Clamp and process used for coating inner bore with diamond film

A diamond film and coating technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, to achieve the effect of reducing production cost, automatically compensating for hot wire drawing and excellent heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

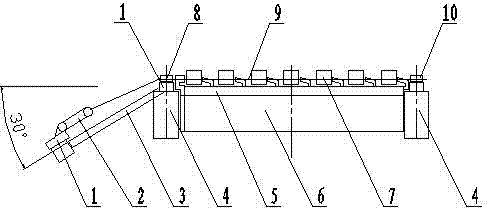

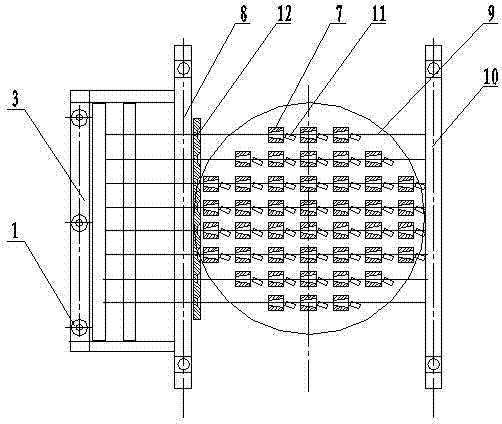

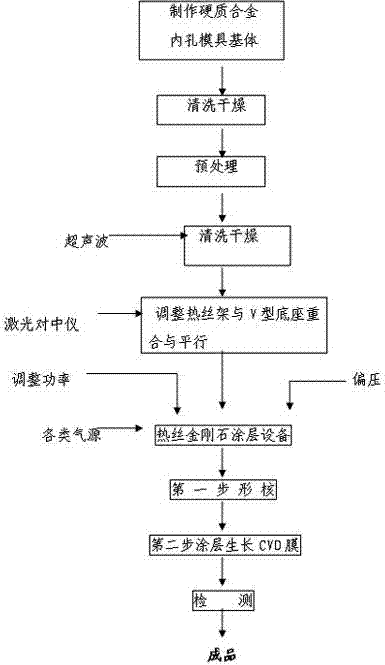

Method used

Image

Examples

Embodiment 1

[0035] Take 60 pieces of inner hole Ф5mm wire drawing die (referred to as "workpiece") inner hole coating diamond film as an example:

[0036]1. Use absolute alcohol to clean and remove the anti-rust oil on the surface of the workpiece, then put the cleaned workpiece into a constant temperature drying box, dry it within 1 minute, and control the temperature at 50°C;

[0037] 2. Use the pretreatment solution to etch the surface of the substrate in an ultrasonic cleaning machine to perform "pretreatment" for 50 minutes, and then dry it to increase the nucleation density of the diamond film deposition. The pretreatment solution is: use sodium ferrate (Na 2 FeO 4 ), potassium hydroxide (KOH), water (H 4 o 2 ) is prepared according to the weight ratio of 1:2:20;

[0038] 3. Then use W6 diamond micropowder to polish the workpiece pretreated in the previous step, so that the workpiece forms a frame foundation before coating the diamond film;

[0039] 4. Clean again: use acetone +...

Embodiment 2

[0047] Taking 40 pieces of drawing dies with Ф10mm inner holes (referred to as "workpieces"), the equipment in Example 1 and the diamond film in the inner hole of the jig to calibrate the center line of the V-shaped pad as an example:

[0048] Use absolute alcohol to clean and remove the anti-rust oil on the surface of the workpiece, then put the cleaned workpiece into a constant temperature drying oven, dry it within 1 minute, and control the temperature at 60°C;

[0049] Next, use a pretreatment solution to etch the surface of the substrate in an ultrasonic cleaner for 50 minutes of "pretreatment" and dry it to increase the nucleation density of the diamond film deposition. The pretreatment solution is: use sodium ferrate (Na 2 FeO 4 ), potassium hydroxide (KOH), water (H 4 o 2 ) is prepared according to the weight ratio of 1:2:20;

[0050] Then use W6 diamond micropowder to polish the workpiece pretreated in the previous step, so that the workpiece forms a frame foundati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com