Wellbore composite plug assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

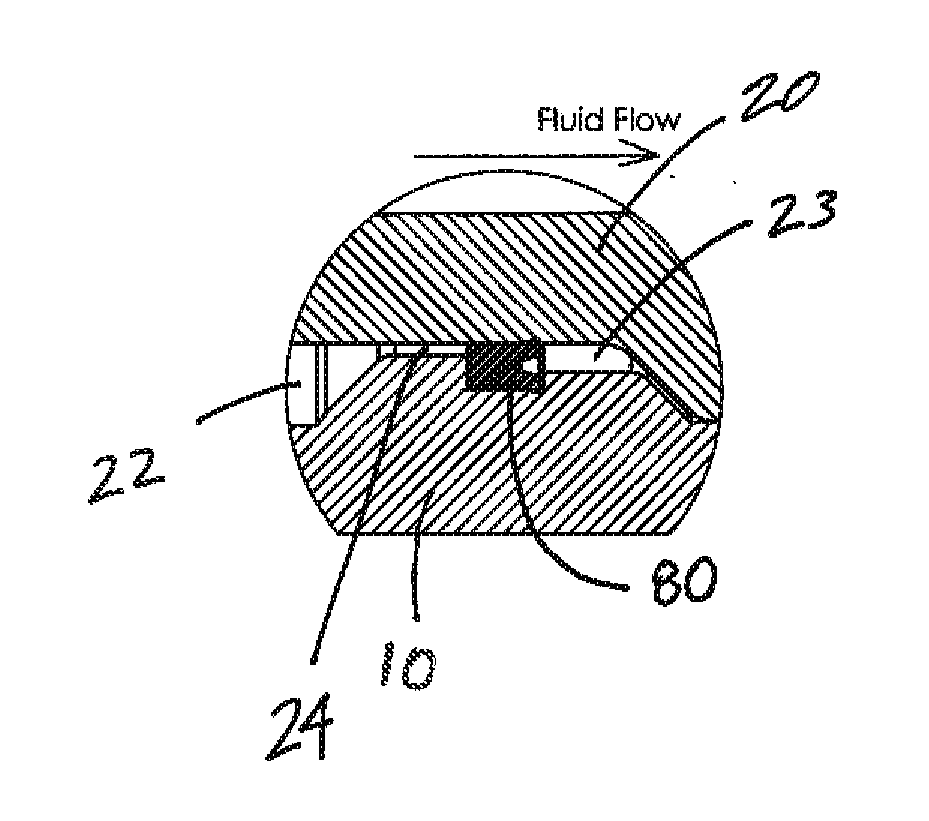

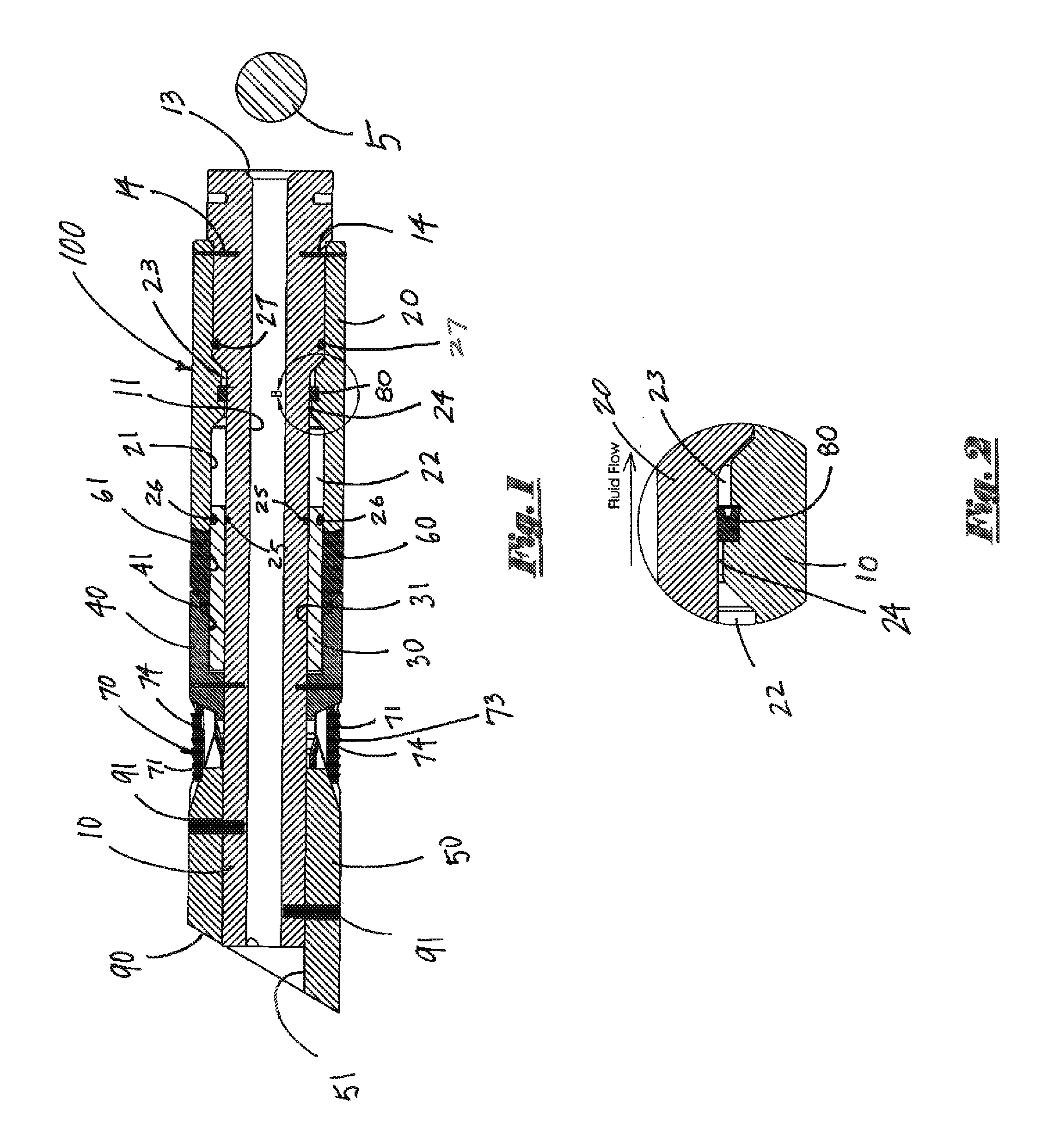

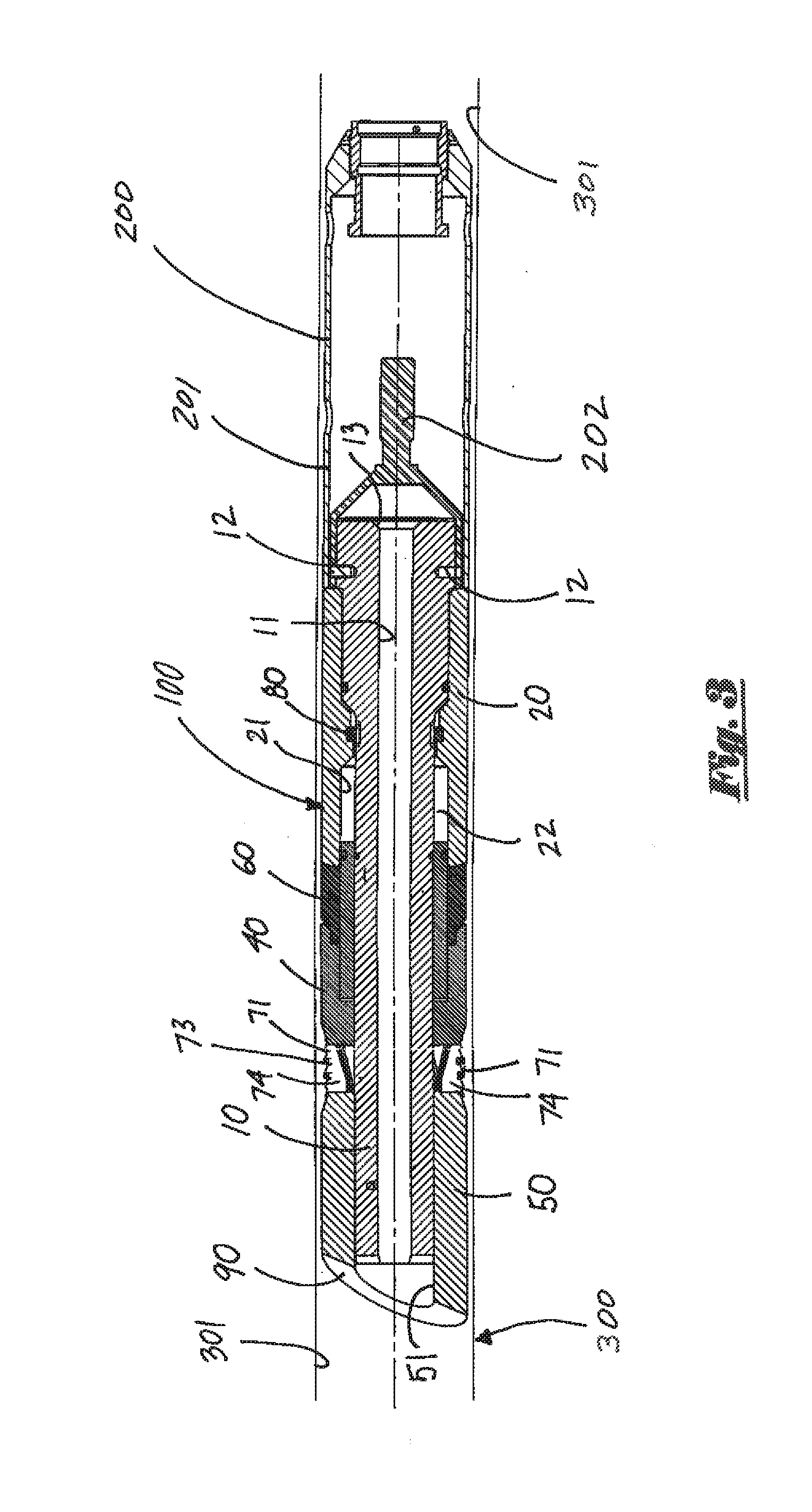

[0032]The present invention comprises a plug assembly for down hole use in wellbores such as, for example, in oil or gas wells that penetrate subterranean formations. In a preferred embodiment, certain components of the plug assembly of the present invention can be beneficially manufactured from at least one material that can be relatively quickly and efficiently milled, drilled or otherwise mechanically broken apart such as, for example, composite resin impregnated fiber or other material exhibiting similar characteristics.

[0033]The plug assembly of the present invention can be installed to selectively isolate one portion of a wellbore from another, to prevent fluid flow from one portion of a wellbore to another and / or to provide a fluid pressure sealing barrier at a desired location within a wellbore. The plug assembly of the present invention can be beneficially set within the internal bore of a string of casing, production tubing or other tubular. However, it is to be observed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com