Polished tile, and preparation method and application thereof

A technique for polishing bricks and adobes, which is applied in the field of ceramic building materials, and can solve problems such as affecting the appearance, poor wear resistance and poor antifouling performance of glazed bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

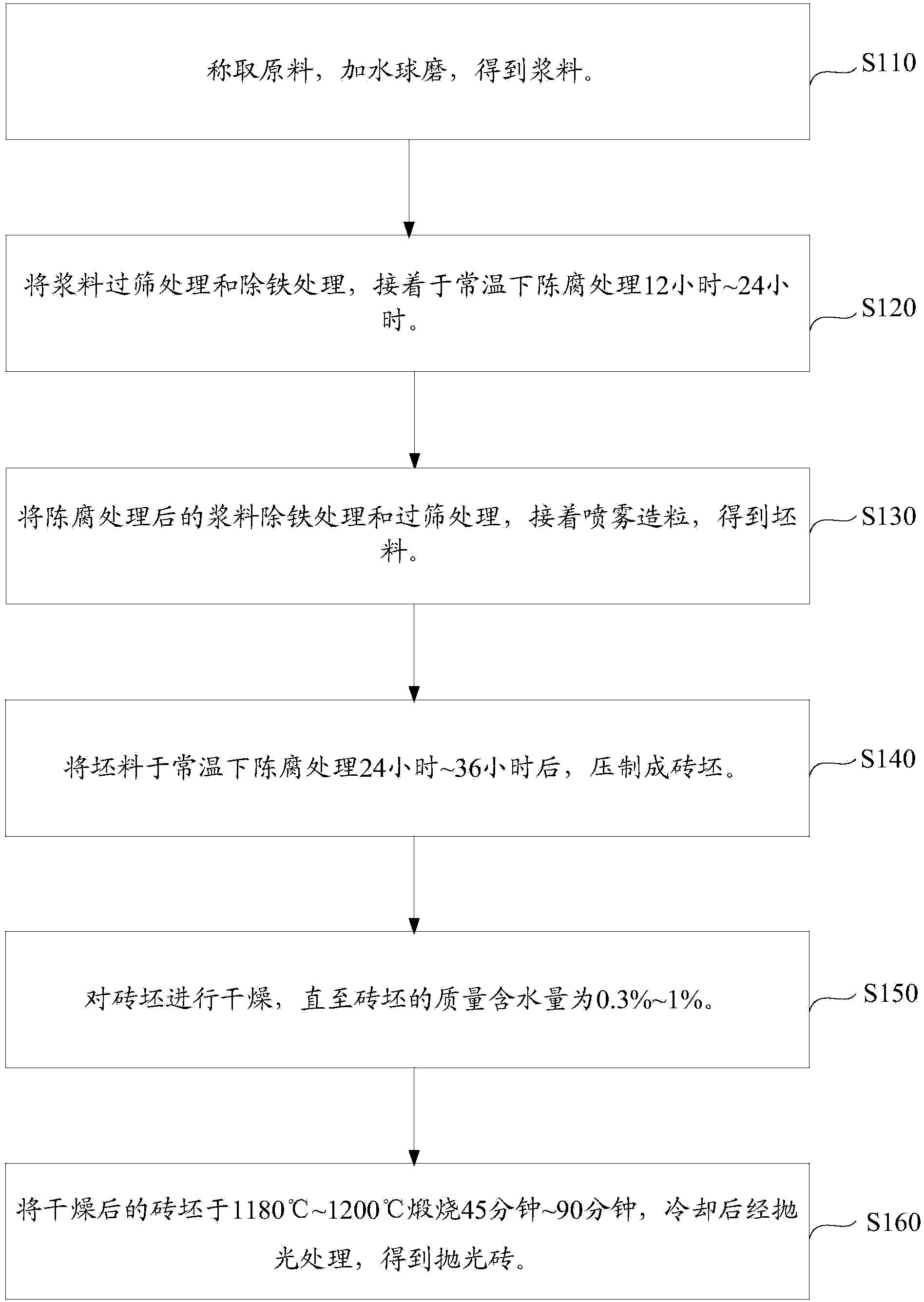

[0037] Such as figure 1 Shown, the preparation method of the polished tile of an embodiment, comprises the steps:

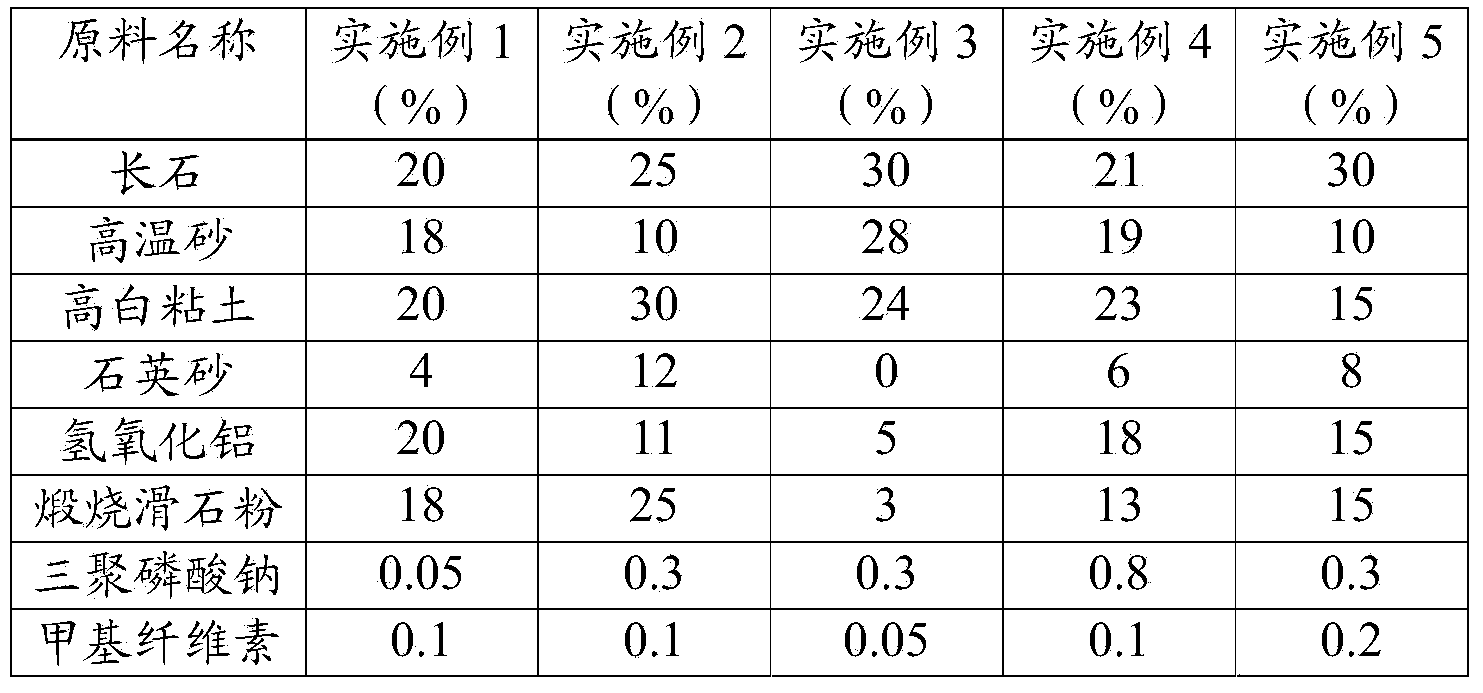

[0038] Step S110: weighing raw materials, adding water and ball milling to obtain slurry. Among them, the mass percentage of raw materials is as follows: feldspar 20%~30%, high temperature sand 10%~28%, high white clay 15%~30%, quartz sand 0~12%, aluminum hydroxide 5%~20%, calcined Talc powder 3%~25%, sodium tripolyphosphate 0.5%~0.8% and methyl cellulose 0.05%~0.2%. The fineness of the slurry is 0.5% to 1.2% on a 250-mesh sieve. The mass percentage of water in the slurry is 32% to 34%.

[0039] By adding water and ball milling, the slurry has a certain flow rate and is more uniform. The fineness of ball milling is 0.5%~1.2% of 250 mesh sieve, which can make the whiteness of polished tiles more uniform and the texture more delicate. Specifically, the ball milling time is 12 hours to 18 hours.

[0040] Step S120: Sieving the slurry and removing iron, and the...

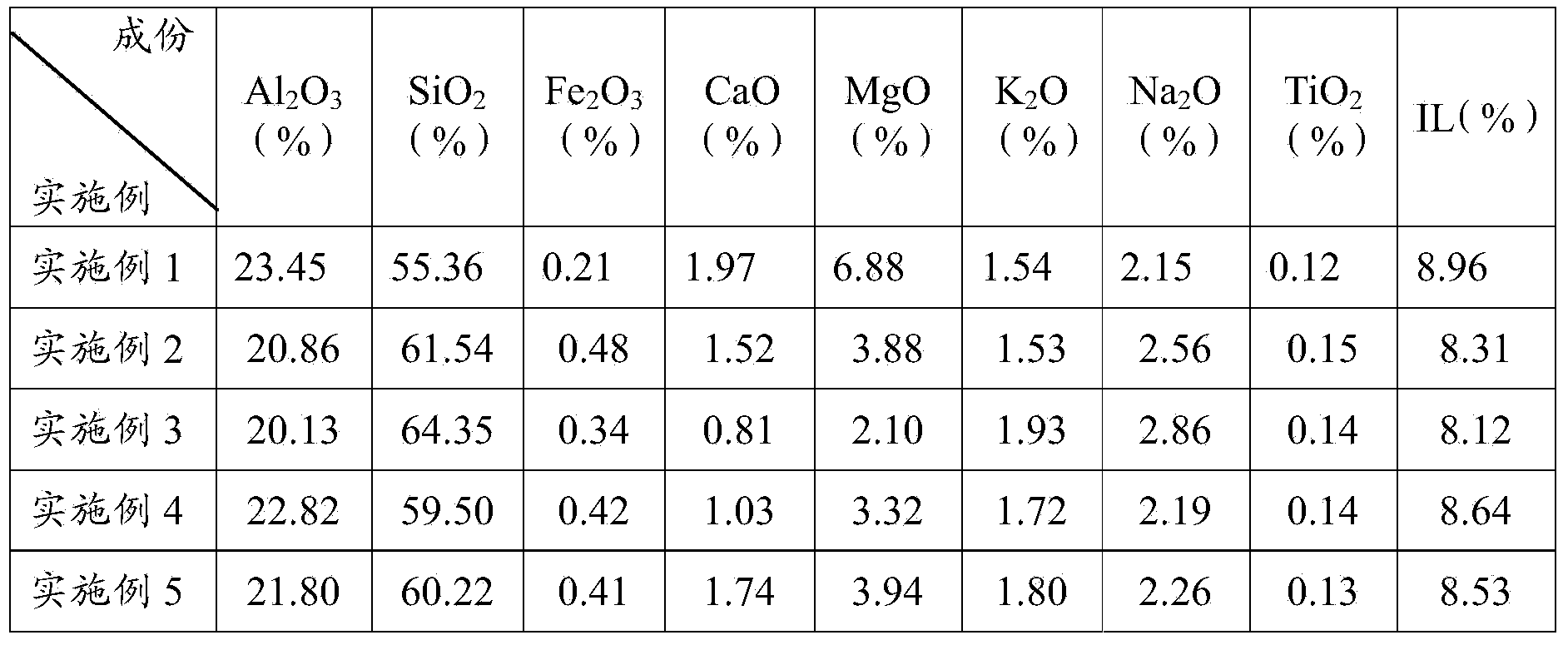

Embodiment 1

[0059] The preparation of the polished brick of the present embodiment is as follows:

[0060] (1) Weigh each raw material according to the mass percentage in Table 1, send it into a ball mill, and add water to ball mill for 12 hours to obtain a slurry. Wherein, the mass percent content of water in the slurry is 32%, and the ball milling fineness is 0.5% over a 250-mesh sieve.

[0061] (2) Pass the slurry in step (1) through an 8-mesh sieve and put it into the slurry tank, then use an automatic iron remover to remove iron, then pass through a 60-mesh sieve, use the automatic iron remover to remove iron again, and then pass through 80-mesh sieve, and then aged at room temperature for 12 hours.

[0062] (3) Use an automatic iron remover to remove iron from the stale treated slurry in step (2), pass it through a 120-mesh sieve, and then use a spray tower to spray and granulate to obtain a billet, wherein the mass percentage of water in the billet is 6.5 %, the particle gradatio...

Embodiment 2

[0068] The preparation of the polished brick of the present embodiment is as follows:

[0069] (1) Weigh each raw material according to the mass percentage in Table 1, send it into a ball mill, and add water to ball mill for 13 hours to obtain a slurry. Wherein, the mass percent content of water in the slurry is 34%, and the ball milling fineness is 0.5% over a 250-mesh sieve.

[0070] (2) Pass the slurry in step (1) through a 10-mesh sieve and put it into the slurry tank, then use an automatic iron remover to remove iron, then pass through an 80-mesh sieve, use the automatic iron remover to remove iron again, and then pass through 100-mesh sieve, and then aged at room temperature for 24 hours.

[0071] (3) Use an automatic iron remover to remove iron from the stale treated slurry in step (2), pass it through a 100-mesh sieve, and then use a spray tower to spray and granulate to obtain a billet, wherein the mass percentage of water in the billet is 7 %, the particle gradatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com