Inferior coker gas oil hydrotreatment method

A coking wax oil and hydrotreating technology, which is applied in the fields of hydrotreating process, chemical instruments and methods, and hydrocarbon oil treatment, can solve the problems of processing and utilization limitations, pollute the environment, poor cracking performance, etc., and increase the distribution range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

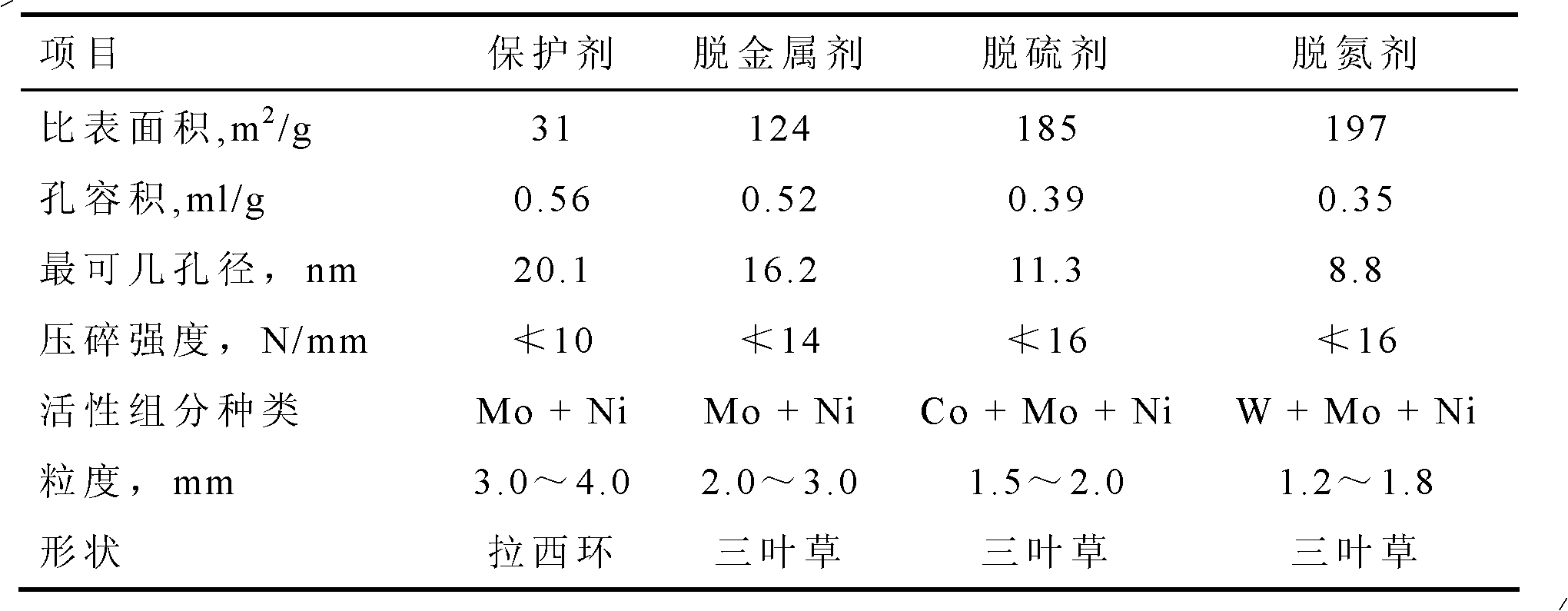

Method used

Image

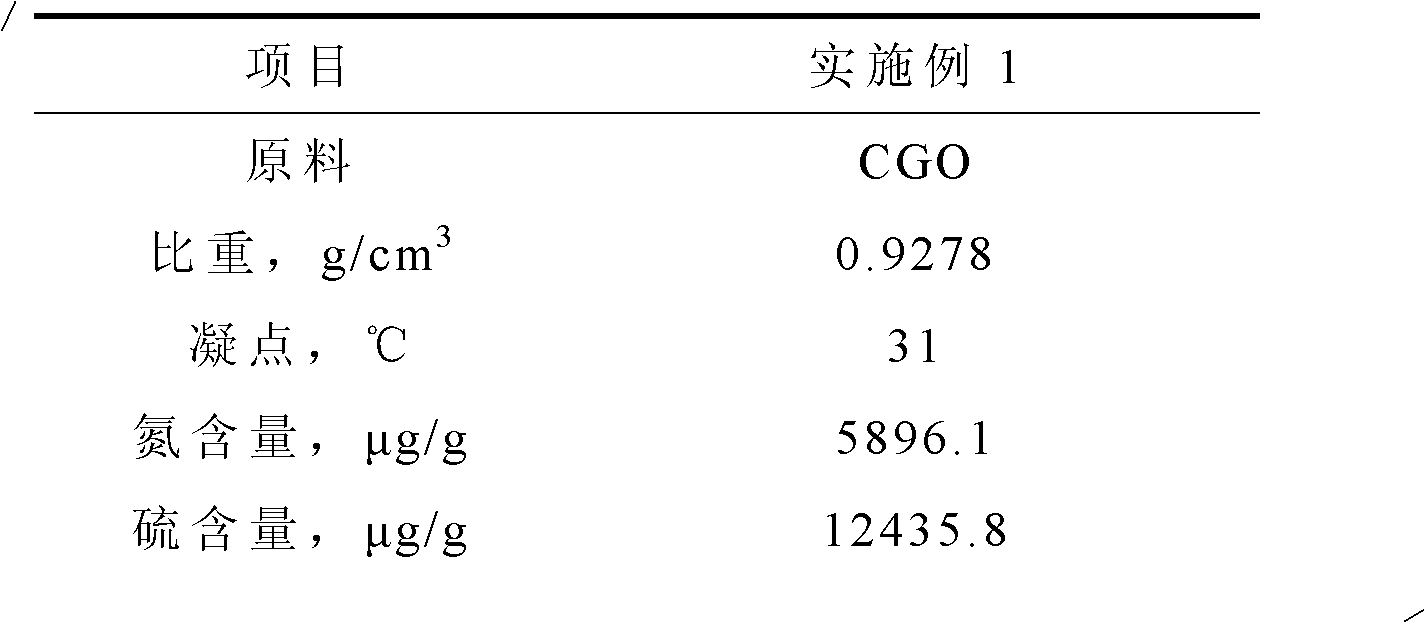

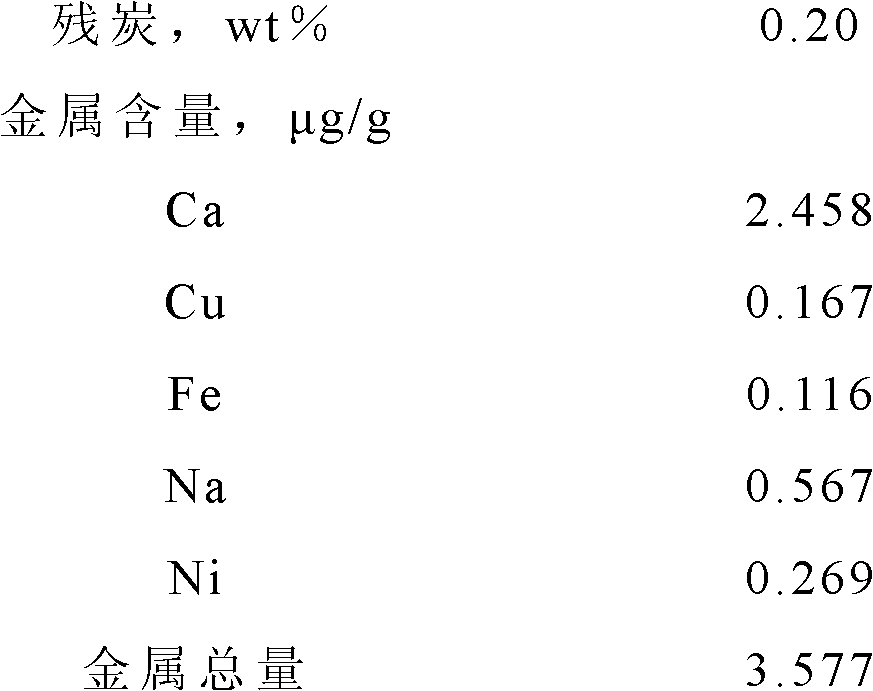

Examples

Embodiment 1

[0027] (1) Preparation of protective agent

[0028] Mix macroporous pseudo-boehmite, silica sol, turmeric powder, citric acid and magnesium-containing aqueous solution evenly, extrude and dry, and roast at 600°C to 1200°C to obtain magnesium-aluminum spinel-macropore Alumina carrier, after the carrier has been modified by organosilicon, a metal solution containing a certain amount of active Mo-Ni is added to the carrier, aged for 12 hours, dried at 100°C to 120°C for 14 hours, and roasted at 500°C for 5 hours in air to obtain the protective agent.

[0029] (2) Preparation of hydrodemetallization agent

[0030] First, surface-treat the prepared magnesia-aluminum spinel-macroporous alumina carrier with organic silicon, dry it at 30°C-50°C, then treat it with ethanol solution of surfactant, and dry it at 30°C-50°C Finally, add a metal solution at room temperature or under heating conditions to prepare a solution, add a certain amount of active Mo-Ni metal solution on the carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com