Sand-core molding method of ultra-large sand core structural casting

An ultra-large, sand core technology, applied in the field of sand core modeling of ultra-large sand core structure castings, can solve the problems of rising modeling and cleaning costs, inconvenient lifting and placing of sand cores, and inability of cores to go down. Lifting and placing are easy to operate, conducive to size control, and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A sand core molding method for super-large sand core structure castings, characterized in that: the method includes the following steps:

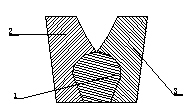

[0025] a. Sand core number: if figure 1 As shown, the middle part of the sand core is coded as 1#, the left side is 2#, and the right side is 3#;

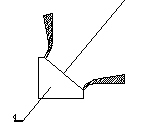

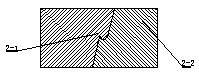

[0026] b. Making sand core: such as figure 2 Shown: make two left and right dummy cores 4 at the front and rear two large sand core nozzles, as image 3 As shown, change the original 2# sand core into two sand cores, such as Figure 4 The 3-1# and 3-2# sand cores shown are divided into upper and lower layers;

[0027] c. Make the core box: such as Figure 5 As shown, a partition 5 is added in the middle of the core box, the top frame of the core frame is made of 120*120 square steel, and the bottom bracket is made of 80*80 square steel;

[0028] d. Core-making: Use special compacting tools to ensure the compactness of key parts, the air outlet arrangement ensures the amount of san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com