Friction surface microstructure scratch-resistant brake disc body

A friction surface, microstructure technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problems of large deformation in the middle area of the bolt hole, small deformation of the bolt hole, easy to wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

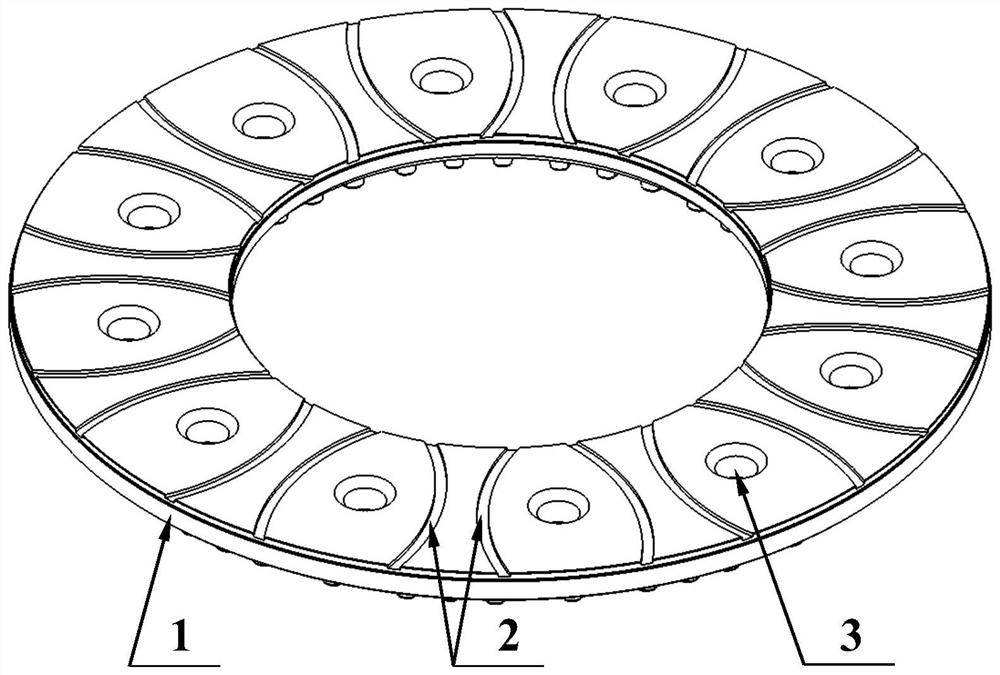

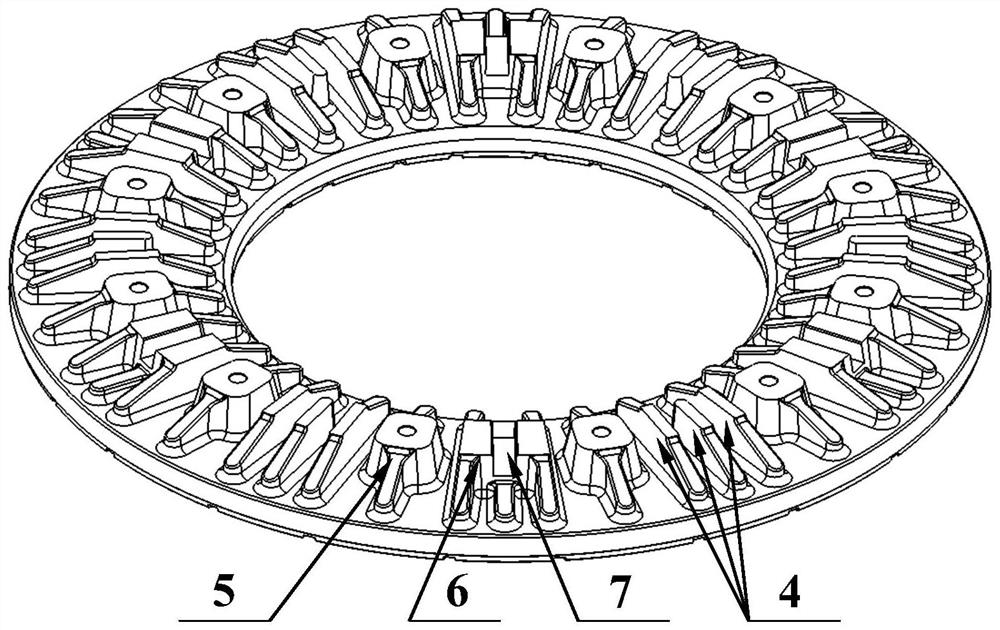

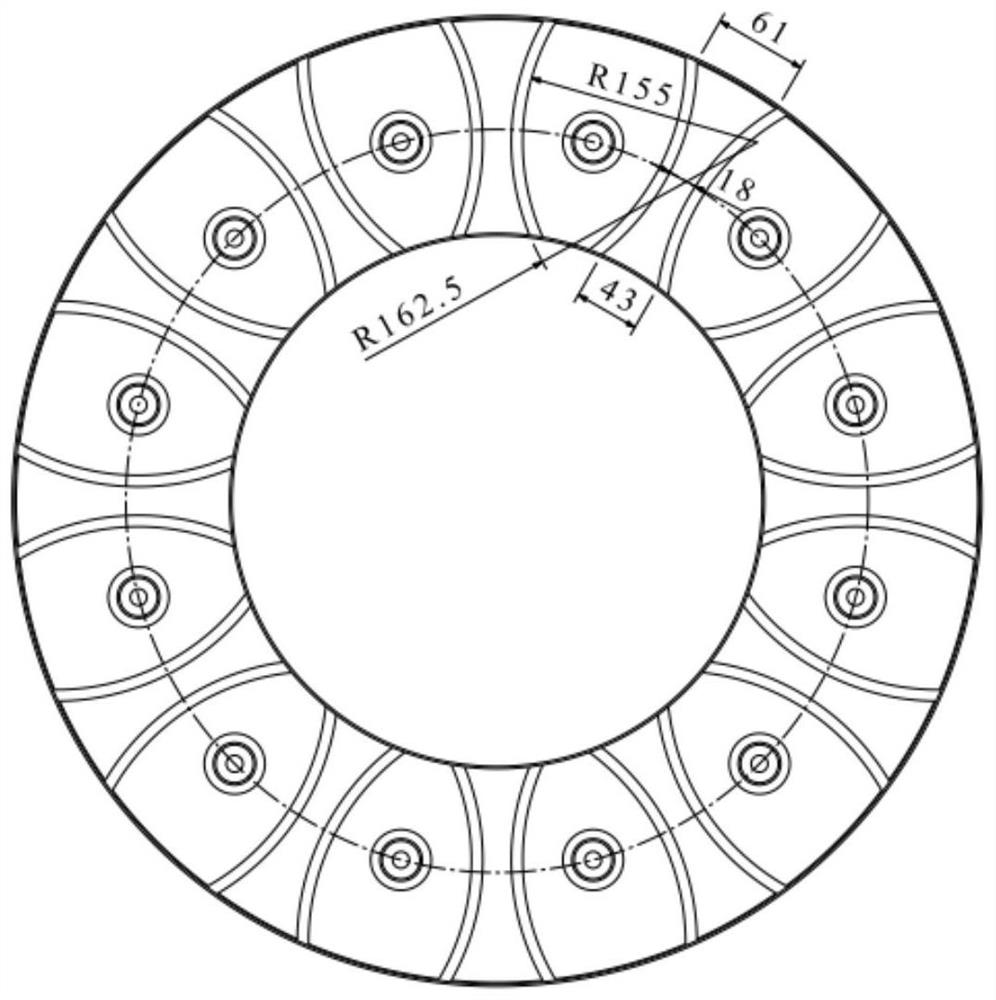

[0025] like Figure 1 to Figure 5 As shown in the figure, the friction surface microstructure of the present invention resists the scratching of the aluminum alloy brake disc body, including: a friction ring 1, the friction ring 1 is evenly distributed with bolt holes 3 (bolt holes 3 are stepped bolt holes) along the circumferential direction, and the friction ring The outer surface of the 1 is provided with a number of chip removal and resistance scribe grooves 2 that pass through. The inner side of the friction ring 1 is provided with a heat dissipation rib group 4, a connection boss 5 and a positioning assembly 6, and a positioning groove 7 is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com