Method for preparing high-performance permanent magnet via diffusion permeation treatment of sintered neodymium iron boron recycled waste materials

A technology for recycling waste and NdFeB, which is applied in the field of rare earth magnetic materials, can solve the problems of complex processing methods, complex production processes, and environmental pollution, and achieve simple powder-making and molding processes, high powder-making efficiency, and simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

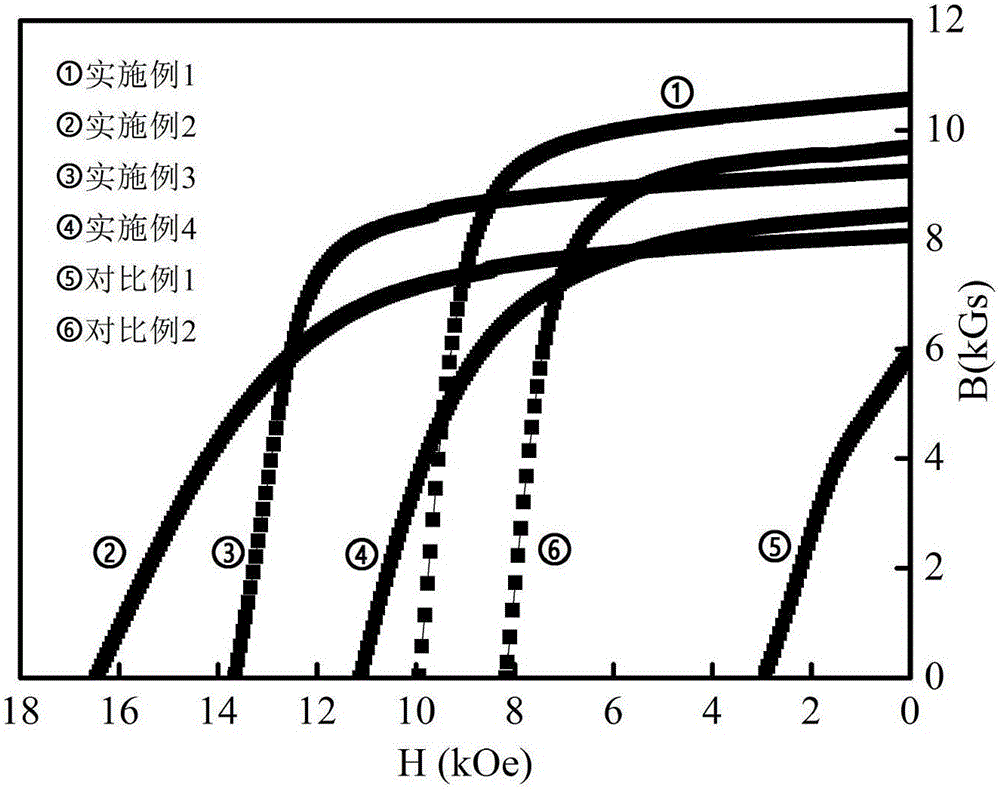

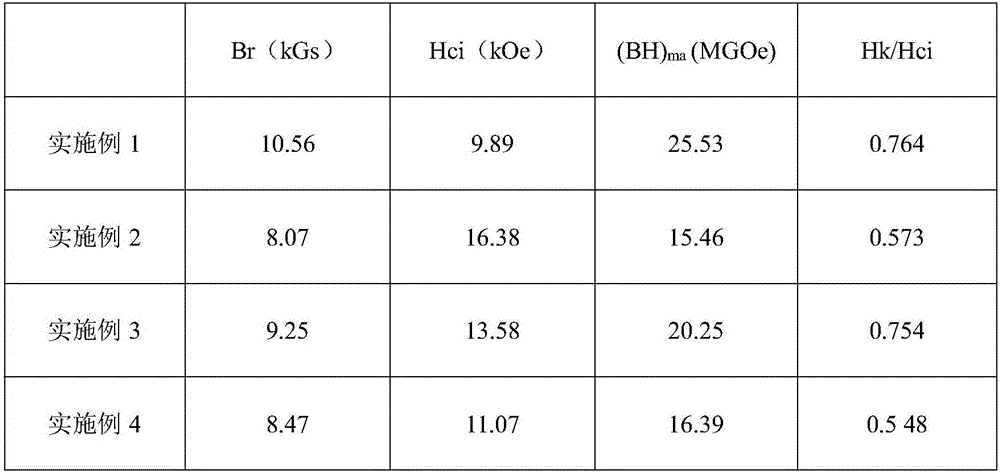

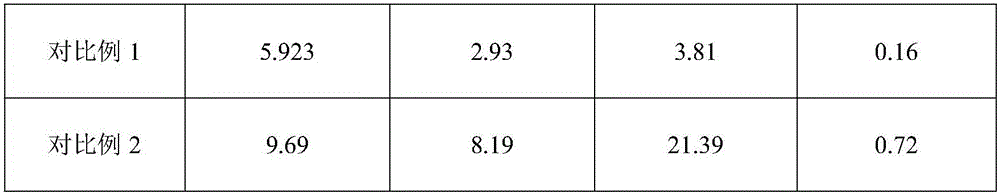

Embodiment 1

[0027] (1) The cleaned raw materials are mechanically crushed under nitrogen protection, passed through a 60-mesh sieve, and the powder under the sieve is raw material magnetic powder;

[0028] (2) Combine 99g of the raw material magnetic powder obtained in step (1) with 1g of Dy 2 o 3 The diffusing agent powder is added into the mixer and mixed for 2 hours to obtain mixed magnetic powder;

[0029] (3) Orientate and press the mixed magnetic powder obtained in step (2) in the atmosphere, and the density of the blank is 5.4g / cm 3 ;

[0030] (4) Put the NdFeB blank obtained in step (3) into a vacuum tube furnace, the vacuum degree in the furnace is 0.005 Pa before heating up, heat treatment at 1040° C. for 1 hour, and obtain a magnet.

Embodiment 2

[0032] (1) The cleaned raw materials are mechanically crushed under nitrogen protection, passed through a 60-mesh sieve, and the powder under the sieve is raw material magnetic powder;

[0033] (2) Combine 90g of the raw material magnetic powder obtained in step (1) with 10g of commercially available Dy with a particle size of less than 2500 mesh 2 o 3 The diffusing agent powder is added into the mixer and mixed for 2 hours to obtain mixed magnetic powder;

[0034] (3) Orientate and press the mixed magnetic powder obtained in step (2) in the atmosphere, and the density of the blank is 5.0g / cm 3 ;

[0035] (4) Put the NdFeB blank obtained in step (3) into a vacuum tube furnace, the vacuum degree in the furnace is 0.005Pa before heating up, heat treatment at 1000°C for 1 hour, and obtain a magnet.

Embodiment 3

[0037] (1) The cleaned raw materials are mechanically crushed under nitrogen protection, passed through a 60-mesh sieve, and the powder under the sieve is raw material magnetic powder;

[0038] (2) mix 90g of the raw material magnetic powder obtained in step (1) with 10g of 100 mesh Nd 2 Al diffuser powder is added into the mixer and mixed for 1 hour to obtain mixed magnetic powder;

[0039] (3) Orientate and press the mixed magnetic powder obtained in step (2) in the atmosphere, and the density of the blank is 5.2g / cm 3 ;

[0040] (4) Put the NdFeB blank obtained in step (3) into a vacuum tube furnace, the vacuum degree in the furnace is 0.005 Pa before heating up, heat treatment at 1040° C. for 1 hour, and obtain a magnet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com