Radial reactor for preparing ethylene (propylene) carbonate

A technology of reactor and carbonic acid, which is applied in the preparation of carbon dioxide or inorganic carbonate, organic chemistry, reagents, etc., can solve the problems of overheating of catalyst bed, increase of equipment investment, reduction of reaction conversion rate, etc., and achieve uniform distribution of radial temperature , Improve surface utilization and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

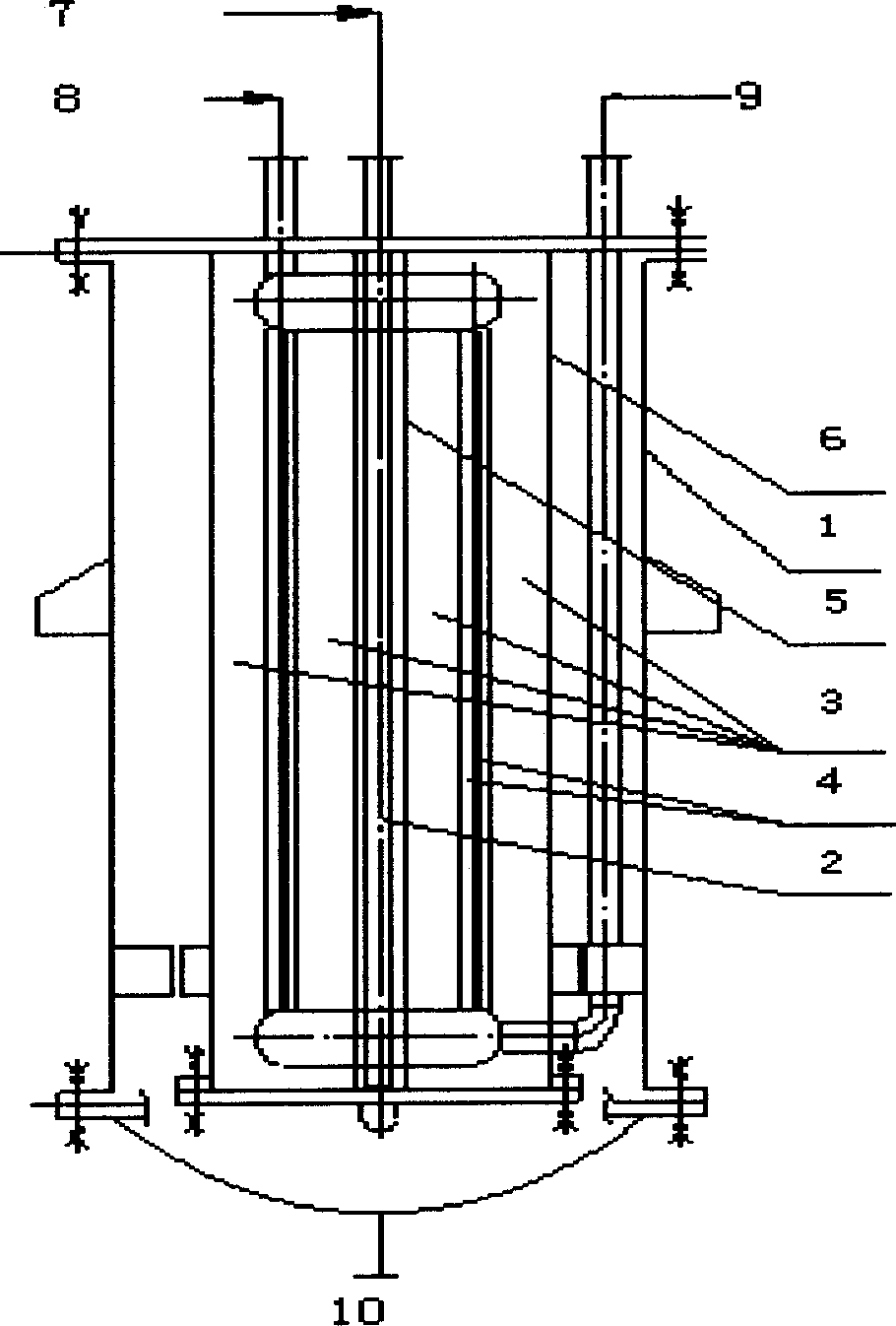

[0031] See accompanying drawing, use radial reactor of the present invention to prepare ethylene carbonate. Under a certain pressure, carbon dioxide and ethylene oxide enter the reactor 1 at a ratio of 20:1 to 80:1, and after being distributed through the holes on the feed pipe 2 in the center of the inner axis (feed pipe 2 wall The openings on the top are uniformly distributed wide-angle openings, the opening ratio is 1.15%), radially flow into the catalyst bed 3 along the concentric inner cylinder 5, flow out from the concentric outer cylinder 6 of the catalyst bed 3, and the inner cylinder 5 And the opening rate of the small holes on the outer cylinder 6 is 17%. Under the conditions of 110-125°C and 2.0-2.5MPa, the raw material carbon dioxide and ethylene oxide (propane) are reacted through the catalyst bed 3 to generate ethylene carbonate The product flows out from the outside of the annular catalyst bed layer 3 with distribution holes and flows to the lower outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com