A turbine blade with transverse meandering and alternately shortening and shortening channels inside

A technology of turbine blades and short passages, which is applied to the supporting components of blades, machines/engines, mechanical equipment, etc., can solve the problems of ineffective air film and low cooling efficiency, so as to improve cooling conditions, increase heat exchange capacity, Enhanced internal cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

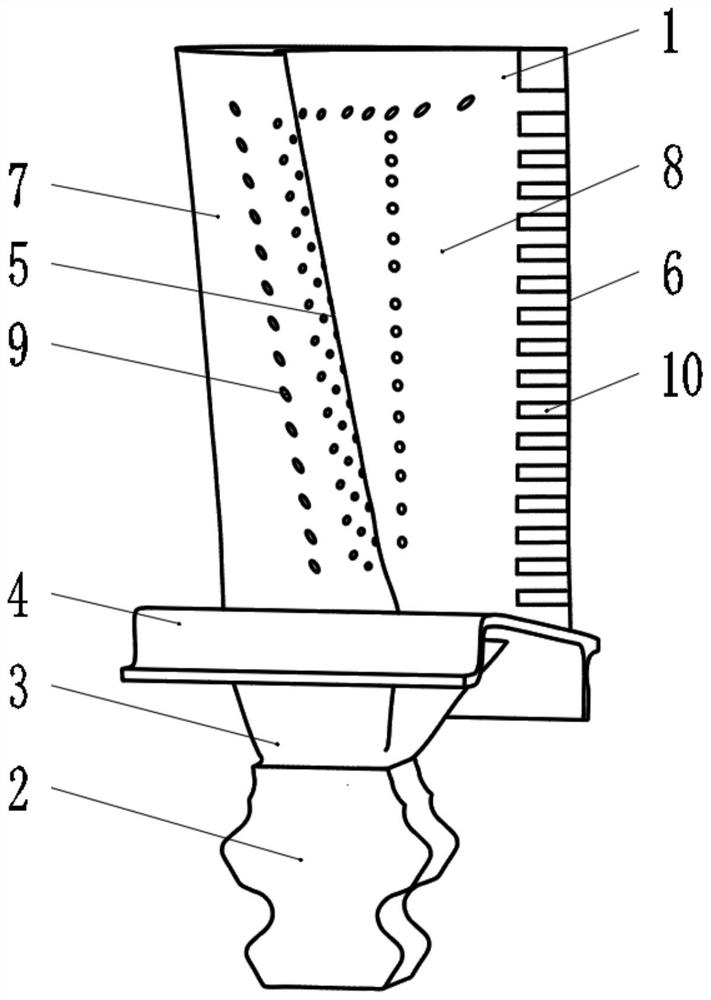

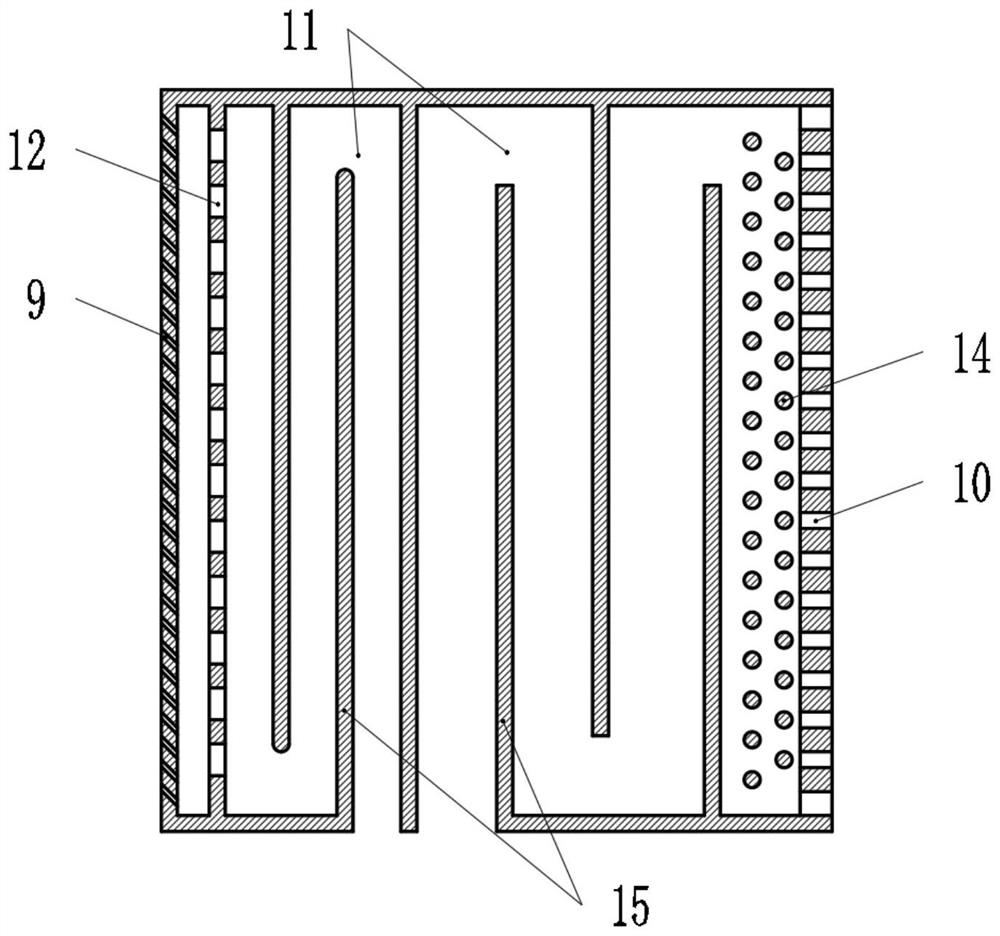

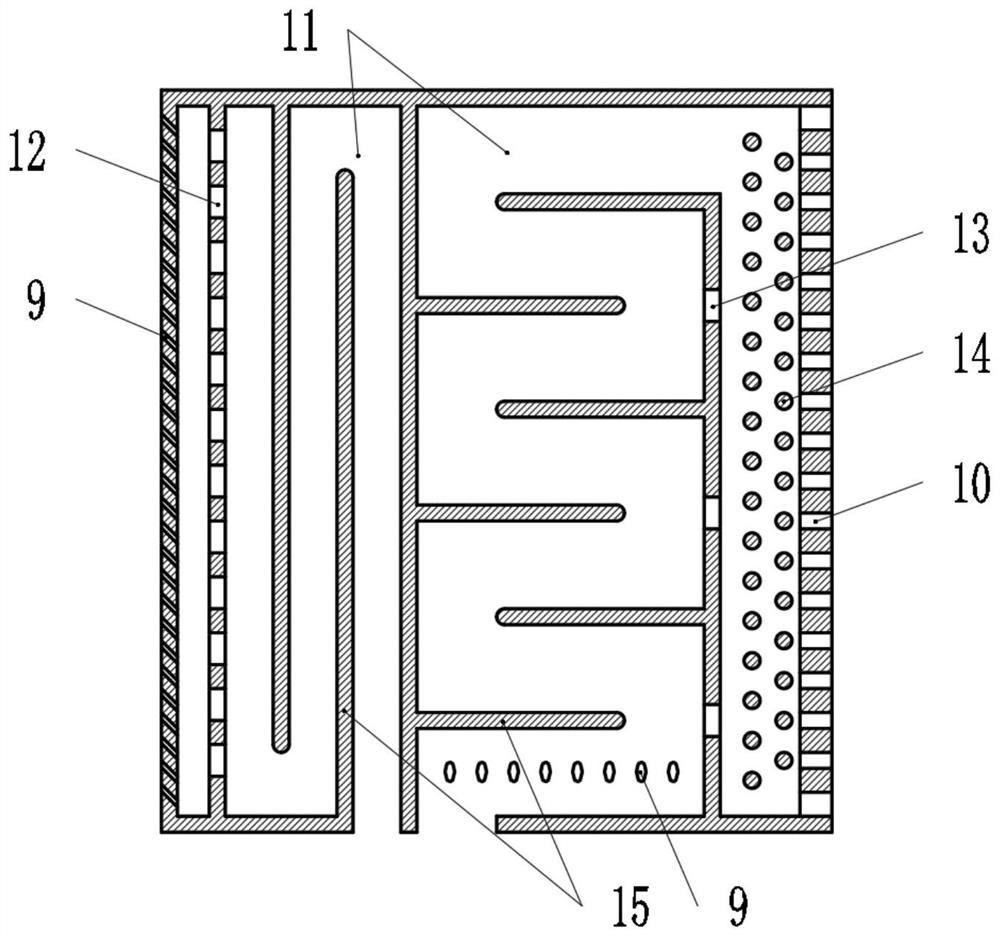

[0032] When the chord length of the turbine rotor blade in this embodiment is 37mm and the blade height (blade body 1 height) is 44mm, the thickness of the inner rib 15 is 1mm. The aspect ratio of the short channel is 2.92, the expansion ratio is 1:7, and the maximum section aspect ratio of the channel is 1.23. The number of channels is 7, and the number of corners is 6. The air film holes 9 are arranged in the second half of the root of the suction surface 7, the hole diameter is 0.5mm, the hole spacing is 1.5mm, the jet angle is 30°, and the azimuth angle is 60°. The overflow hole 14 is arranged in the center of the outer wall of the U-shaped bend near the trailing edge 6 of the meandering channel 11 distributed along the chord direction, and the cross-section is a rectangle of 1*2 mm; The cooling efficiency is increased by 13-18%.

Embodiment 2

[0034] When the chord length of the turbine rotor blade in this embodiment is 44mm and the blade height (blade body 1 height) is 53mm, the thickness of the inner rib 15 is 1.5mm. The aspect ratio of the short channel is 3, the shrinkage ratio is 1:6, and the maximum section aspect ratio of the channel is 1.3. The number of channels is 7, and the number of corners is 6. The air film holes 9 are arranged in the second half of the root of the suction surface 7, the hole diameter is 0.6mm, the hole spacing is 2mm, the jet angle is 30°, and the azimuth angle is 75°. The overflow hole 14 is arranged in the center of the outer wall of the U-shaped bend near the trailing edge 6 of the meandering channel 11 distributed along the chord direction, and has a rectangular cross-section of 1.2*2.5mm; the second half of the root of the suction surface 7 of the turbine rotor blade The overall cooling efficiency is increased by 15-20%.

Embodiment 3

[0036] When the chord length of the turbine rotor blade in this embodiment is 45mm and the blade height (blade body 1 height) is 69mm, the inner rib 15 is 2mm thick. The aspect ratio of the short channel is 3.2, the expansion ratio is 1:5.5, and the maximum section aspect ratio of the channel is 1.35. The number of channels is 9, and the number of corners is 8. The air film holes 9 are arranged in the second half of the root of the suction surface 7, the hole diameter is 0.8mm, the hole spacing is 2.5mm, the jet angle is 45°, and the azimuth angle is 90°. The overflow hole 14 is arranged in the center of the outer wall of the U-shaped bend near the trailing edge 6 of the meandering channel 11 distributed along the blade chord direction, and the cross section is a rectangle of 1.5*3 mm; The cooling efficiency is increased by 17-22%.

[0037] The present invention is different from the longitudinal meandering channel 11 with the length-to-diameter ratio exceeding 10. The lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com