Surface-modified graphene

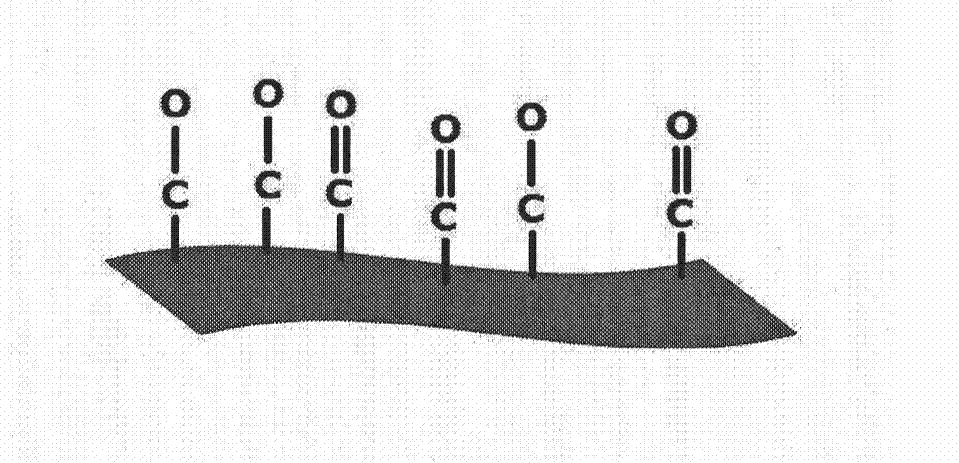

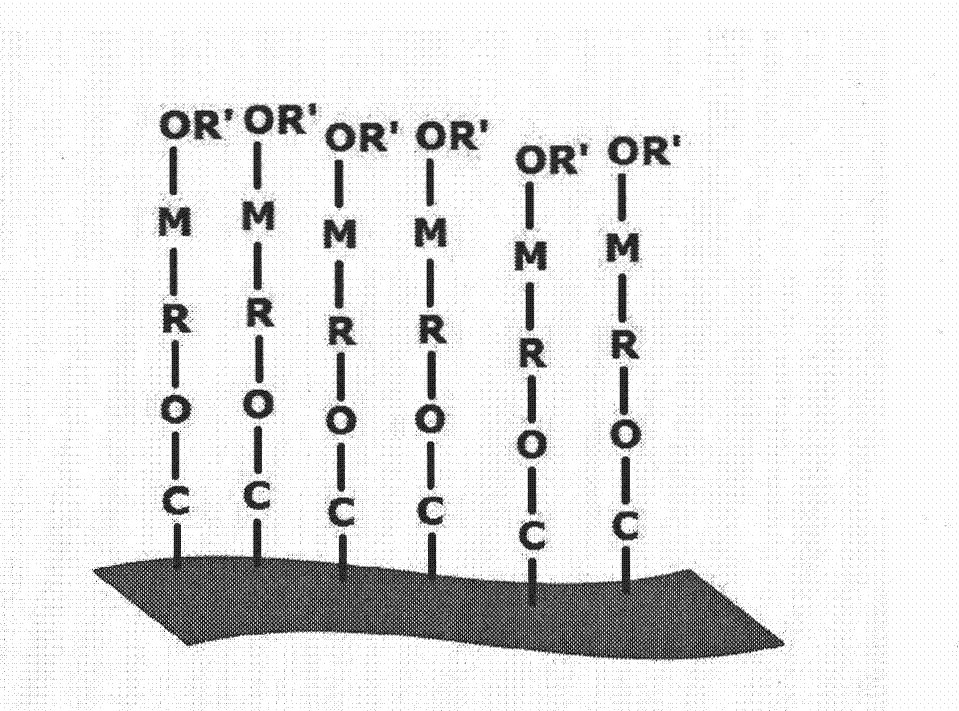

A technology of surface modification and surface modifier, applied in the direction of dyed organosilicon compound treatment, dyed low-molecular-weight organic compound treatment, fibrous filler, etc., can solve the problems of graphene surface bonding, high cost, etching method Complexity and other issues, to achieve the effects of wide applicability, improved affinity, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

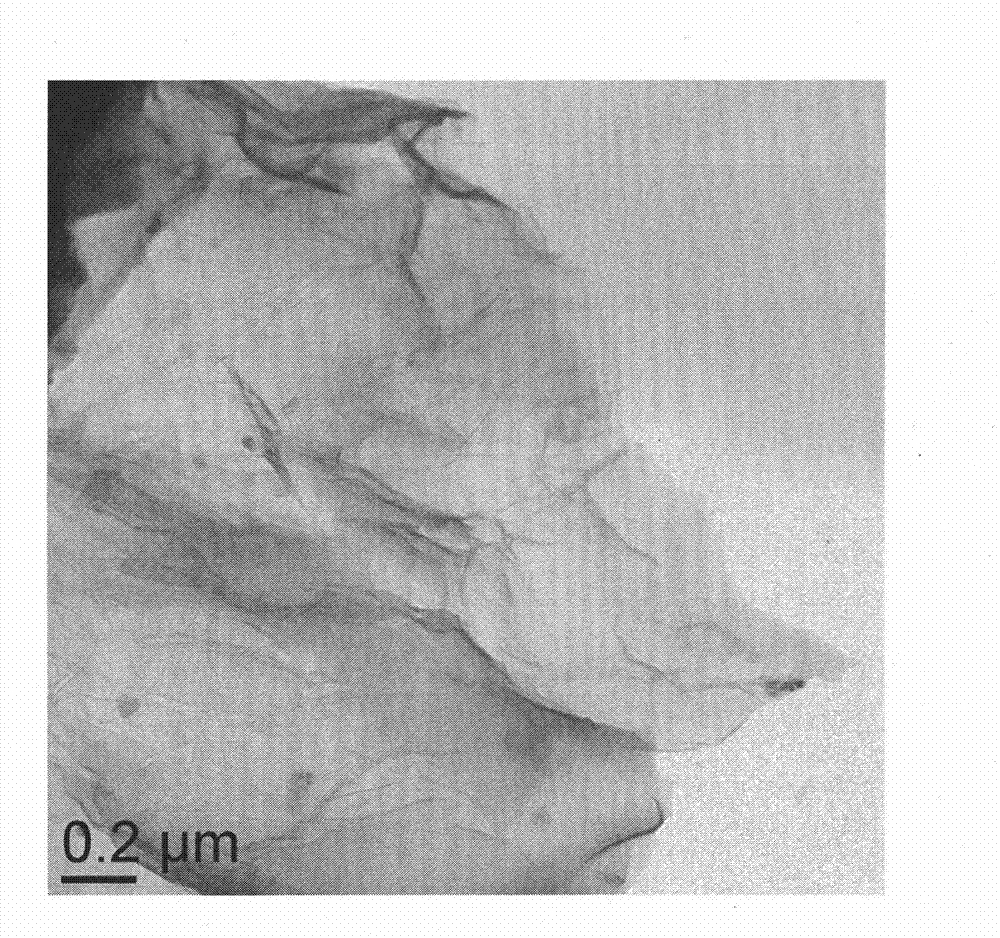

[0037]Example 1 first carries out surface analysis for the pure graphene powder after synthesis, figure 2 It is a TEM picture, showing that pure graphene is an extremely thin sheet structure with a surface area of 430m 2 / g, the oxygen content is 1.3wt%; image 3 It is the carbon element test result of XPS, and the result shows that there are still a small part of carbon oxygen or carbon hydrogen functional groups on the surface of graphene powder.

example 2

[0038] Example 2 adopts coupling agent aminosiloxane (3-Aminopropyl triethoxysilane) as a surface modifier, and its structure is Si(C 3 h 6 N)(C 2 h 5 O) 3 , the implementation method is to add the surface modifier into a mixed solution of ethanol and water, then add graphene powder for mixing and stirring, and finally take out the powder by suction and filtration and heat and dry in an oven to obtain the surface modified Graphene powder. Figure 4 It is the modified graphene TEM image, which shows that there is another layer of film on the surface of the graphene powder, which may be the coating of the surface modifying agent. Figure 4 EDS analysis at the circles can detect such as Figure 5 The Si element signal shown at the same time proves that there is a surface modifier on the surface of the graphene powder; Figure 6 (A) and Figure 6 (B) are XPS diagrams of the graphene powder after modification, and it can be seen from the figure Signals of silicon and nitrogen e...

example 3

[0039] Example 3 adopts coupling agent tetrabutyloxytitanium (Titanium n-butoxide) as surface modifier, and its structure is Ti(C 4 h 9 O) 4 , the implementation method is to add the surface modifier into an isopropanol solvent, then add graphene powder for mixing and stirring, and finally take out the powder by suction and filtration and heat and dry in an oven to obtain surface-modified graphene Powder. Figure 7 It is the XPS diagram of the modified graphene powder. From the figure, it can be seen that the signal of titanium element appears on the surface of the graphene powder, which proves that the surface modifier is definitely coated on the surface of the graphene powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com