Multi-functional combination tool for machining stepped holes

A multi-functional combination and stepped hole technology, applied in the field of processing tools, can solve the problems of simultaneous processing, only replacement of blades, replacement of blades, etc., to improve work efficiency, simplify processing procedures, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

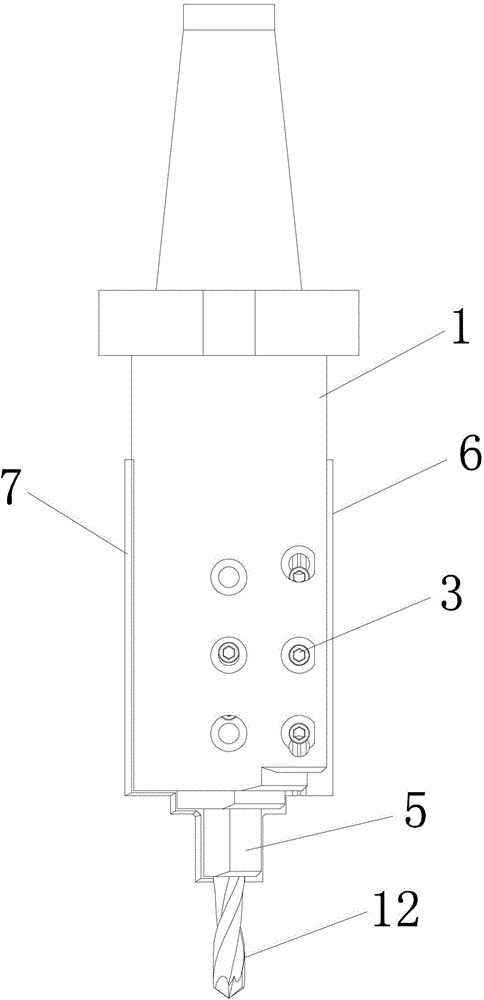

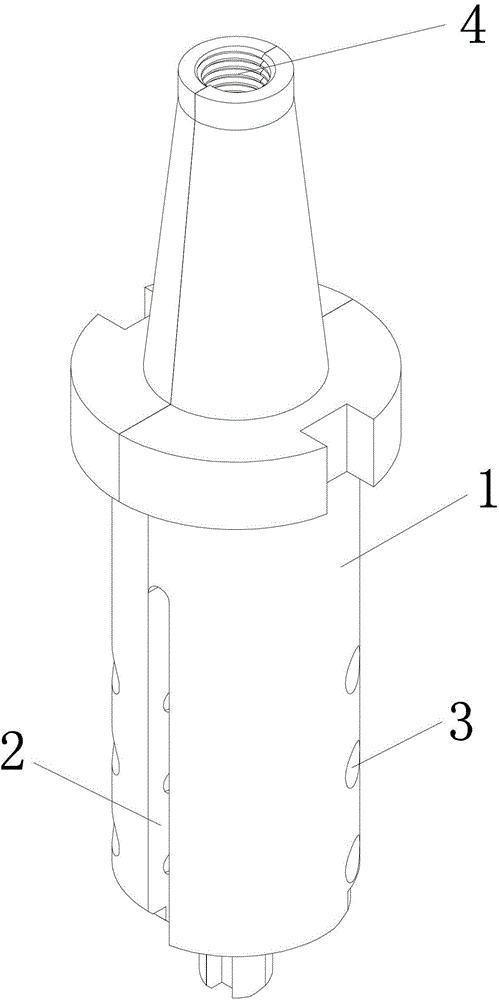

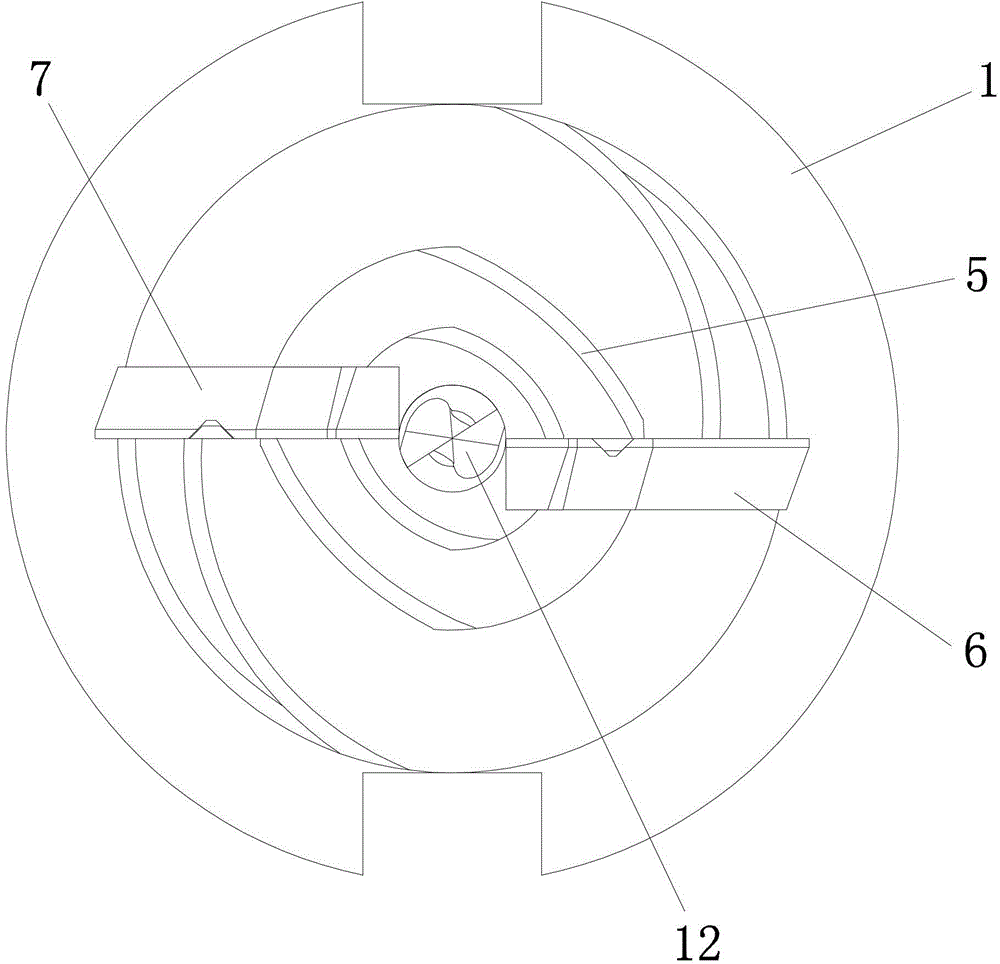

[0024] Example 1: Such as figure 1 As shown, a special multifunctional combined tool for processing stepped holes includes a tool holder 1 and a blade. The end of the tool holder 1 away from the blade is tapered. The blade includes an end processing blade 6 and a radial processing blade 7. The end of the tool holder 1 is provided with a clamping groove 2 and a drill bit positioning hole. The drill bit positioning hole is located at the axis of the tool holder 1, and a drill bit 12 is installed in the drill bit positioning hole. The clamping groove 2 includes a first clamping portion and a second clamping portion. The first clamping portion is used for fixing the end processing blade 6 and the second clamping portion is used for fixing the radial processing blade 7. Such as image 3 As shown, the first clamping portion and the second clamping portion are respectively located on both sides of the drill positioning hole, the first clamping portion is located on the cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com