Emulsion

An emulsion technology, which is used in textiles, papermaking, fiber processing, etc., can solve the problems of dust explosion, casualties, property losses, etc., and achieve the effect of improving yarn production rate, good cohesion, and fluffy and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

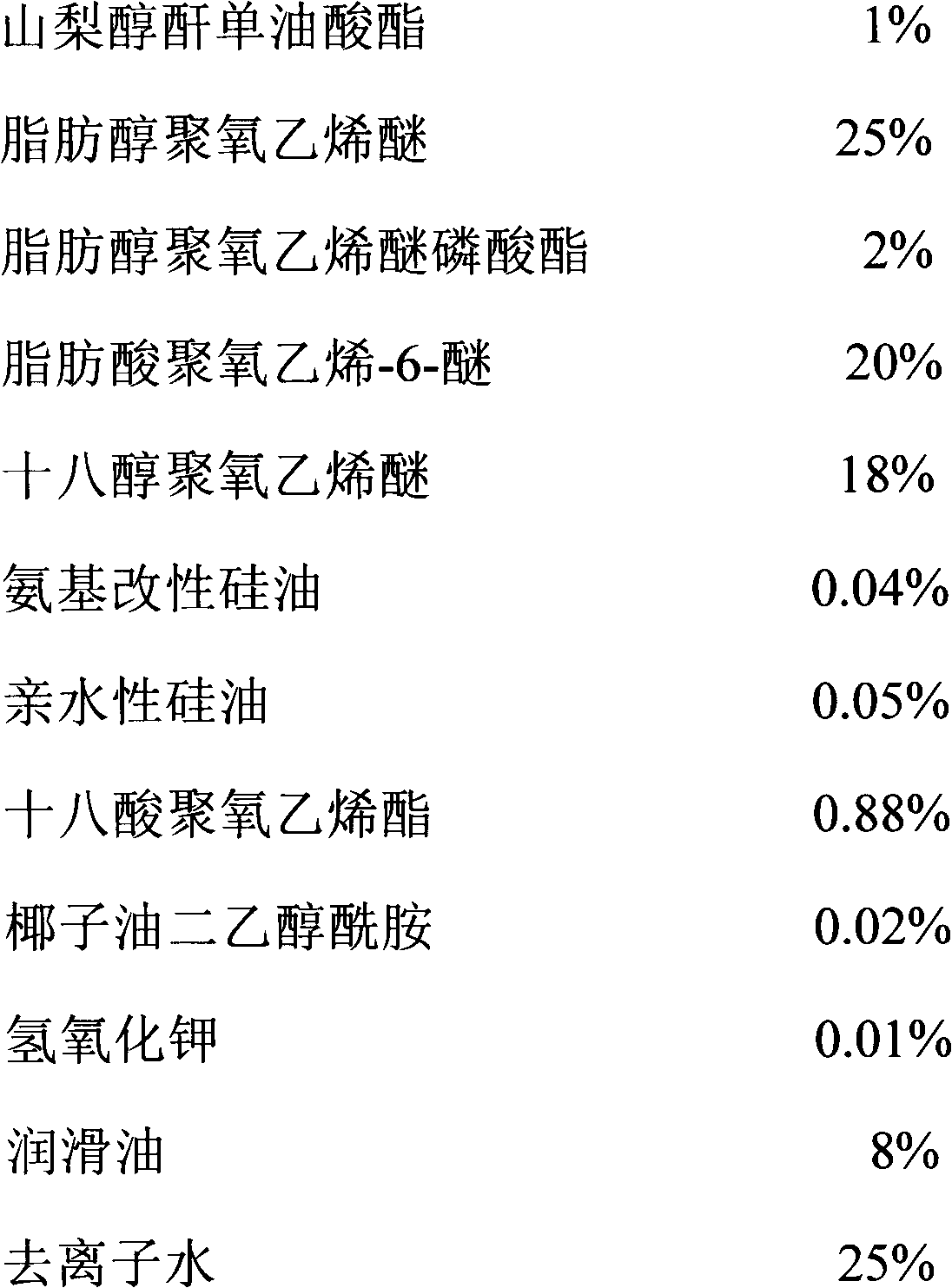

[0015] Determine the ratio of each component by mass percentage:

[0016]

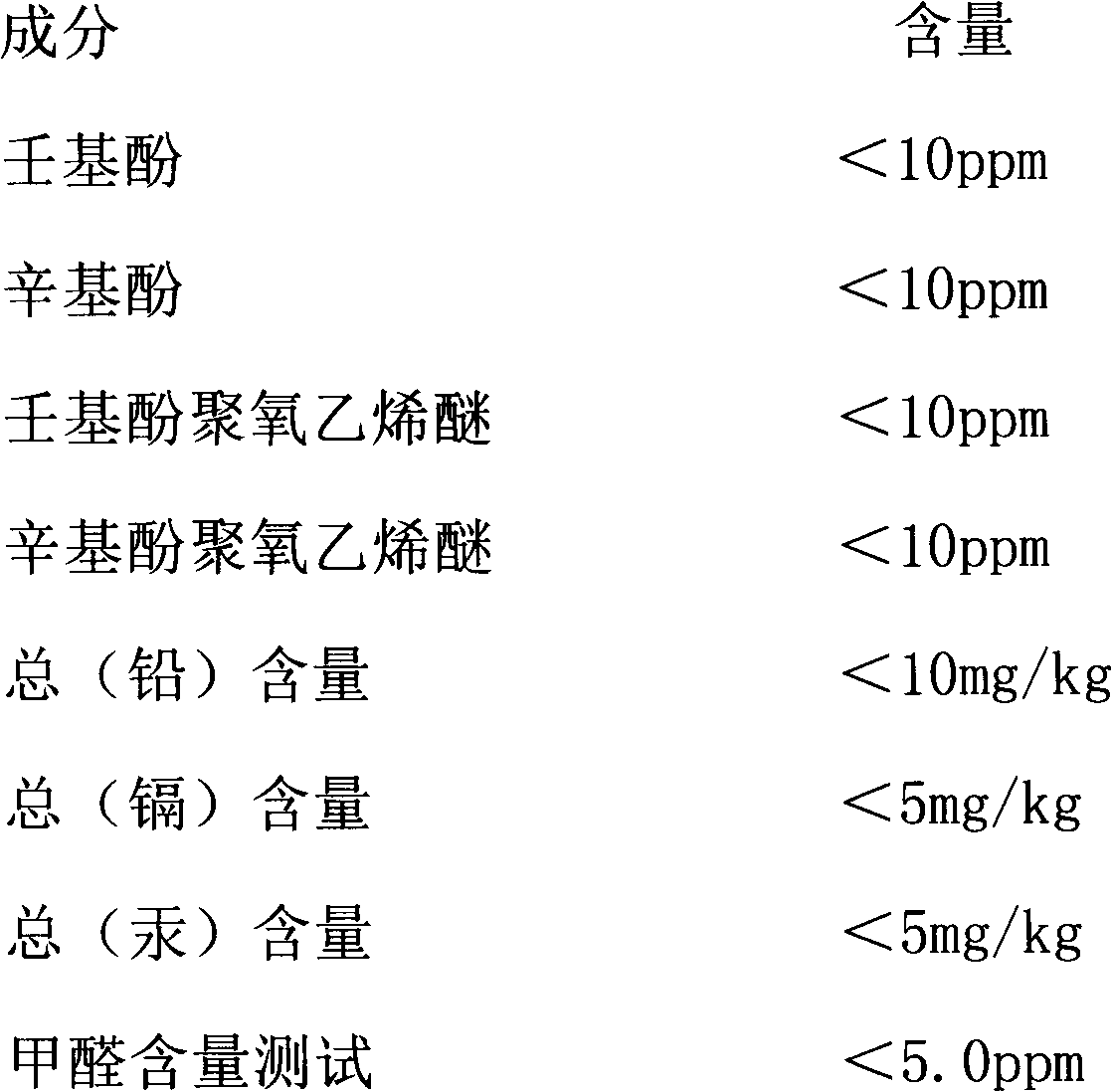

[0017] The emulsion prepared according to the above ratio is used in the spinning process, which can significantly reduce the "flying" phenomenon in the spinning process, reduce the electrostatic influence between the yarn and the drum during the spinning process, and make the yarn dry and uniform, and the hairiness is smooth , to promote smooth spinning, and significantly increase the yield of yarn; yarn strength after yarn is high, feel fluffy, soft and elastic; the emulsion is easy to wash in the subsequent section, which is helpful for subsequent dyeing, The processes of rinsing and shrinking are carried out smoothly. After the inspection of Intertek, the data is as follows:

[0018]

[0019] It can be seen from the above data that it meets the export requirements of Europe and the United States.

Embodiment 2

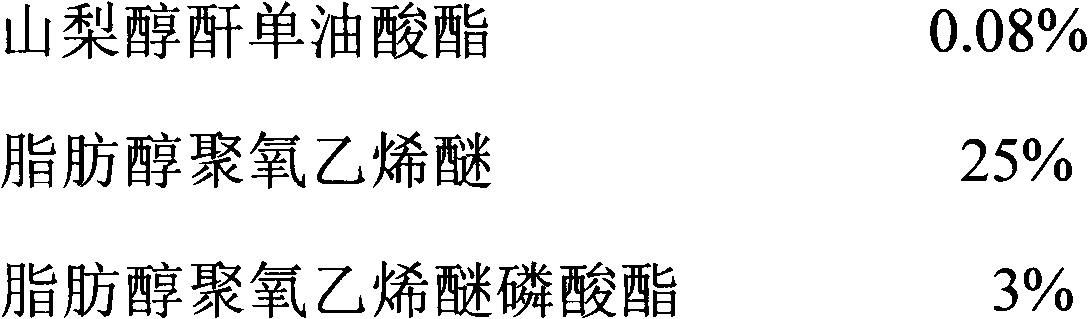

[0021] According to the following mass percentages, determine the ratio of each component:

[0022]

[0023]

[0024] The emulsion prepared according to the above ratio is used in the spinning process, which can significantly reduce the "flying" phenomenon in the spinning process, reduce the electrostatic influence between the yarn and the drum during the spinning process, and make the yarn dry and uniform, and the hairiness is smooth , to promote smooth spinning, and significantly increase the yield of yarn; yarn strength after yarn is high, feel fluffy, soft and elastic; the emulsion is easy to wash in the subsequent section, which is helpful for subsequent dyeing, The processes of rinsing and shrinking are carried out smoothly. After the inspection of Intertek, the data is as follows:

[0025]

[0026]

[0027] It can be seen from the above data that it meets the export requirements of Europe and the United States.

Embodiment 3

[0029] According to the following mass percentages, determine the ratio of each component:

[0030]

[0031] The emulsion prepared according to the above ratio is used in the spinning process, which can significantly reduce the "flying" phenomenon in the spinning process, reduce the electrostatic influence between the yarn and the drum during the spinning process, and make the yarn dry and uniform, and the hairiness is smooth , to promote smooth spinning, and significantly increase the yield of yarn; yarn strength after yarn is high, feel fluffy, soft and elastic; the emulsion is easy to wash in the subsequent section, which is helpful for subsequent dyeing, The processes of rinsing and shrinking are carried out smoothly. After the inspection of Intertek, the data is as follows:

[0032]

[0033] It can be seen from the above data that it meets the export requirements of Europe and the United States.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com