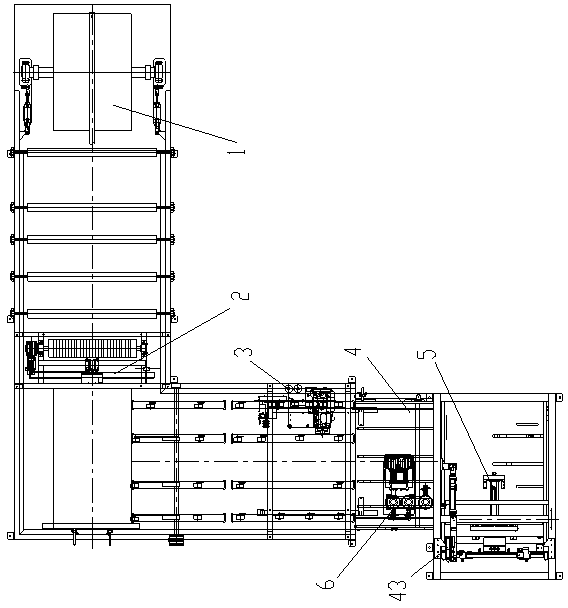

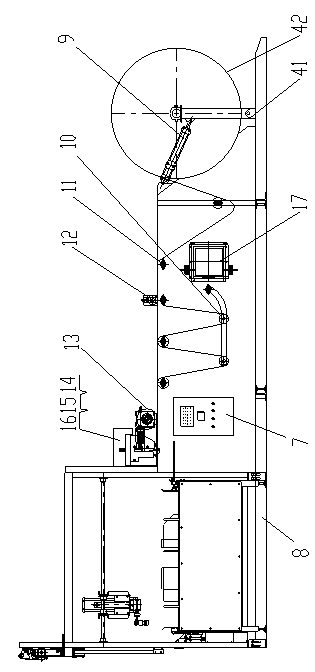

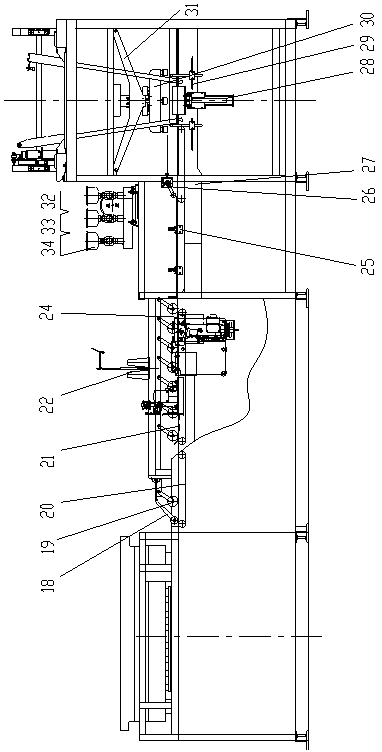

[0031] Such as figure 1 , 2 As shown, the bag-hanging manipulator automatic bag feeding device of the present invention includes a frame 8, on which a winding mechanism 1, a bag cutting mechanism 2, a sewing bottom mechanism 3 (or a heat sealing mechanism), and a transfer mechanism are sequentially arranged along the running route. 4. Vacuum adsorption system 6, bag opening manipulator 5 and other mechanisms. It also includes an automatic control system 7, which is connected to the above-mentioned winding mechanism 1, bag cutting mechanism 2, seam bottom mechanism 3, transfer mechanism 4, vacuum adsorption system 6, and bag opening manipulator 5. In this embodiment, the automatic control system 7 can adopt a PLC automatic control system, and of course a DSP control system or a PC control system can also be used. The front side of bag opening manipulator 5 is bag hanging manipulator 43.

[0032] The main components of the bag feeding device of the present invention are:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com