Direct-selected coarse-gauge automatic flat knitting machine

A coarse-gauge, automatic technology, which is applied in the field of direct-selection coarse-gauge automatic flat knitting machines, can solve the problems of putting coarse-gauge automatic flat knitting machines on the market, and achieves a reduction in shape, manufacturing difficulty and cost, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing of specification sheet and embodiment:

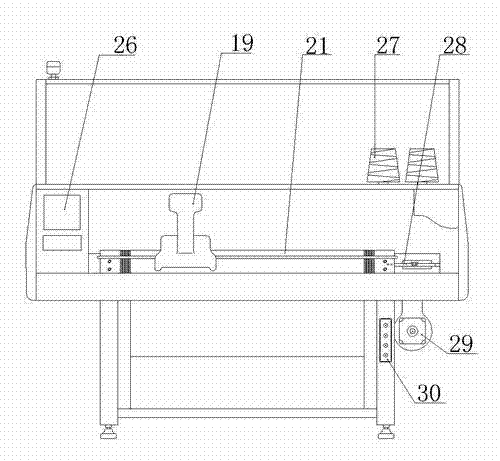

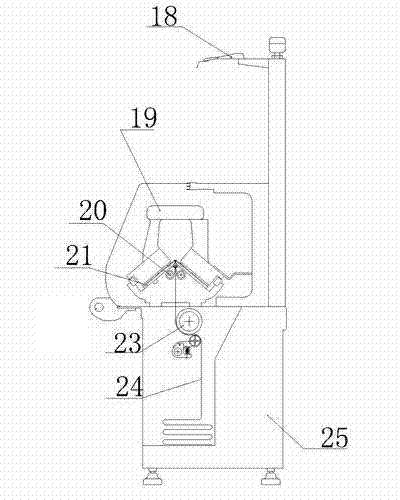

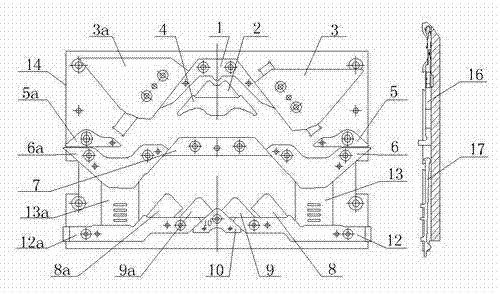

[0040] Such as Figure 1-12 As shown, a direct-selection type coarse gauge automatic flat knitting machine includes a frame 25, which cooperates with a knitting system 19, a transmission system 29, a coiling system, a liquid crystal display screen 26, a bed shifting system 28, and an electronic device arranged on the frame 25. Control system and yarn delivery system 18, the knitting system 19 includes a needle track control mechanism, a needle bed 21 cooperating with the needle track control mechanism, and knitting needles 16 and jacquard needles 17 arranged on the needle bed 21, The needle trajectory control mechanism includes a triangular base plate 14, a left needle selector 13a fixedly arranged at the left and right lower corners of the triangular base plate 14, a right needle selector 13, and knitting needles arranged on the upper,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com