Heater based on silver nanowire transparent conductive film and preparation method thereof

A technology of transparent conductive film and silver nanowires, which is applied in the direction of transparent/reflective heating devices, ohmic resistance heating, electric heating devices, etc., can solve the problems of transparent heaters such as complex process, easy corrosion, uneven heating, etc., and achieve uniform temperature distribution Sexuality, good for scale, and good for power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

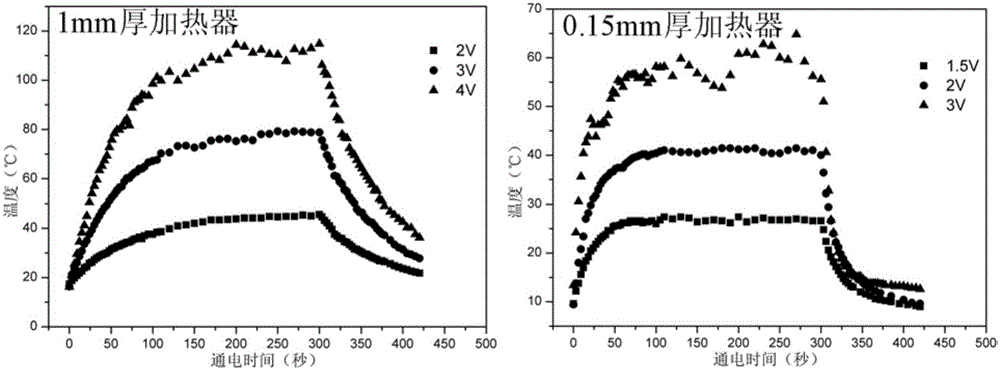

[0040] This embodiment provides a 1mm thick glass heater based on a silver nanowire transparent conductive film and a preparation method thereof, and uses the heater as a defogging glass, the steps are as follows:

[0041](1) Hydrophilic treatment of glass substrates: Ultrasonic cleaning of glass with a size of 50 mm × 60 mm and a thickness of 1 mm in acetone, ethanol, and deionized water for 30 minutes, after drying, put it into an ultraviolet ozone cleaning machine, and treat it at 60 ° C for 20 minutes. minutes to make the surface hydrophilic.

[0042] (2) Preparation of transparent conductive film: the silver nanowires synthesized by the polyol method were ultrasonically dispersed in a mixture of ethanol and isopropanol (volume ratio 1:1) at a concentration of 10 mg / mL. Take 1mL of the dispersion and add it dropwise on the glass with a hydrophilic surface. Use a spatula to evenly coat the liquid on the glass surface. The distance between the spatula and the glass is 50 μm....

Embodiment 2

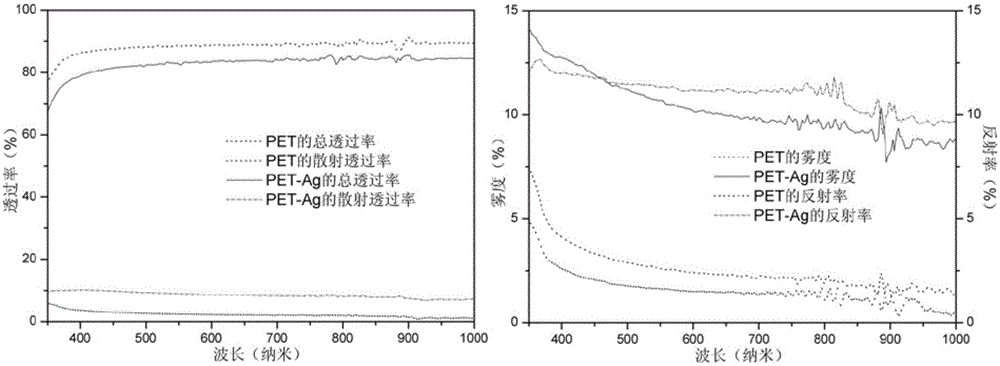

[0047] This embodiment provides a 0.2 mm thick PET heater based on a silver nanowire transparent conductive film and a preparation method thereof, and uses the heater as a thermochromic substrate, the steps are as follows:

[0048] (1) Hydrophilic treatment of PET substrate: Ultrasonic cleaning of PET with a size of 50mm×60mm and a thickness of 0.2mm in acetone, ethanol, and deionized water for 30 minutes, after drying, put it into a UV-ozone cleaning machine, and treat it at 60°C 20 minutes to make the surface hydrophilic.

[0049] (2) Preparation of transparent conductive film: the silver nanowires synthesized by the polyol method were ultrasonically dispersed in a mixture of ethanol and isopropanol (volume ratio 1:1) at a concentration of 10 mg / mL. Take 1mL of the dispersion liquid and add it dropwise on the PET with hydrophilic surface, use a scraper to evenly coat the liquid on the PET surface, the distance between the scraper and PET is 50μm, repeat this step after dryin...

Embodiment 3

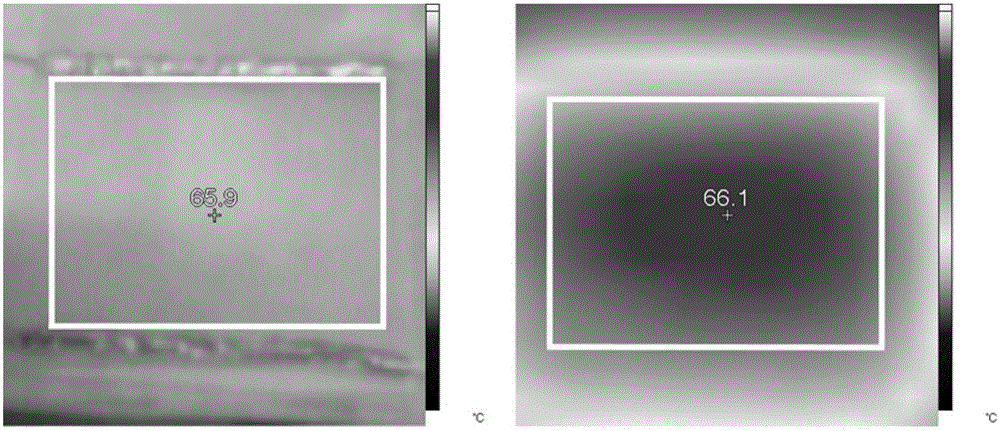

[0054] This embodiment provides a 0.15 mm thick glass heater based on a silver nanowire transparent conductive film and a preparation method thereof, and uses the heater as a fast thermal response substrate, and the steps are as follows:

[0055] (1) Hydrophilic treatment of glass substrate: Ultrasonic cleaning of glass with a size of 50 mm × 60 mm and a thickness of 0.15 mm in acetone, ethanol, and deionized water for 30 minutes, after drying, put it into an ultraviolet ozone cleaning machine, and treat it at 60 ° C 20 minutes to make the surface hydrophilic.

[0056] (2) Preparation of transparent conductive film: the silver nanowires synthesized by the polyol method were ultrasonically dispersed in a mixture of ethanol and isopropanol (volume ratio 1:1) at a concentration of 10 mg / mL. Take 1mL of the dispersion and add it dropwise on the glass with a hydrophilic surface. Use a spatula to evenly coat the liquid on the glass surface. The distance between the spatula and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com