Preparation method of conductive macromolecule non-covalent functionalized graphene modified electrokinetic energy conversion polymer material

A technology of non-covalent modification and polymer materials, which is applied in the field of non-covalent modification of conductive polymer graphene modified electrokinetic energy conversion polymer materials, which can solve the limitations of material applications, reduction of electrical breakdown strength, dielectric loss and Improve the dispersion, reduce the dielectric loss and loss modulus, and increase the dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: Preparation of PEDOT:PSS-RGO (1)

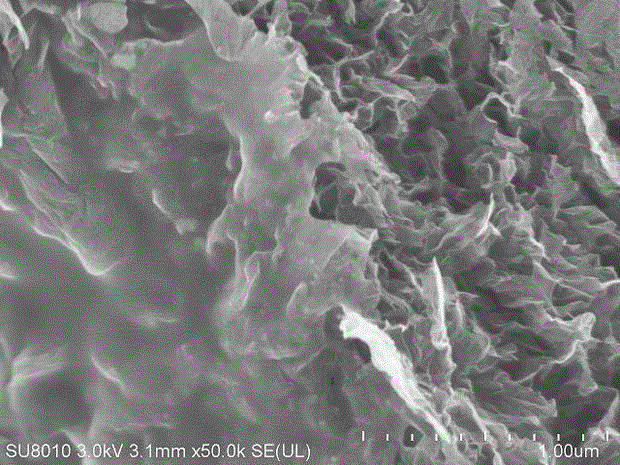

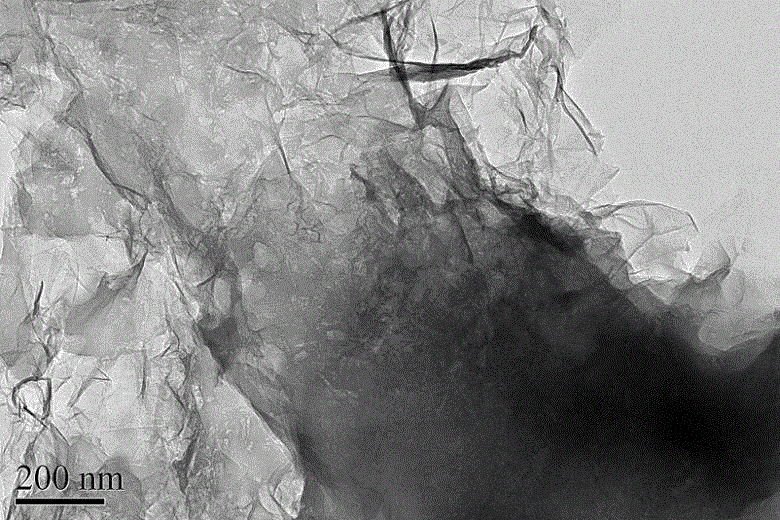

[0029] Add 10mL of deionized water to a 25mL small beaker, then add 50mg of graphene and disperse ultrasonically for 6h, then add 3.5mL of PEDOT:PSS (density 1g / mL, solid content 1.4%) solution with a needle syringe, and ultrasonically disperse After 4 hours, the mixed solution was poured onto a quartz glass with a diameter of 6 cm and a smooth bottom surface, and placed in a drying oven at a low temperature of 50°C for solvent evaporation to induce self-assembly for 24 hours to obtain poly(3,4-ethylenedioxythiophene):poly Non-covalent modification of graphene PEDOT with styrene sulfonic acid: PSS-RGO (1). The scanning electron microscopy and transmission electron microscopy images of the prepared PEDOT:PSS-RGO show that the nanomaterial presents a "sandwich" structure, and a thin layer of conductive polymer is evenly coated on the surface of the graphene sheet.

example 2

[0030] Example 2: Preparation of PEDOT:PSS-RGO (2)

[0031] Add 10mL of deionized water to a 25mL small beaker, then add 50mg of graphene and disperse for 6 hours with ultrasonic assistance, then add 3.5mL of PEDOT:PSS (density 1g / mL, solid content 1.4%) solution with a needle syringe, and ultrasonically disperse After 4 hours, the mixed solution was poured onto a smooth bottom surface of quartz glass, and placed in a drying oven at a low temperature of 50°C for solvent evaporation to induce self-assembly for 24 hours to obtain poly(3,4-ethylenedioxythiophene):polystyrenesulfonate Acid non-covalent modification of graphene PEDOT:PSS-RGO (2).

example 3

[0032] Example 3: Preparation of PEDOT:PSS-RGO (3)

[0033] Add 10mL of deionized water to a 25mL small beaker, then add 50mg of graphene and disperse ultrasonically for 6h, then add 0.7mL of PEDOT:PSS (density 1g / mL, solid content 1.4%) solution with a needle syringe, and ultrasonically disperse After 4 hours, the mixed solution was poured onto a smooth bottom surface of quartz glass, and placed in a drying oven at a low temperature of 50°C for solvent evaporation to induce self-assembly for 24 hours to obtain poly(3,4-ethylenedioxythiophene):polystyrenesulfonate Acid non-covalent modification of graphene PEDOT:PSS-RGO (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loss modulus | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com