Spectral beam combining device for realizing spectral width compression through two-time diffraction by using grating and reflecting element

A technology of reflective elements and spectral beam combining, applied in optical components, optics, instruments, etc., can solve the problems of increased optical path, limited, incomplete feedback, etc., to achieve the improvement of grating dispersion ability, power and brightness, and beam combination. Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

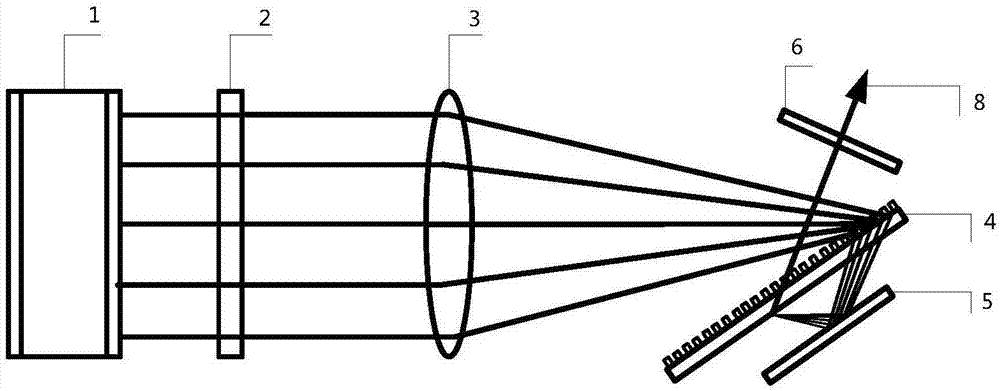

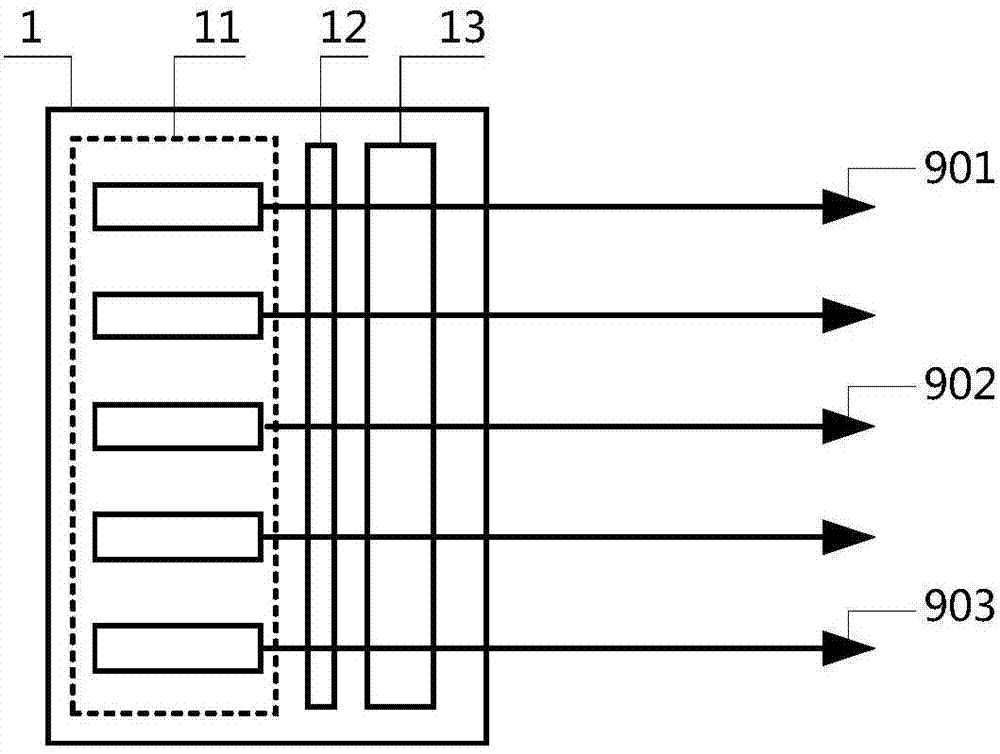

[0036] Embodiment 1: as figure 1 as shown, figure 1 It is the first embodiment of the present invention, which uses a grating and a reflector to realize a spectral beam combining device for two times of diffraction and compressed spectral width. The device includes a semiconductor laser light source 1, a slow axis collimating cylindrical lens 2, a conversion lens 3, a transmission grating 4, Mirror 5, output coupling mirror 6. The semiconductor laser light source 1 is located at the front focal point of the conversion lens 3, the transmission grating 4 is located in front of the rear focus of the conversion lens 3, and the semiconductor laser light source 1 emits multiple beams of parallel light.

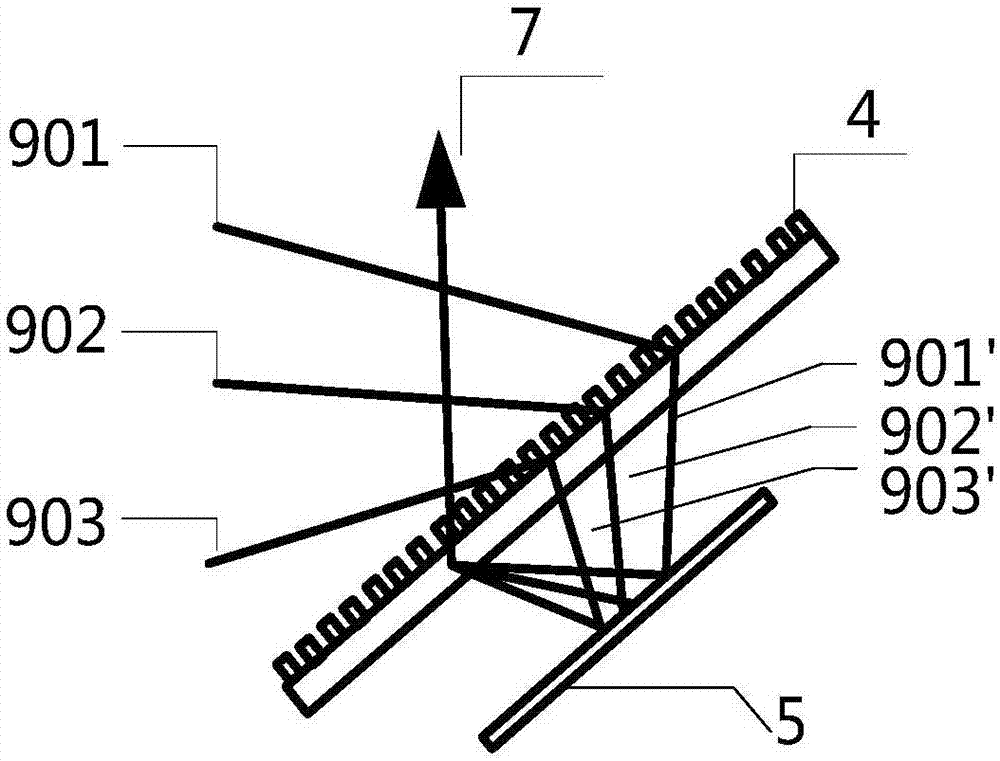

[0037] Such as figure 2 as shown, figure 2 For the action process of each light-emitting unit of the present invention, the transmission grating 4 and the reflector 5, the light beams of each unit are incident on the transmission grating 4 after being converged by the conversion ...

Embodiment 2

[0039] Embodiment 2: as Figure 4 as shown, Figure 4 It is the second embodiment of the present invention, using a diffraction grating and a right-angle prism to realize a spectral beam combining device that compresses the spectral width of two diffractions, and the device includes a semiconductor laser light source 1, a slow-axis collimating cylindrical lens 2, a conversion lens 3, and a diffraction grating 4 ', rectangular prism 5', output coupling mirror 6. The semiconductor laser light source 1 is located at the front focal point of the conversion lens 3, and the diffraction grating 4' is located in front of the rear focus of the conversion lens 3, and the semiconductor laser light source 1 emits multiple beams of parallel light.

[0040] Such as Figure 5 as shown, Figure 5 For the action process of each light-emitting unit of the present invention, the diffraction grating 4' and the rectangular prism 5', after each unit is converged by the conversion lens 3, it is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com