Full-glazed tile and preparation method thereof

A technology of full glaze and bottom glaze, applied in the field of ceramic building materials, can solve the problem of low whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

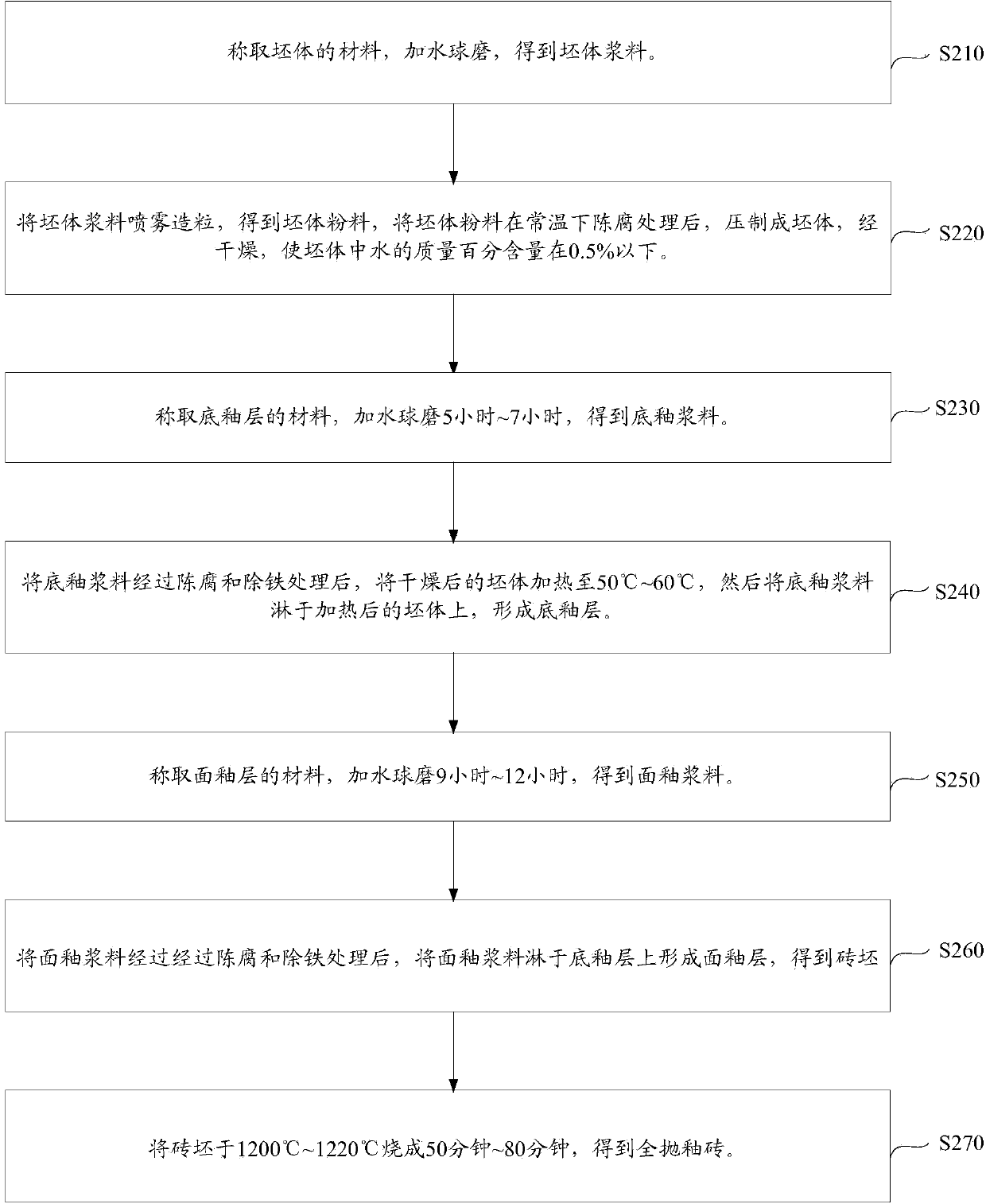

[0035] Such as figure 2 As shown, a method for preparing a fully polished glazed tile in an embodiment includes the following steps:

[0036] Step S210: Weigh the material of the green body and add water ball milling to obtain the green body slurry. Among them, the material of the body includes the following raw materials by mass percentage: clay 18% to 32%, feldspar 30% to 50%, quartz 20% to 40%, talc 2% to 3% and sodium tripolyphosphate 0.3% ~0.5%. The fineness of the green body slurry is 0.7% to 0.9% after the 250 mesh sieve, and the mass percentage of water in the green body slurry is 32% to 34%.

[0037] Before weighing each raw material in the material of the green body, each raw material needs to be homogenized and piled up stale to stabilize the composition of the raw material and ensure the accuracy of the formula.

[0038] The fineness of the green slurry is 0.7% to 0.9% after the 250 mesh screen, which can make the whiteness of the polished tiles more uniform and the t...

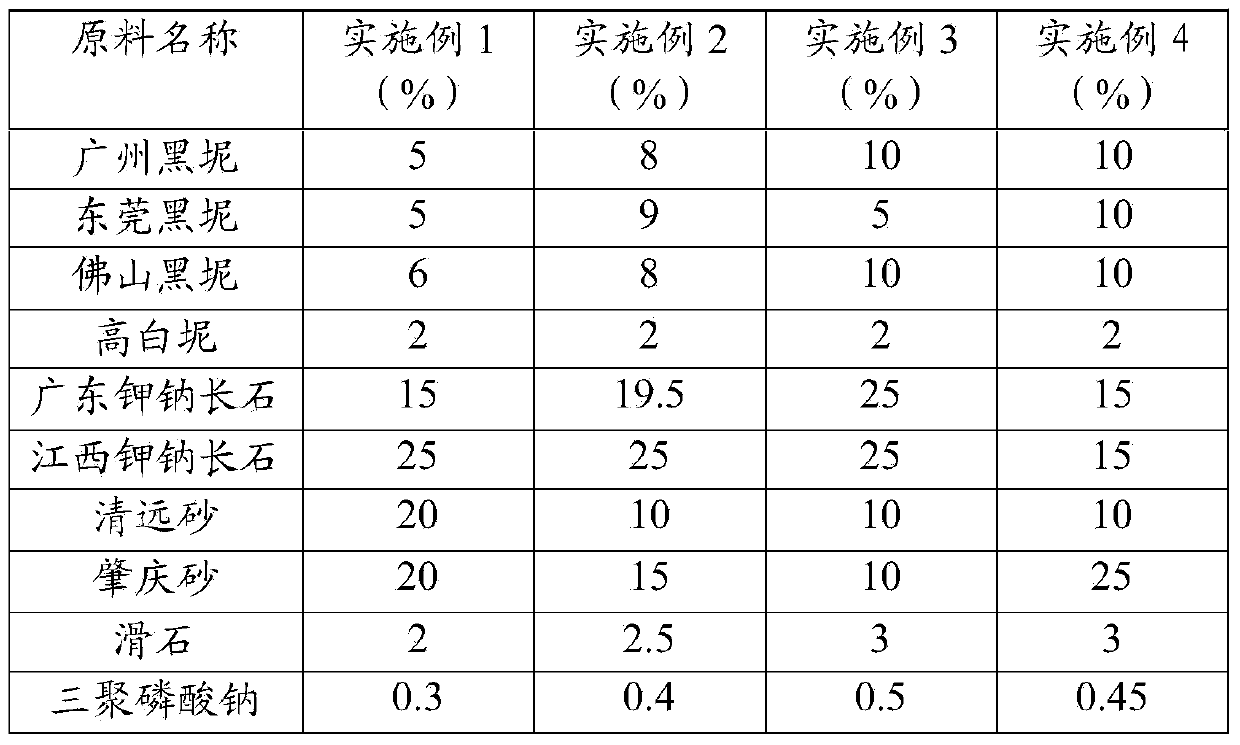

Embodiment 1

[0075] The preparation of the fully polished glazed tile of this embodiment is as follows:

[0076] (1) Homogenize the raw materials in Table 1, Table 2 and Table 3 with an excavator or forklift, and after stacking them stale, weigh the green body materials according to Table 1, and add water to ball mill for 16 hours to obtain green body slurry. Among them, the fineness of the green slurry is 0.7% with a 250 mesh screen, and the mass percentage of water in the green slurry is 32%. The flow rate of the green slurry measured with a Tu-4 viscometer was 40 seconds.

[0077] (2) The green slurry is sprayed and granulated in a spray tower to obtain green powder, wherein the water mass percentage of the green powder is 6.3%, and the particle size is: 40 mesh to 80 mesh. 80%, 2.9% of particles under 100 mesh. The bulk density of the body powder is 0.93 g / ml. After the green body powder is aged at room temperature for 24 hours, it is pressed into a green body by a fully automatic hydrau...

Embodiment 2

[0086] The preparation of the fully polished glazed tile of this embodiment is as follows:

[0087] (1) Homogenize the raw materials in Table 1, Table 2 and Table 3 with an excavator or forklift, and after stacking them stale, weigh the green body materials according to Table 1, and add water to ball mill for 18 hours to obtain green body slurry. Among them, the fineness of the green slurry is 0.9% with a 250 mesh screen, and the mass percentage of water in the green slurry is 34%. The flow rate of the green slurry measured with a Tu-4 viscometer was 50 seconds.

[0088] (2) The green slurry is sprayed and granulated in a spray tower to obtain green powder, wherein the water mass percentage of the green powder is 7.2%, and the particle gradation is: 40 mesh to 80 mesh. 90%, 2% of particles under 100 mesh. The bulk density of the body powder is 1 g / ml. After the green body powder is aged at room temperature for 30 hours, it is pressed into a green body using a fully automatic hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com