Vacuum absorption adjusting platform for milling and grinding

A vacuum adsorption and adjustment table technology, which is applied in the direction of grinding machines, optical surface grinders, grinding/polishing equipment, etc., can solve the position change of milling and grinding vertices, reduce the milling and grinding precision, and the radial and axial non-uniform errors of the position of optical components To achieve the effect of compensating the error of uneven distribution of axial deformation, ensuring positioning accuracy and realizing flexible sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will take the accompanying drawings as an example to illustrate the connotation of the present invention. Any insubstantial improvements and embellishments made by those skilled in the art on the basis of the present invention fall within the scope of the present invention.

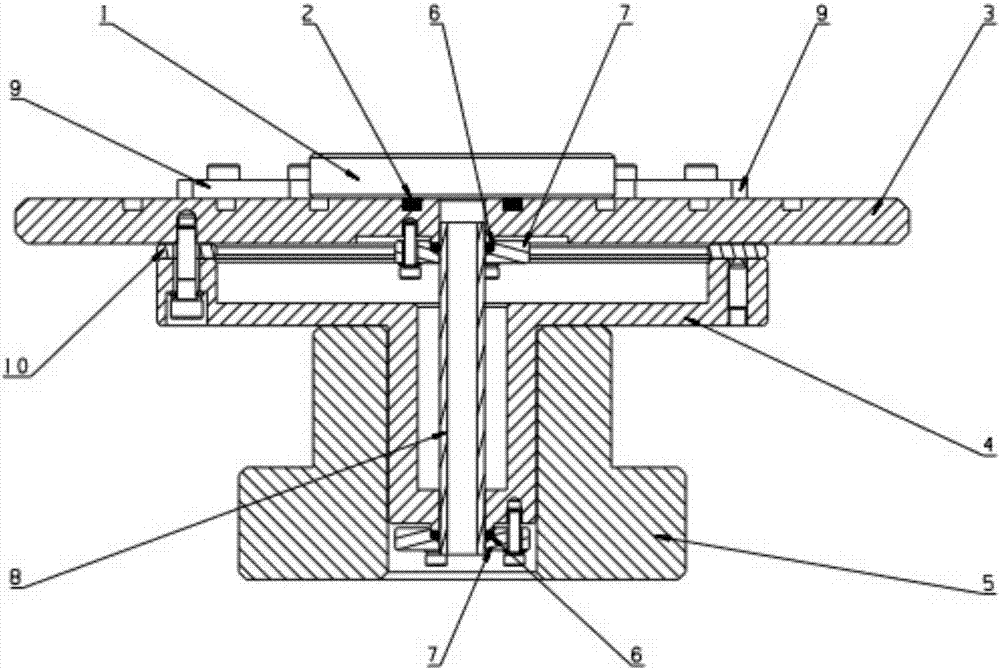

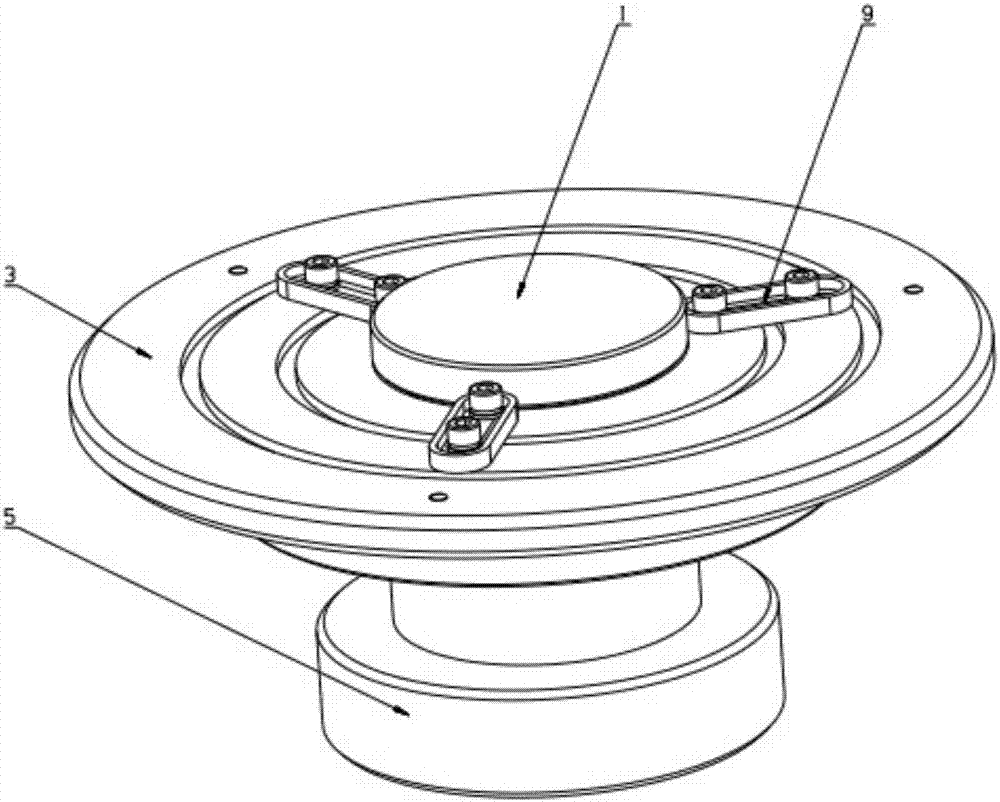

[0021] Such as figure 1 In the shown embodiment, the circular optical element 1 is radially positioned on the workpiece mounting table 3 under the action of three evenly distributed stoppers 9, and the corresponding concentric annular sealing groove of the disc-shaped workpiece mounting table 3 Place the O-ring 6 of the corresponding size, the lower end of the workpiece mounting table 3 is connected to the rubber hose 8, the upper end of the rubber hose 8 runs through the small O-ring 6 and is sealed under the pressure of the sealing end cover 7 of the rubber hose, and the lower end of the rubber hose 8 runs through The small O-shaped sealing ring 6 passes through the lower end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com