Novel linear motion plane grinding device

A linear motion and plane grinding technology, which is applied in the direction of grinding device, grinding drive device, grinding/polishing safety device, etc., can solve the problems of low efficiency and low grinding precision, and achieve stable transmission, high grinding precision and efficiency, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

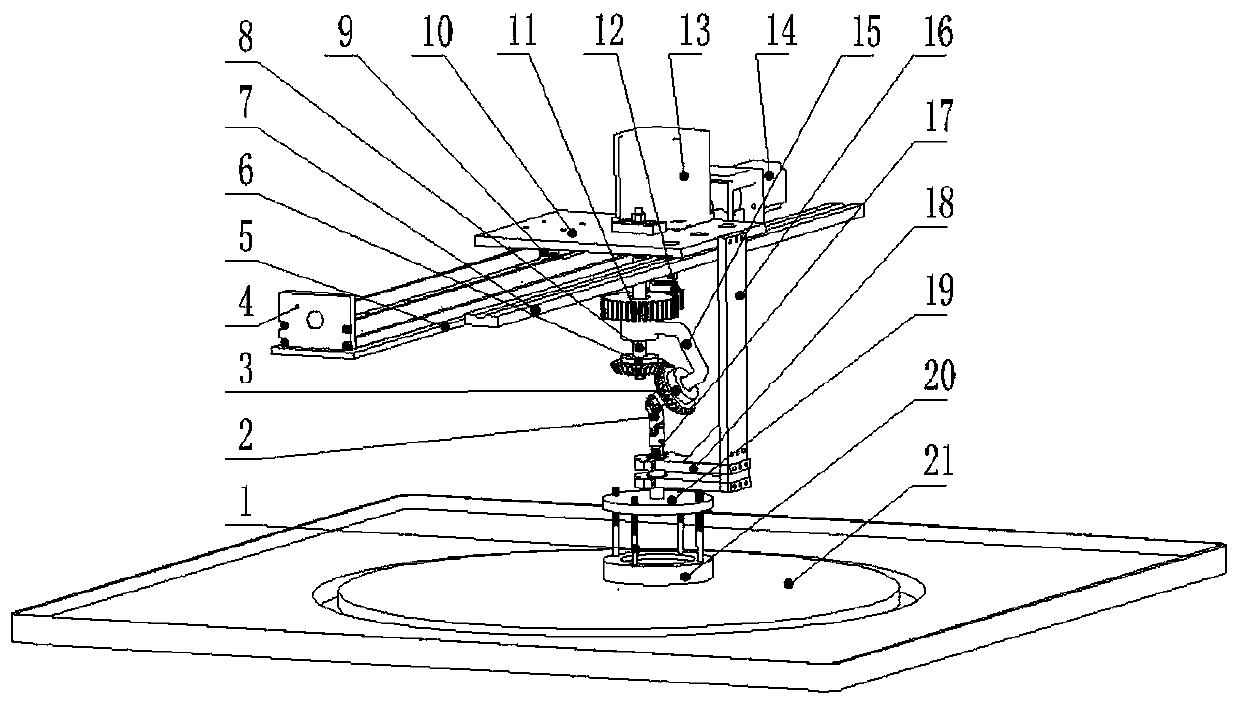

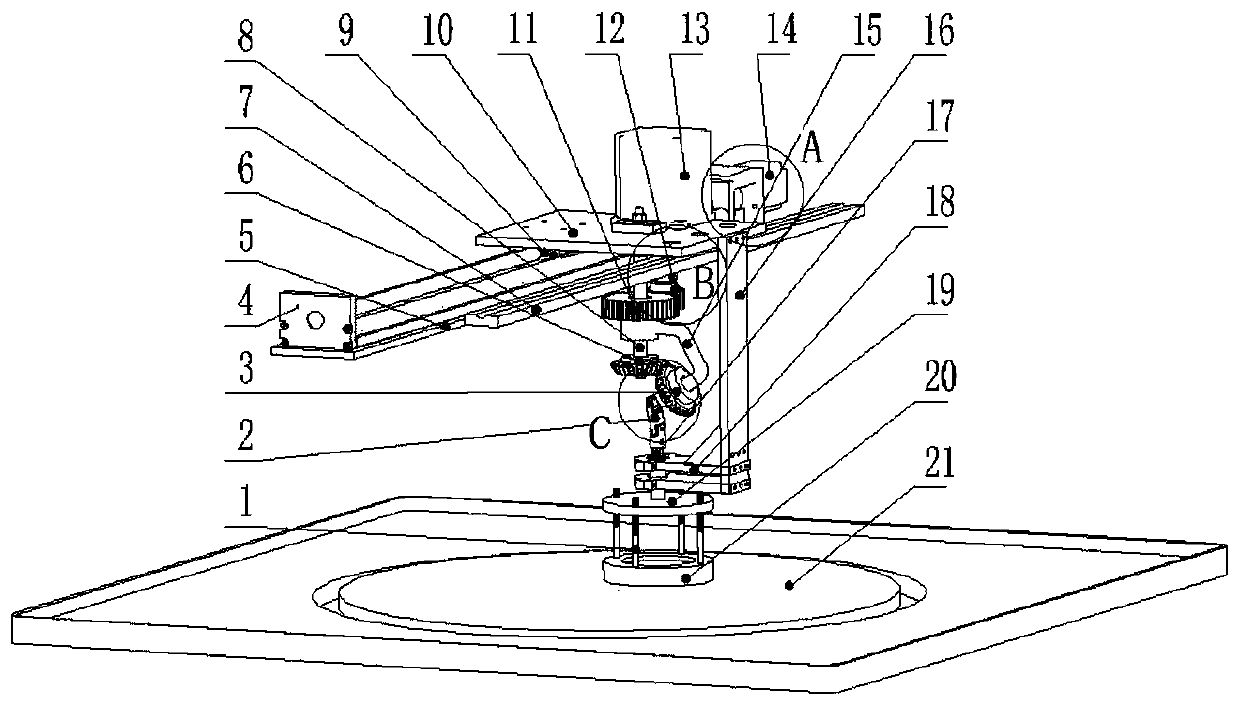

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

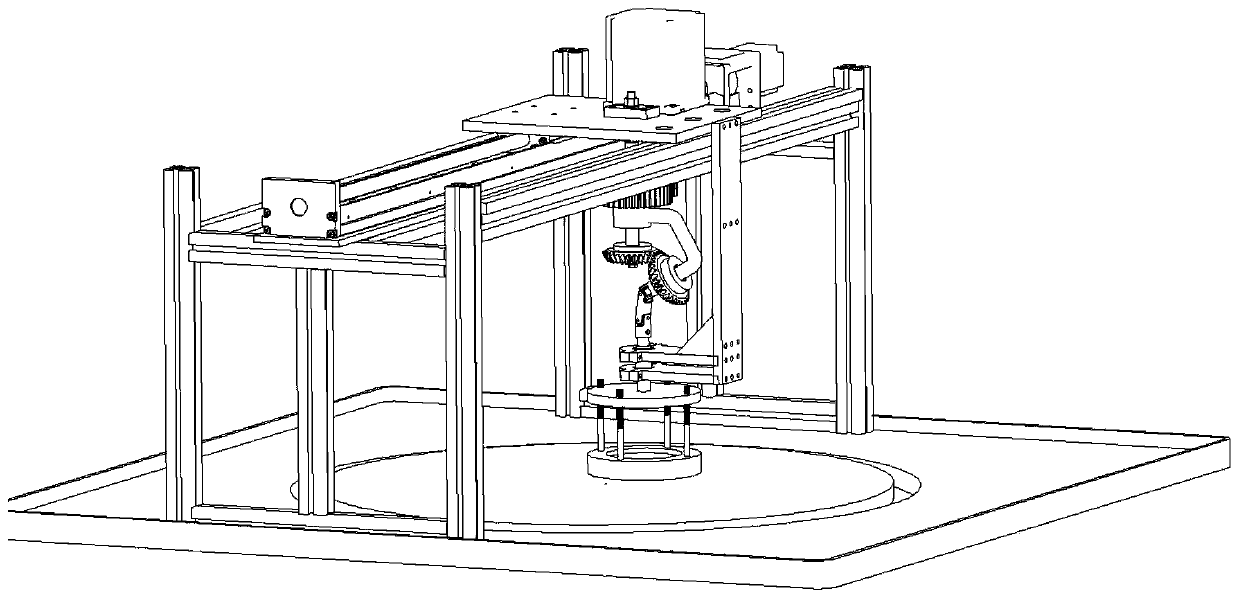

[0025] refer to Figure 1 ~ Figure 4 , a new type of linear motion surface grinding device, including plunger, universal joint, bevel gear II, screw slide table, slide table back plate, bevel gear I, linear guide rail, shaft II, slider, motor plate, cylindrical gear Ⅱ, cylindrical gear Ⅰ, motor Ⅱ, motor Ⅰ, bent shaft, fixed vertical plate, shaft Ⅳ, fixed horizontal plate, chuck, workpiece disc, grinding disc, coupling Ⅰ, shaft Ⅰ, bullseye wheel, shaft III and Coupling II.

[0026] The output shaft of the motor I14 is fixedly installed on the screw shaft of the screw slide 4 through the coupling II26, and the motor seat of the motor I4 is fixed and installed on the corresponding position of the screw slide 4 by bolts; the slider 9. The coaxial center is installed on the lead screw of the lead screw slide 4, and is fixedly connected with a section of the motor plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com