Aluminum-made vertical heat sink device with high temperature distribution uniformity

A temperature distribution and uniformity technology, applied in the aerospace field, can solve problems such as large size, complex structure, and limited installation methods, and achieve the effect of convenient operation, common materials, and good temperature distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

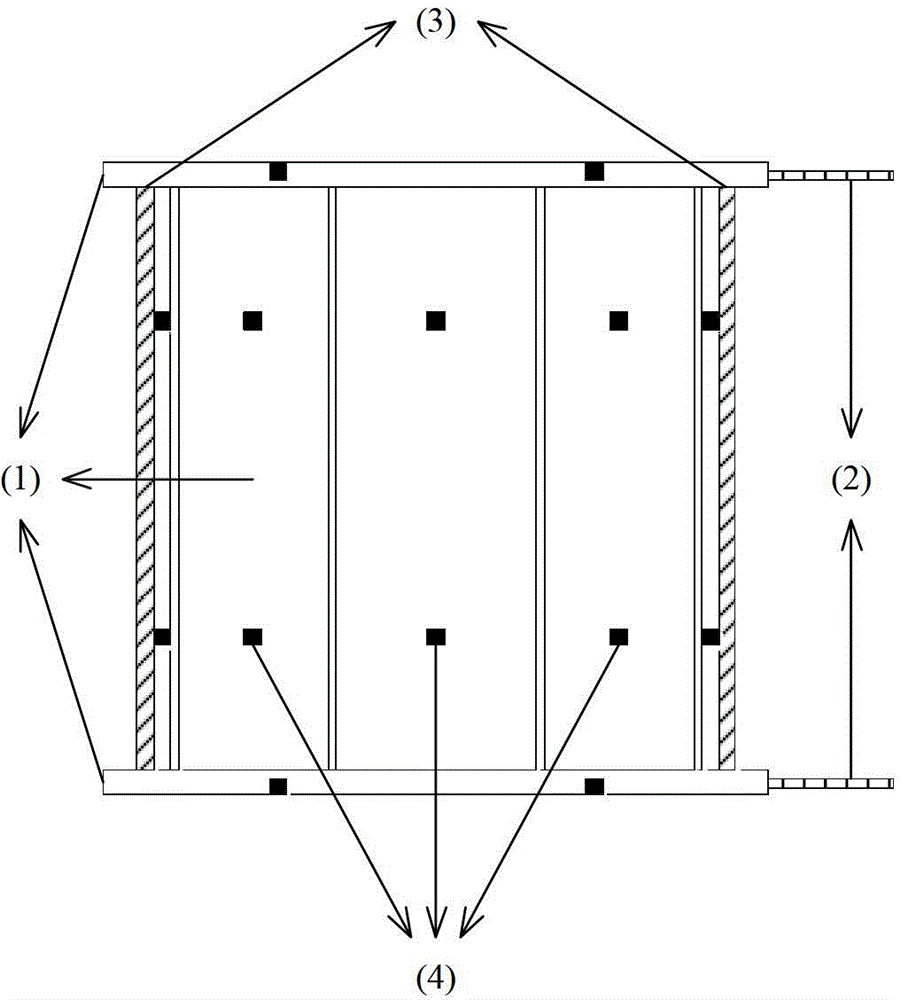

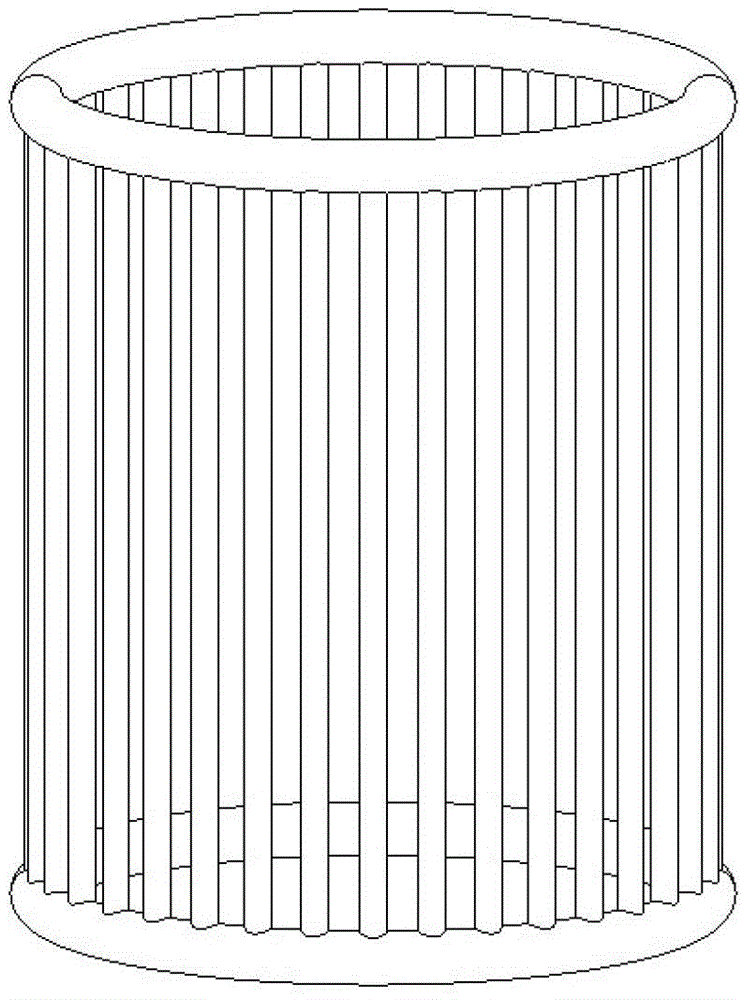

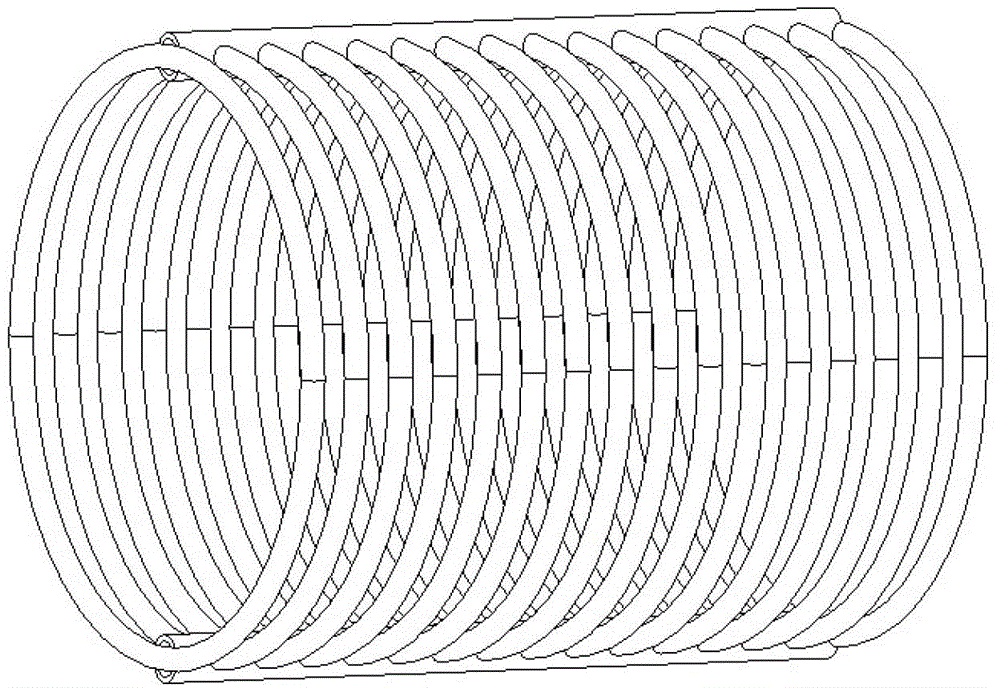

[0045] Such as figure 1 As shown, the present invention is an aluminum vertical heat sink device with relatively high temperature distribution uniformity applied to micro-satellite space environment simulation tests. The heat sink device consists of a finned tube array surface (1), a metal corrugated soft Tube (2), multi-layer insulation material (3) and temperature acquisition system (4). The position connection relationship between them is: eight 460mm x 1160mm finned tube array surfaces (1) form the sides of an octagonal prism; two 1120mm x 1200mm finned tube array surfaces (1) are the top of the heat sink device surface and bottom surface; metal corrugated hose (2) connects each surface to make the inner cavity of the whole heat sink device integrated; the thermistor in the temperature acquisition system (4) is attached to the outer surface of the heat sink device; multi-layer heat insulation material ( 3) is coated on the outermost part of the device.

[0046] The finne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com