Electric valve

An electric valve and valve seat technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of poor axial positioning ability of the coil and loose coil positioning, and achieve the effect of ensuring dryness, reliable fixing relationship and ensuring elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following describes the implementation in detail in conjunction with the accompanying drawings.

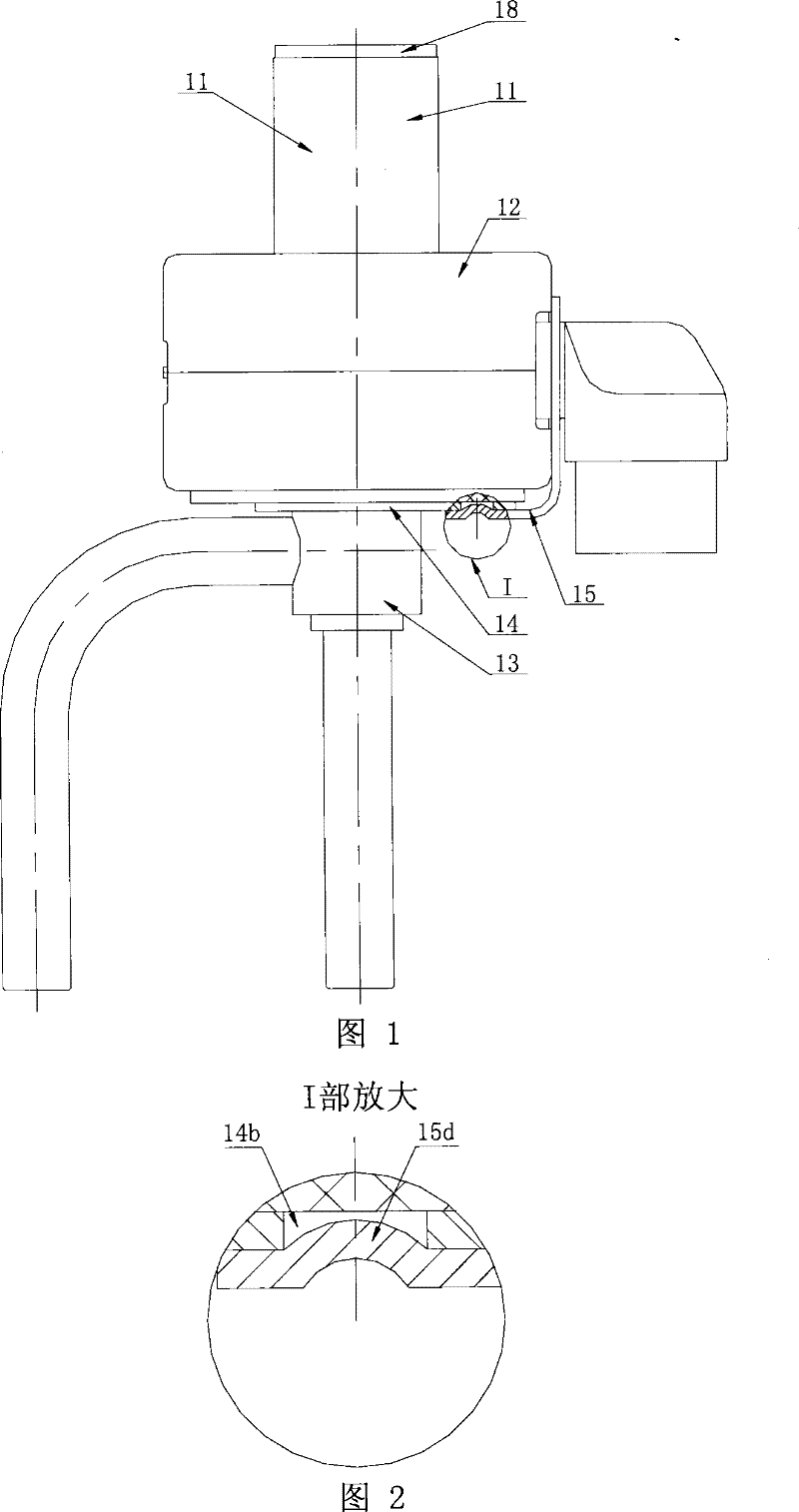

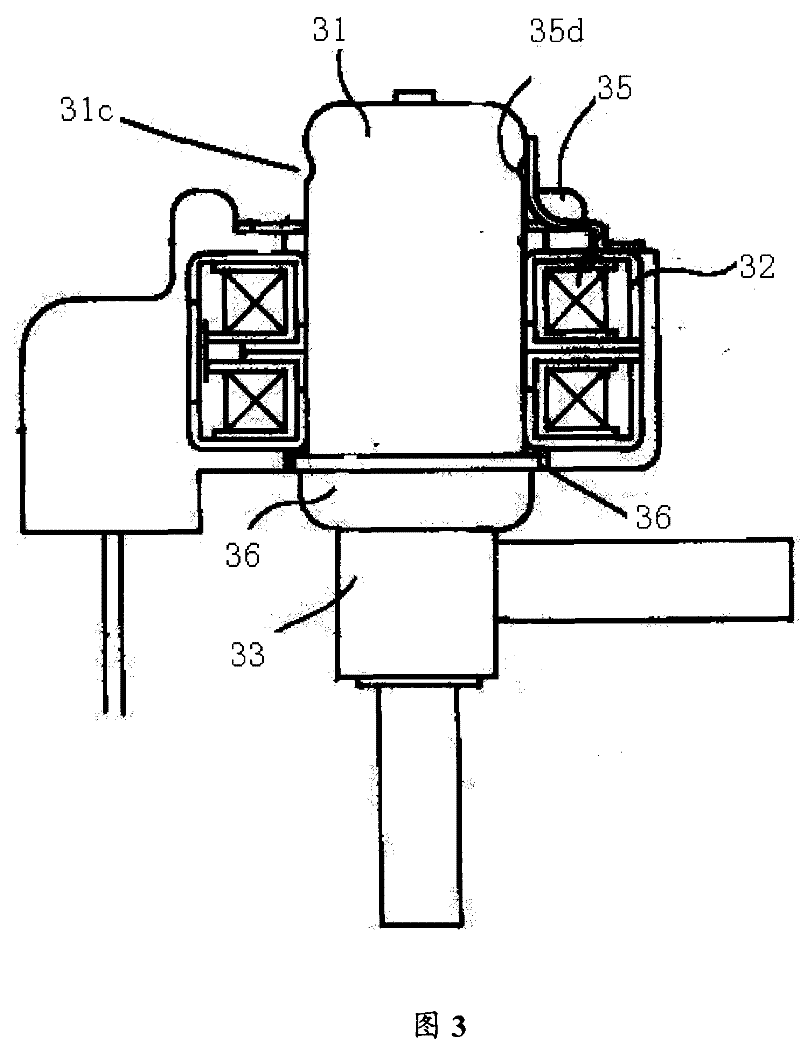

[0038] The electric valve of the present invention realizes the reliable positioning of the coil by improving the structure and connection relationship between the coil fixing frame and the positioning card; at the same time, the matching relationship between the welding parts is combined with the optimally designed weld position to improve the electric valve. High pressure capability.

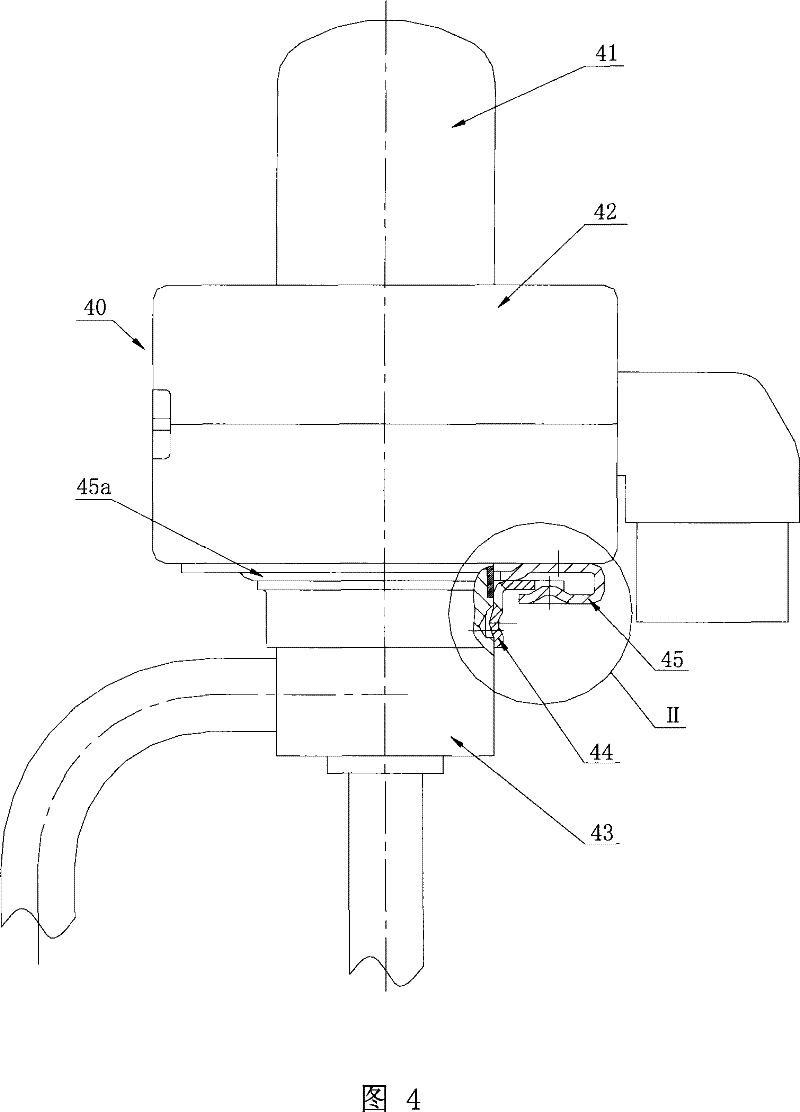

[0039] see Figure 4 , which is a schematic diagram of the overall structure of the present invention.

[0040] The main structure of the solenoid valve of the present invention is the same as that of the prior art. As shown in this figure, it includes a magnetic rotor (not shown) and a valve needle (not shown) placed in the housing 41, a stator 40, a valve seat 43, a positioning card 45 and a coil holder 44; wherein, the stator 40 is a yoke made of a coil box 42, a soft magnetic mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com