Heat pump air conditioning system and vehicle

A heat pump air conditioner and water pump technology, applied in heat pumps, vehicle components, air handling equipment, etc., can solve problems such as increased cost, increased risk of refrigerant leakage, and many joints, and achieves compact layout, simplified control, and improved temperature uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1: Heating mode combined with heat pump and waste heat recovery.

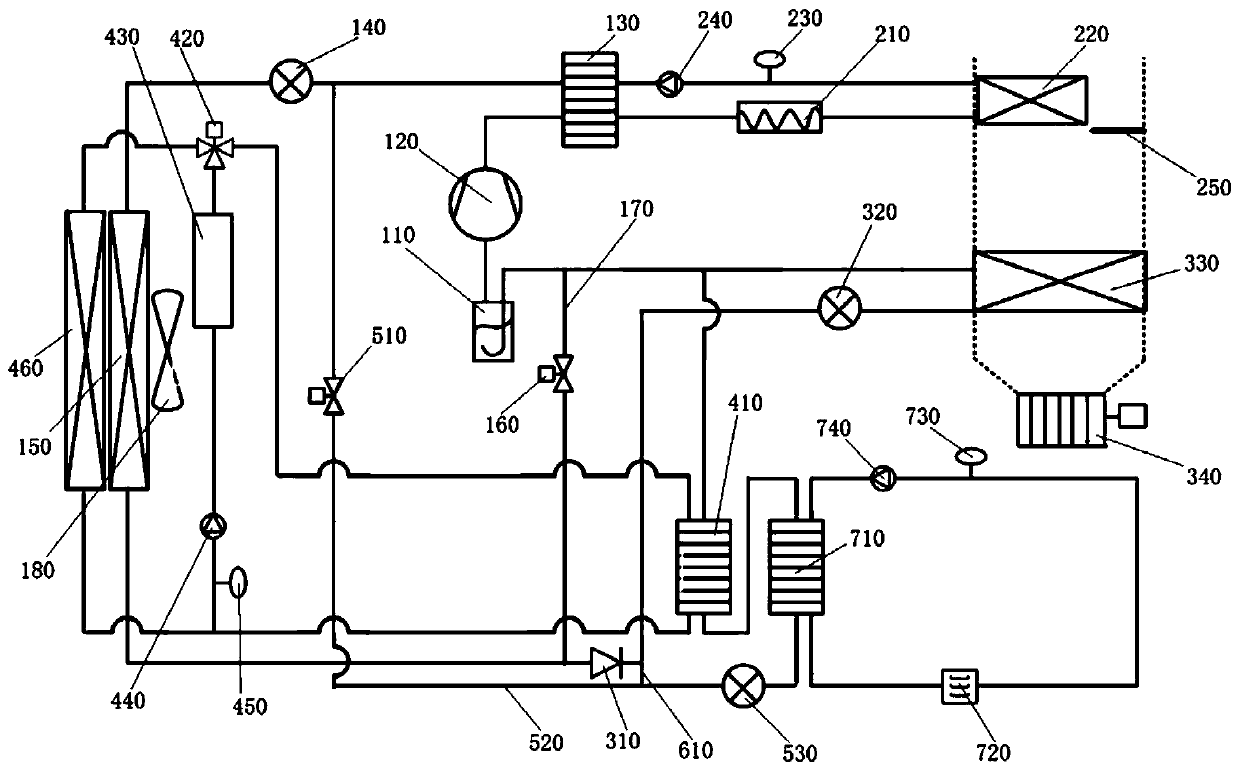

[0074]When the heat pump alone cannot meet the heat demand of the passenger compartment, the heat pump and waste heat recovery will be used in heating mode. The high-temperature and high-pressure refrigerant gas discharged from the electric compressor 120 flows to the third heat exchanger 130 , and the refrigerant liquid after being cooled and condensed in the third heat exchanger 130 is divided into two paths. All the way flows through the second expansion valve 140 for throttling to become a low-temperature and low-pressure two-phase refrigerant, then flows to the outdoor heat exchanger 150 to exchange heat with the external environment, and then passes through the second valve 160 to flow out from the third heat exchanger 130 The other path of liquid refrigerant passes through the first valve 510, the first expansion valve 530, and the second heat exchanger 710, enters the first heat exchan...

Embodiment 2

[0075] Embodiment 2: cooling mode.

[0076] In high temperature conditions, when the temperature of the passenger compartment needs to be cooled, the system activates the following operating modes.

[0077] The high-temperature and high-pressure refrigerant gas discharged from the electric compressor 120 passes through the third heat exchanger 130 and the second expansion valve 140 and then enters the outdoor heat exchanger 150 to release heat to the external environment to condense the internal refrigerant into a supercooled refrigerant. Pass through the check valve 310 and enter the third expansion valve 320 throttling to become a low-temperature low-pressure two-phase refrigerant, and then flow to the indoor evaporator 330 to cool the high-temperature air passing through the indoor evaporator 330, and use the blower to send the cooled air to the indoor evaporator 330. After entering the passenger compartment, the nearly saturated gaseous refrigerant flowing out from the ind...

Embodiment 3

[0078] Embodiment 3: battery cooling mode.

[0079] Under high-temperature conditions, when the vehicle needs to be fast-charged or the battery temperature rises rapidly due to other extreme conditions, the battery needs to be cooled. At this time, the system enables the following operating modes. The high-temperature and high-pressure refrigerant gas discharged from the electric compressor 120 passes through the third heat exchanger 130 and the second expansion valve 140 and then enters the outdoor heat exchanger 150 to release heat to the external environment to condense the internal refrigerant into a supercooled refrigerant. Pass through the one-way valve 310, and then throttle through the first expansion valve 530 to become a low-temperature and low-pressure two-phase refrigerant, and then flow to the second heat exchanger 710 to cool the high-temperature circulating fluid from the battery cooling plate 720, and the second heat exchanger The low-temperature near-saturated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com