Low-attenuation single-mode optical fiber

A single-mode optical fiber and optical fiber technology, applied in clad optical fiber, multi-layer core/clad optical fiber, light guide, etc., to achieve large system redundancy, reduce attenuation increase, and reduce construction and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

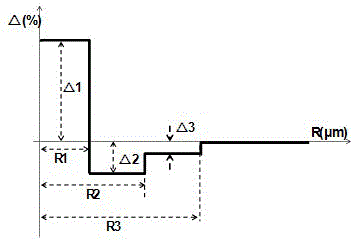

[0029] Embodiment 1: including a core layer and a cladding layer, the core layer is composed of quartz glass doped with fluorine and other dopants: there are three cladding layers outside the core layer. The first inner cladding closely surrounds the core layer, which is made by the same PCVD deposition method as the core layer; the second inner cladding is composed of fluorine-doped quartz glass; the third cladding is the outer cladding, which closely surrounds all the components of the second inner cladding The layer is a pure silicon dioxide layer prepared by OVD process, with a diameter of 125 μm.

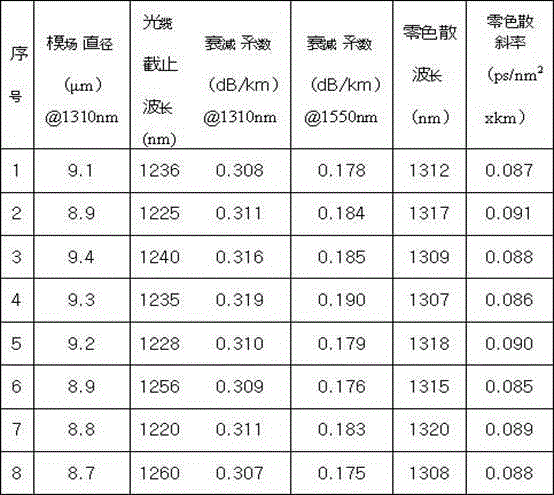

[0030]According to the technical scheme of the above-mentioned single-mode optical fiber, the parameters of the optical fiber are designed within the specified range, and the core rod is manufactured according to the design requirements of the optical fiber through the mandrel manufacturing process such as PCVD deposition process, and the sleeve process, OVD process, etc. The p...

Embodiment 2

[0040] Embodiment 2: including a core layer and a cladding layer, the core layer is composed of quartz glass doped with fluorine and other dopants: there are three cladding layers outside the core layer. The first inner cladding closely surrounds the core layer, which is made by the same PCVD deposition method as the core layer; the second inner cladding is composed of fluorine-doped quartz glass; the third cladding is the outer cladding, which closely surrounds all the components of the second cladding layer, a pure silica layer prepared by APVD or VAD, with a diameter of 125 μm.

[0041] According to the technical scheme of the above-mentioned single-mode optical fiber, the parameters of the optical fiber are designed within the specified range, and the core rod is manufactured according to the design requirements of the optical fiber through the mandrel manufacturing process such as PCVD deposition process, and the mandrel is manufactured through the sleeve process, APVD or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com