Continuous annealing furnace

A continuous annealing furnace and furnace body technology, applied in furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of grain growth, stains, uneven grains, etc., and achieve fine and uniform metal crystal structure, rapid heating and Uniform, uniform annealing temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

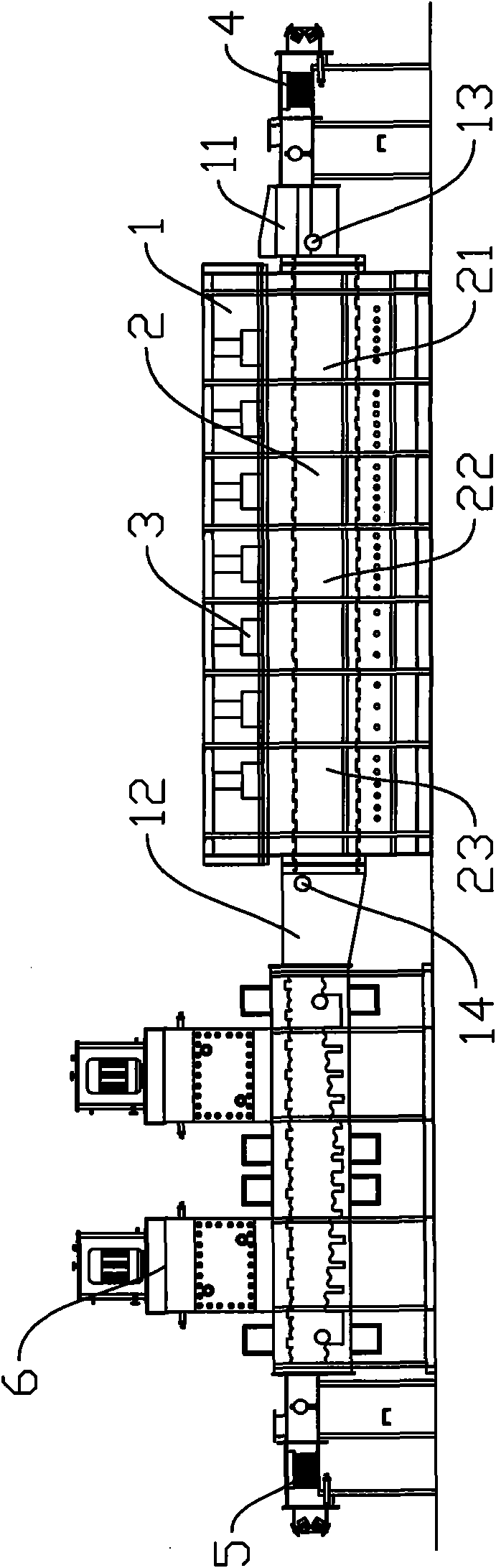

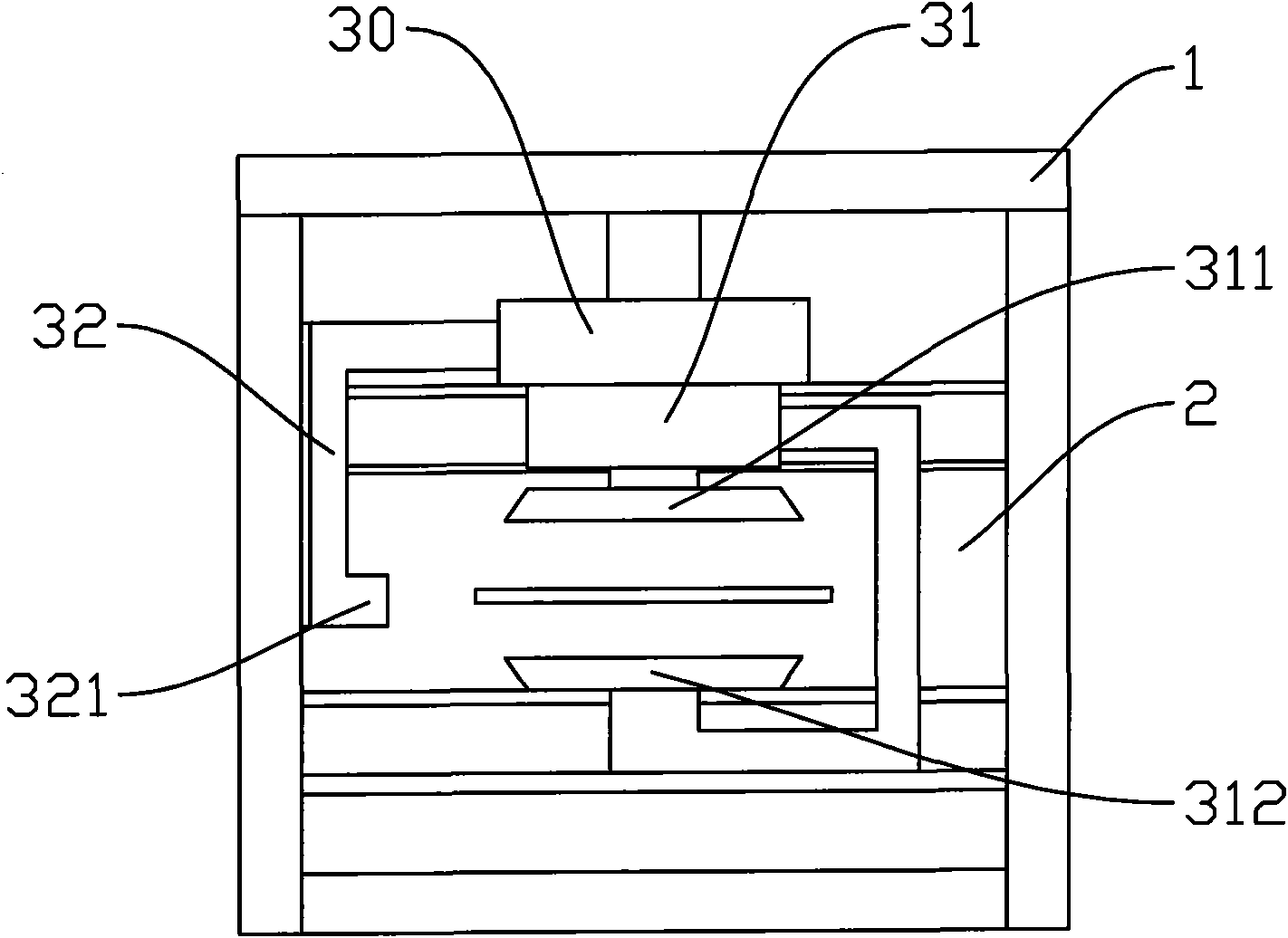

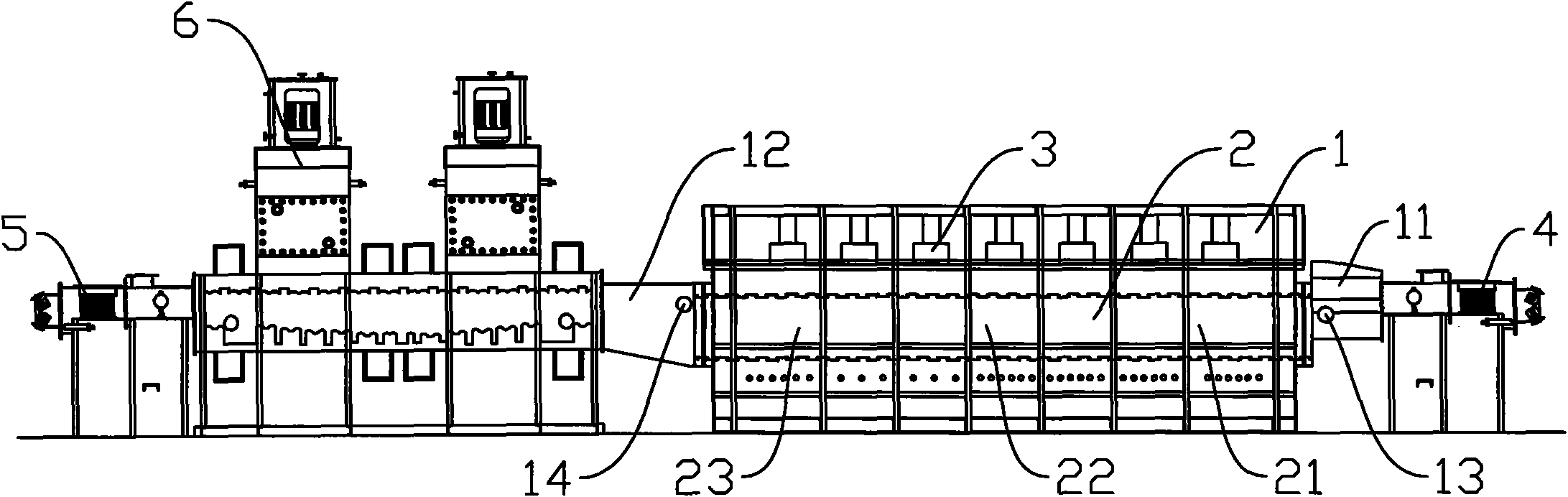

[0021] Such as figure 1 with 2 Shown is a schematic structural view of an embodiment of the present invention, a continuous annealing furnace, comprising a furnace body 1, a feed inlet 11 is provided at the front end of the furnace body, and a discharge port 12 is provided at the rear end of the furnace body. There is a furnace 2 for heating the strip, and the furnace is filled with a protective atmosphere during operation. The front end of the furnace is provided with a tension roller I13, and the rear end of the furnace is provided with a tension roller II14. The hot section 21, the heating section 22 and the cooling section 23. The cooling section is provided with an air supply pipe connected to the suction pipe of the fan on the preheating section. The fan sucks the hot air emitted by the annealed strip through the air supply pipe and sends it to the preheating section. The unannealed strip is preheated in the section. The furnace body is provided with a circulation fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com