Pistol-drill clamping mechanism suitable for milling of circular groove

A clamping mechanism, pistol drill technology, applied in portable drilling rigs, manufacturing tools, portable mobile devices, etc., can solve the problems of inconvenient connection of other equipment or tooling, affecting the processing accuracy of materials, etc., to achieve simple structure, high processing accuracy, good quality The effect of milling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

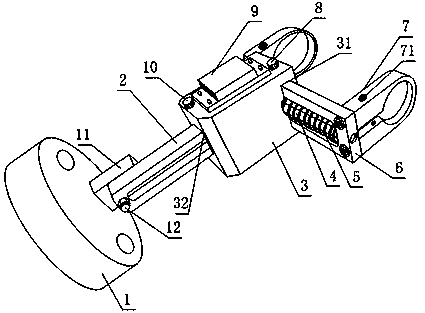

[0022] Such as figure 1 , a pistol drill clamping mechanism suitable for annular groove milling provided by the present invention, including at least two hoop-shaped hoop parts 7, a first sliding seat 2, a second sliding seat 6, and a slider 3 And the base 1, the base 1 is also provided with a hinged rod 11, the hoop parts 7 are parallel to each other and are respectively fixed on one end of the second sliding seat 6, both on the first sliding seat 2 and the second sliding seat 6 A slide rail is provided, and the slide block 3 is provided with a first slide groove 31 and a second slide groove 32 respectively matched with the slide rails, and the two slide rails are partially located in the first slide groove 31 or the second slide groove 32 respectively. , and the first chute 31 and the second chute 32 are perpendicular to each other, the slider 3 can slide along the slide rail, the hinge rod 11 or the first sliding seat 2 is also provided with a hinge nail 12, the hinge rod 1...

Embodiment 2

[0025] This embodiment is further limited on the basis of embodiment 1: as figure 1 , the hoop portion 7 is a U-shaped structure provided with an annular through hole, and the hoop portion 7 is also provided with a tightening bolt hole 71 for adjusting the size of the annular through hole, the hoop portion 7 Be connected with the second sliding seat 6 by bolts.

[0026] The hoop portion 7 of the above structural form is simple in structure, and the annular through hole is used to match the shell of the pistol drill, and the hoop bolt hole 71 is used to install the locking bolt. After the pistol drill is put into the two hoop portions 7, The size of the annular through hole is reduced by the locking bolt, so that the present invention is suitable for the installation of pistol drills within a certain size range; at the same time, the hoop part 7 and the second sliding seat 6 are in a bolted structural form, which is convenient for replacing different The size of the hoop porti...

Embodiment 3

[0028] The present embodiment is further limited on the basis of embodiment 1: as figure 1 , in order to enable the pistol drill to automatically reset on its axis, so as to optimize the processing efficiency of the present invention in the axial direction of the hole, the second sliding seat 6 is block-shaped, and the first chute on the slider 3 31 is a T-shaped slot, and a spring 5 fixedly connected to it at one end is also arranged on the second sliding seat 6 , and the other end of the spring 5 is in contact with the slider 3 .

[0029] In order to make the present invention applicable to the drilling of deep holes, that is, to extend the length of the slide rail 61, in order to make the longer spring 5 not bend in the deformation process in this case, so as to facilitate the stability of the present invention's work, the described The second sliding seat 6 is also provided with a guide rod 4 which is threaded or bolted, the spring 5 is sleeved on the guide rod 4 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com