5182-O state aluminum alloy plate for automobile inner plate and production method for 5182-O state aluminum alloy plate

An aluminum alloy sheet and production method technology, applied in metal rolling and other directions, can solve the problems of easy occurrence of orange peel defects, poor surface quality, uniform grain size and limited fineness, etc., and achieves fast heating speed, uniform temperature, surface Even and delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

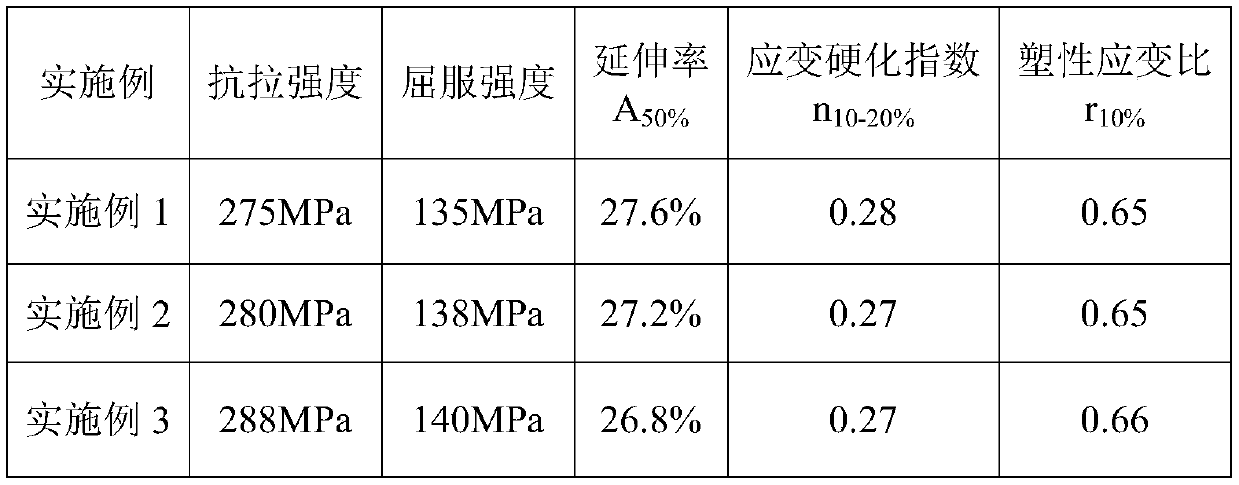

Examples

Embodiment 1

[0034] A kind of production method of 5182-O state aluminum alloy sheet material for automobile interior plate, comprises the following steps:

[0035] Step 1: Ingredients:

[0036] Raw materials are prepared according to the following weight percentages: Si 0.128%, Fe 0.174%, Cu 0.013%, Mn 0.247%, Mg 4.570%, Cr 0.037%, Zn 0.025%, Ti 0.024%, and the balance is Al.

[0037] Step 2: Melting and Casting:

[0038] The mixed metals are smelted at 700°C to 750°C for 5 to 8 hours, and the standing refining is carried out as usual, except

[0039] Gas, add grain refiner Al-5Ti-1B wire, filter, and measure the hydrogen content in the launder ≤0.12mL / 100gAL; then cast at 700℃~730℃ by semi-continuous casting method, casting speed 45~55mm / min, the size of the ingot depends on the actual width of the product.

[0040] Step 3: Homogenizing heat treatment:

[0041] The ingot is subjected to a homogenization heat treatment at 500°C to 520°C for a holding time of 12 to 14 hours. After cooli...

Embodiment 2

[0054] A kind of production method of 5182-O state aluminum alloy sheet material for automobile interior plate, comprises the following steps:

[0055] Step 1: Ingredients:

[0056] Raw materials are prepared according to the following weight percentages: Si 0.120%, Fe 0.205%, Cu 0.015%, Mn 0.252%, Mg 4.623%, Cr 0.038%, Zn 0.023%, Ti 0.027%, and the balance is Al.

[0057] Step 2: Melting and Casting:

[0058] Smelting the mixed metal at 700°C-750°C for 5-8 hours, standing and refining as usual, degassing, adding grain refiner Al-5Ti-1B wire, filtering, and measuring the hydrogen content in the launder ≤0.12mL / 100gAL; then casting at 700℃~730℃ by semi-continuous casting method, the casting speed is 45~55mm / min, and the ingot size is determined according to the actual width of the product.

[0059] Step 3: Homogenizing heat treatment:

[0060] The ingot is subjected to a homogenization heat treatment at 500°C to 520°C for a holding time of 12 to 14 hours. After cooling, it ...

Embodiment 3

[0072] Raw materials are prepared according to the following weight percentages: Si 0.142%, Fe 0.252%, Cu 0.015%, Mn 0.272%, Mg 4.831%, Cr 0.042%, Zn 0.024%, Ti 0.031%, and the balance is Al.

[0073] Step 2: Melting and Casting:

[0074] The mixed metals are smelted at 700°C to 750°C for 5 to 8 hours, and the standing refining is carried out as usual, except

[0075] Gas, add grain refiner Al-5Ti-1B wire, filter, and measure the hydrogen content in the launder ≤0.12mL / 100gAL; then cast at 700℃~730℃ by semi-continuous casting method, casting speed 45~55mm / min, the size of the ingot depends on the actual width of the product.

[0076] Step 3: Homogenizing heat treatment:

[0077] The ingot is subjected to a homogenization heat treatment at 500°C to 520°C for a holding time of 12 to 14 hours. After cooling, it is machined, and the head and tail are cut and face milled.

[0078] Step 4: Hot rolling:

[0079] Heat the ingot to 480°C-510°C, keep it warm for more than 3 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com