Activation method of catalyst

An activation method and catalyst technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of improving the dispersion state and increasing the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

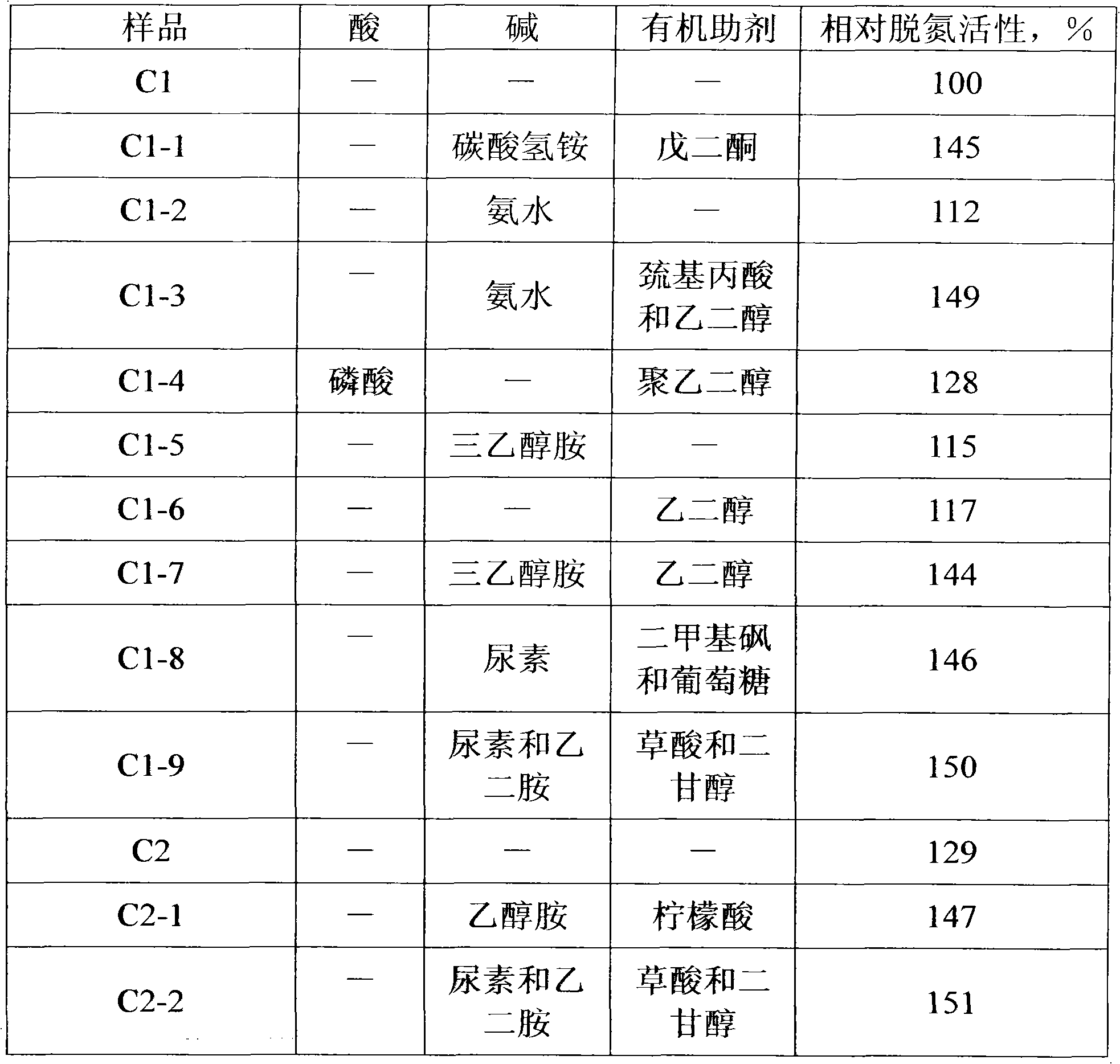

Embodiment 1

[0022] Take a deactivated hydrotreating catalyst with a carbon deposit of 4.6%, and perform charcoal regeneration treatment under an oxygen-containing atmosphere. Take 500mL deactivated catalyst, raise the temperature to 500°C at a heating rate of 3°C / min, and keep the temperature at 500°C for 3 hours. The obtained sample is named C1, and its carbon content is 0.15%, MoO 3 The NiO content is 21.4%, and the NiO content is 3.6%.

[0023] Regenerant C1 was activated with ammonium bicarbonate and pentanedione. Take the mixed solution of ammonium bicarbonate and pentanedione to spray and immerse C1 in an equal volume. The molar ratio of ammonium bicarbonate and pentanedione in the solution to the total metal atoms on the regeneration agent is 0.4:0.08:1. After the sample is placed for 8 hours, 120 °C for 4 hours, and the obtained catalyst was designated as C1-1.

Embodiment 2

[0025]Activate the regenerant C1 with ammonia water, mercaptopropionic acid and ethylene glycol. Spray and immerse C1 in an equal volume of ammonia water solution, wherein the molar ratio of ammonia water to the total metal atoms on the regenerant is 0.8:1. After the sample is left for 18 hours, it is dried at 120°C for 2 hours. The obtained sample is named C1-2. Take an equal volume of mixed solution of mercaptopropionic acid and ethylene glycol and impregnate C1-2, wherein the molar ratio of mercaptopropionic acid and ethylene glycol to the total metal atoms on C1-2 is 0.1:0.3:1, and place the sample at 80°C for 4 After 1 hour, it was dried at 120°C for 4 hours, and the obtained catalyst was designated as C1-3.

Embodiment 3

[0031] Catalyst C2 is activated with ethanolamine and citric acid. Take the mixed solution of ethanolamine and citric acid and spray and immerse C2 in an equal volume. The molar ratio of ethanolamine and citric acid in the solution to the total metal atoms on the catalyst is 0.1:0.6:1. After the sample is left for 8 hours, it is dried at 120°C for 4 hours to obtain The catalysts are respectively designated as C2-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com