Patents

Literature

44results about How to "Take away much" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

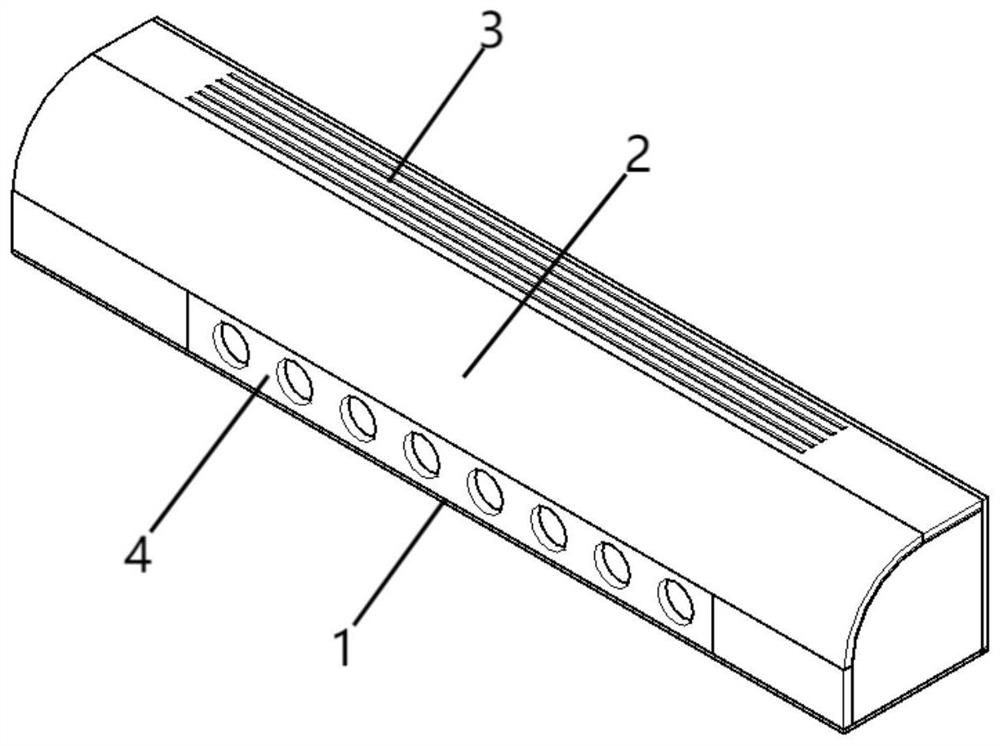

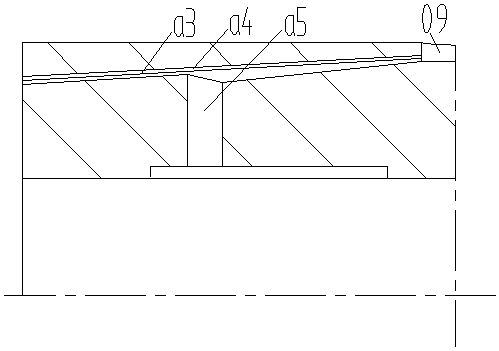

Silicon carbide micro-channel heat dissipation structure of three-dimensional integrated circuit and manufacturing method thereof

ActiveCN107240578AImprove thermal conductivityAuxiliary cooling effect is goodSemiconductor/solid-state device detailsSolid-state devicesState of artThree-dimensional integrated circuit

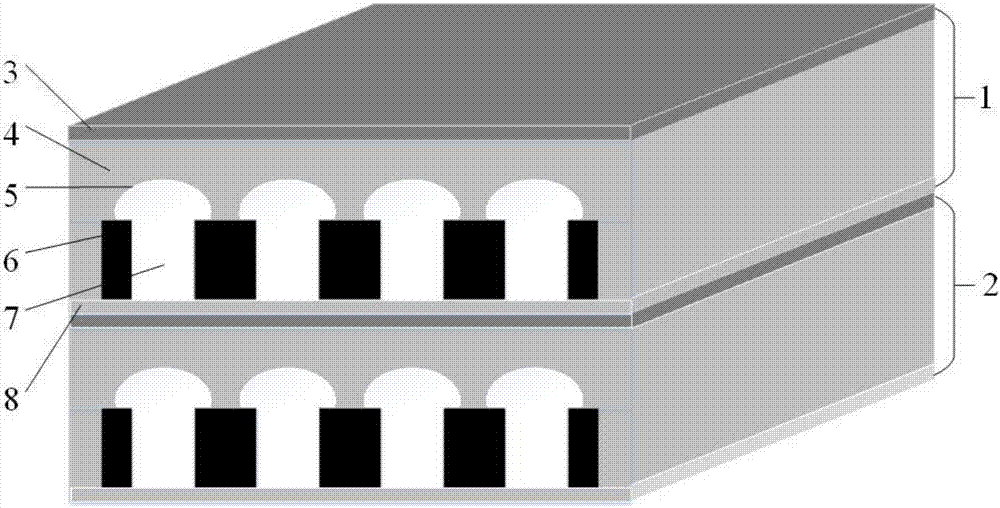

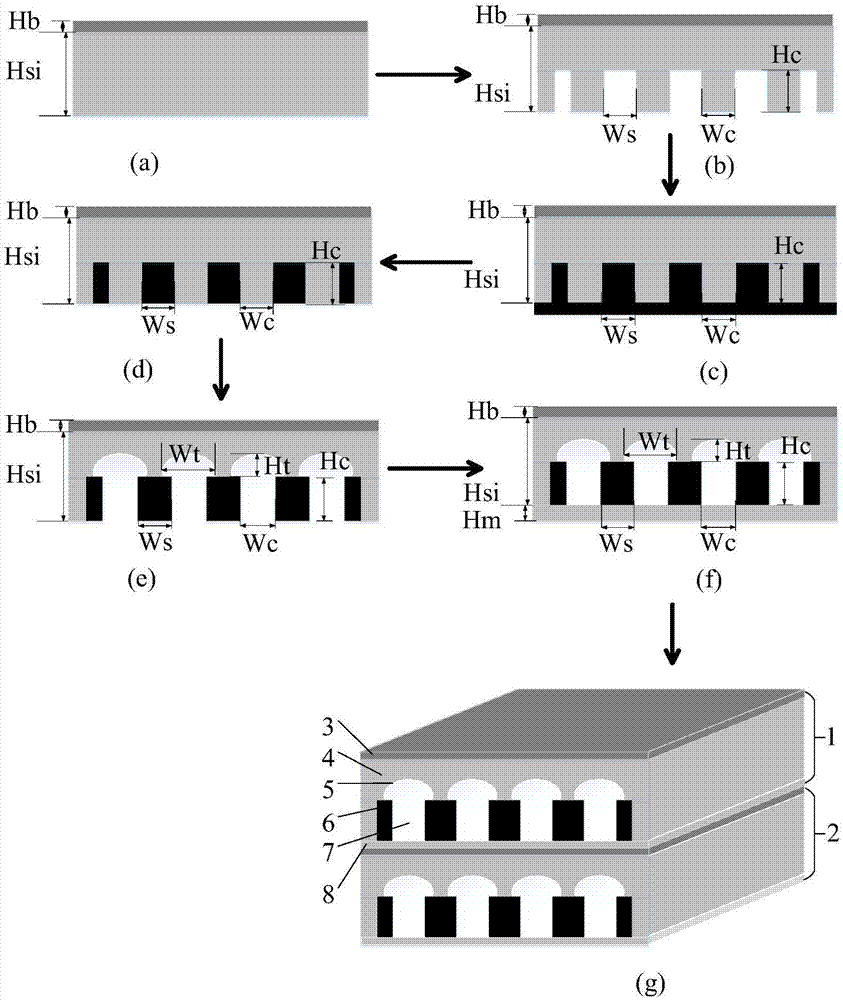

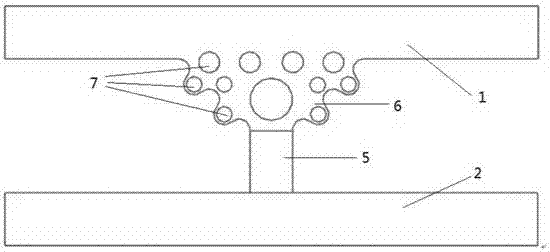

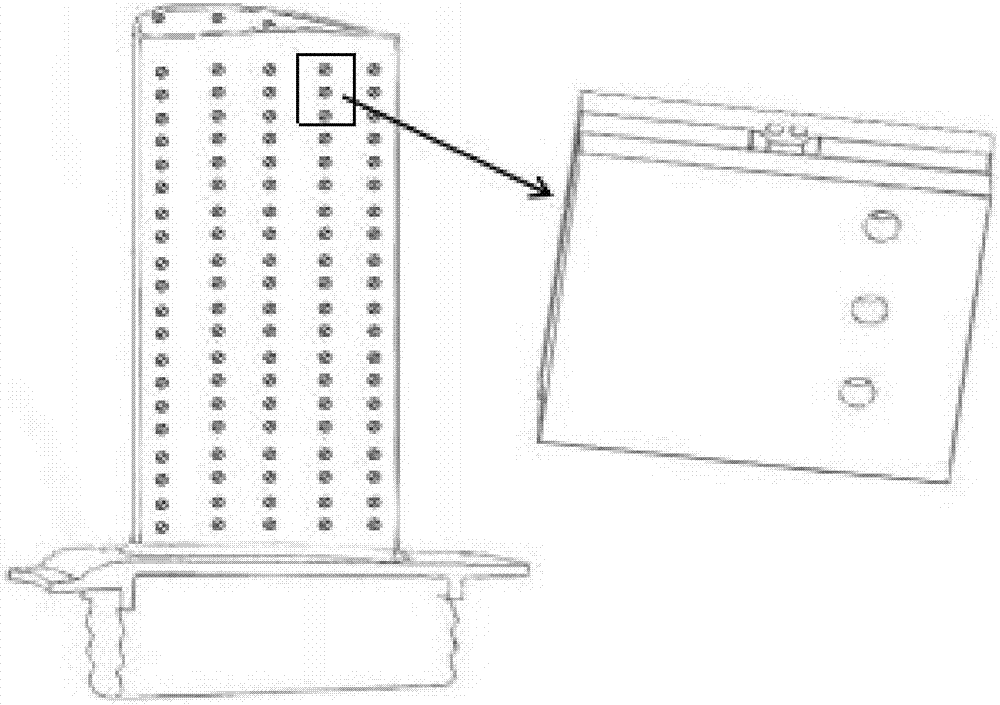

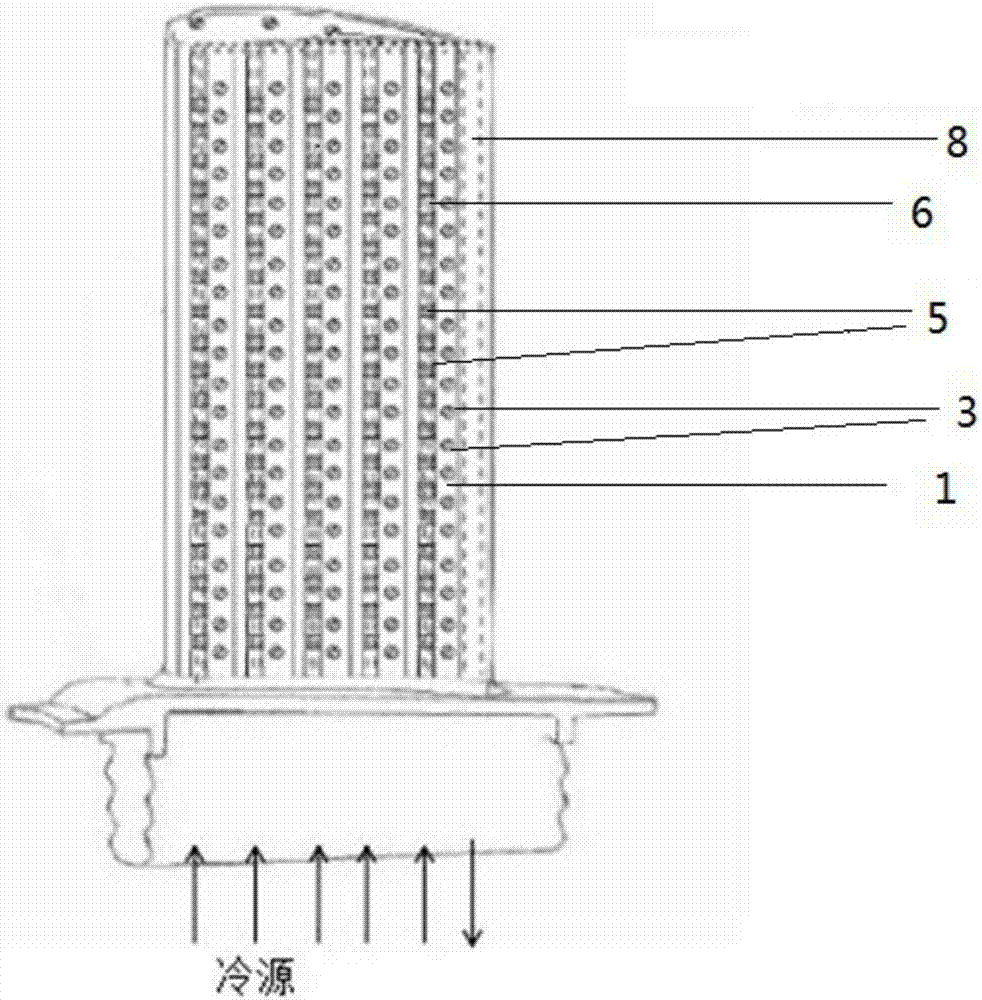

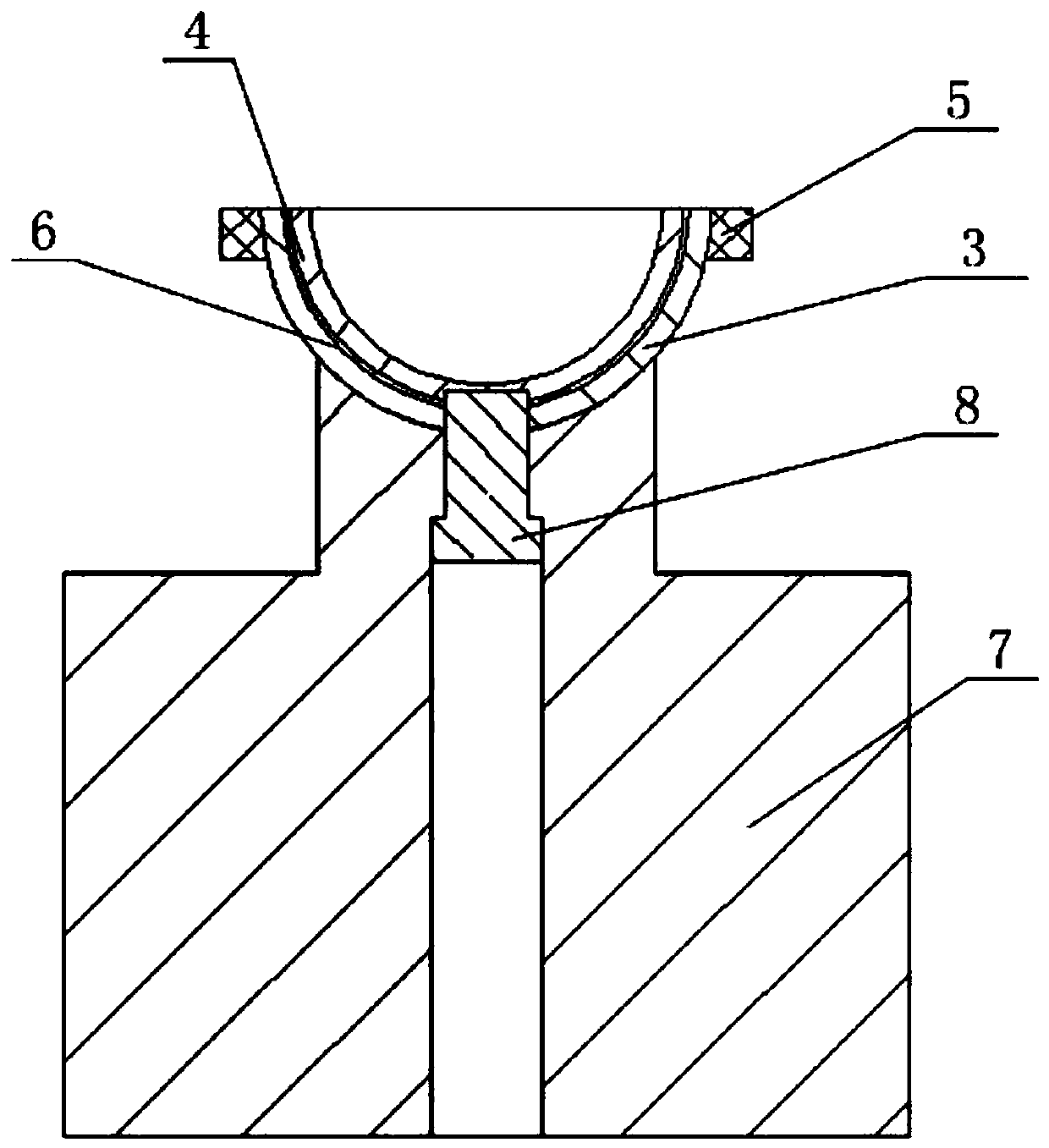

The invention relates to a silicon carbide micro-channel heat dissipation structure of a three-dimensional integrated circuit and a manufacturing method thereof, and mainly solves the problem that a micro-channel wall material is low in heat conductivity and small in contact area with the micro-channel wall in the prior art. The silicon carbide micro-channel heat dissipation structure comprises an upper chip (1) and a lower chip (2), wherein each chip comprises a circuit layer (3), a silicon substrate (4), a silicon channel wall (5), a silicon carbide channel wall (6), a micro-channel (7) and a silicon micro-channel cap (8) from top to bottom, wherein each circuit layer is positioned on the top of the front side of the corresponding chip, and each silicon substrate is adjacent to the corresponding circuit layer and is positioned below the corresponding circuit layer; each silicon channel wall is adjacent to the corresponding silicon substrate and is positioned below the corresponding silicon substrate; each silicon carbide channel wall epitaxially grows below the corresponding silicon channel wall; the cross section of each micro-channel is of an integral structure with a semi-elliptical upper part and a rectangular lower part, and each micro-channel is positioned below the corresponding silicon channel wall. The heat dissipation contact area close to the circuit layers is increased, the distances with the circuit layers are shortened, and the heat dissipation performance of the micro-channel heat dissipation structure is improved.

Owner:XIDIAN UNIV

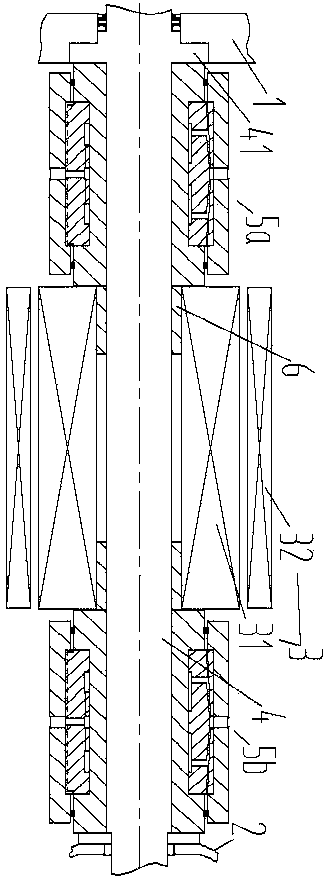

Diameter-changeable pulsating heat pipe

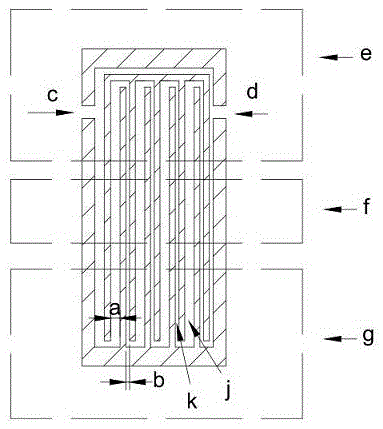

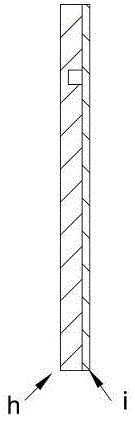

The invention discloses a diameter-changeable pulsating heat pipe. The diameter-changeable pulsating heat pipe comprises an evaporation section, a heat insulating section and a condensation section. A pulsating heat pipe vacuumizing opening and a pulsating heat pipe working medium filling opening are formed in the left end and the right end of the condensation section correspondingly. Upper bends and lower bends of the pulsating heat pipe are connected with adjacent main channels with different hydraulic diameters and the main channels with the different hydraulic diameters are distributed and connected in the shape of an S on a whole silicon plate. The diameter-changeable pulsating heat pipe has the advantages of being simple in structure, good in heat transferring performance and easy to miniaturize. Meanwhile, compared with traditional pulsating heat pipes, the outstanding effects that the large pressure difference can be formed more easily compared with the traditional pulsating heat pipes during starting by the aid of the hydraulic diameter differences of the bends of the pulsating heat pipe, frictional resistance and shearing stress are overcome and accordingly the starting time is shortened, the pulsating heat pipe can take more heat away from the evaporation section due to the hydraulic diameter differences of the bends of the pulsating heat pipe compared with the traditional heat pipes, and meanwhile the heat exchange frequency is increased are achieved.

Owner:NANCHANG UNIV

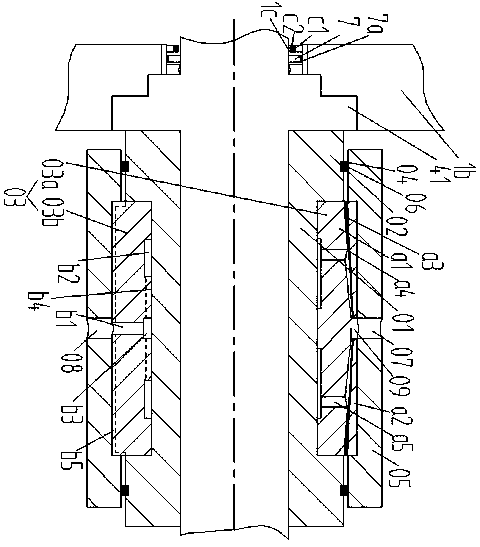

Gas-liquid coupling turbine blade cooling unit

ActiveCN107060892AImprovement of double shell type "shock/air film/disturbance" composite cooling structureReduce the temperatureBlade accessoriesMachines/enginesTurbine bladeEngineering

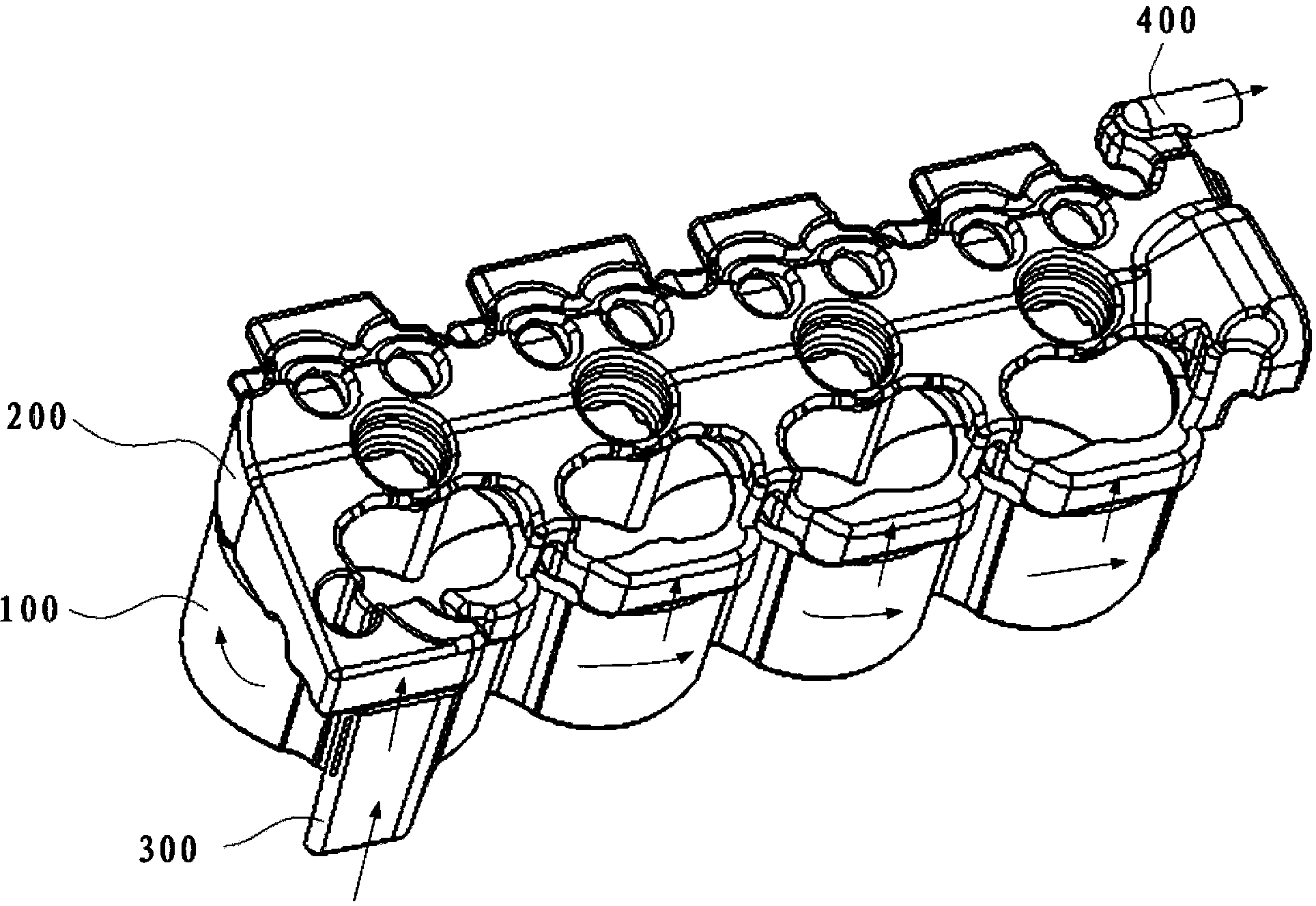

Based on an existing double-layer shell type impact / gas film / turbulent flow composite cooling structure, the invention discloses a gas-liquid coupling turbine blade cooling unit. The gas-liquid coupling turbine blade cooling unit comprises a plurality of mutually independent cooling subunits. Each cooling subunit comprises a cold gas wall, a hot gas wall, a plurality of impact holes formed in the cold gas wall, a plurality of gas film holes formed in the hot gas wall, a plurality of turbulent flow columns located between the cold gas wall and the hot gas wall, and a collecting table connected with the cold gas wall and the turbulent flow columns, wherein the cold gas wall and the hot gas wall are arranged oppositely, the upper surface of the collecting table is connected with the inner surface of the cold gas wall, the lower surface of the collecting table is connected with the turbulent flow columns, and at least one cold source pipeline penetrating through the collecting table longitudinally is arranged in the collecting table. Further, in the cooling subunits, the side walls of the collecting tables are smoothly connected with the inner surfaces of the cold gas walls and the side walls of the turbulent flow columns to form a smooth hook face structure together. Through the gas-liquid coupling turbine blade cooling unit, a liquid cooling path is added, and the overall temperature of a turbine is further lowered.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

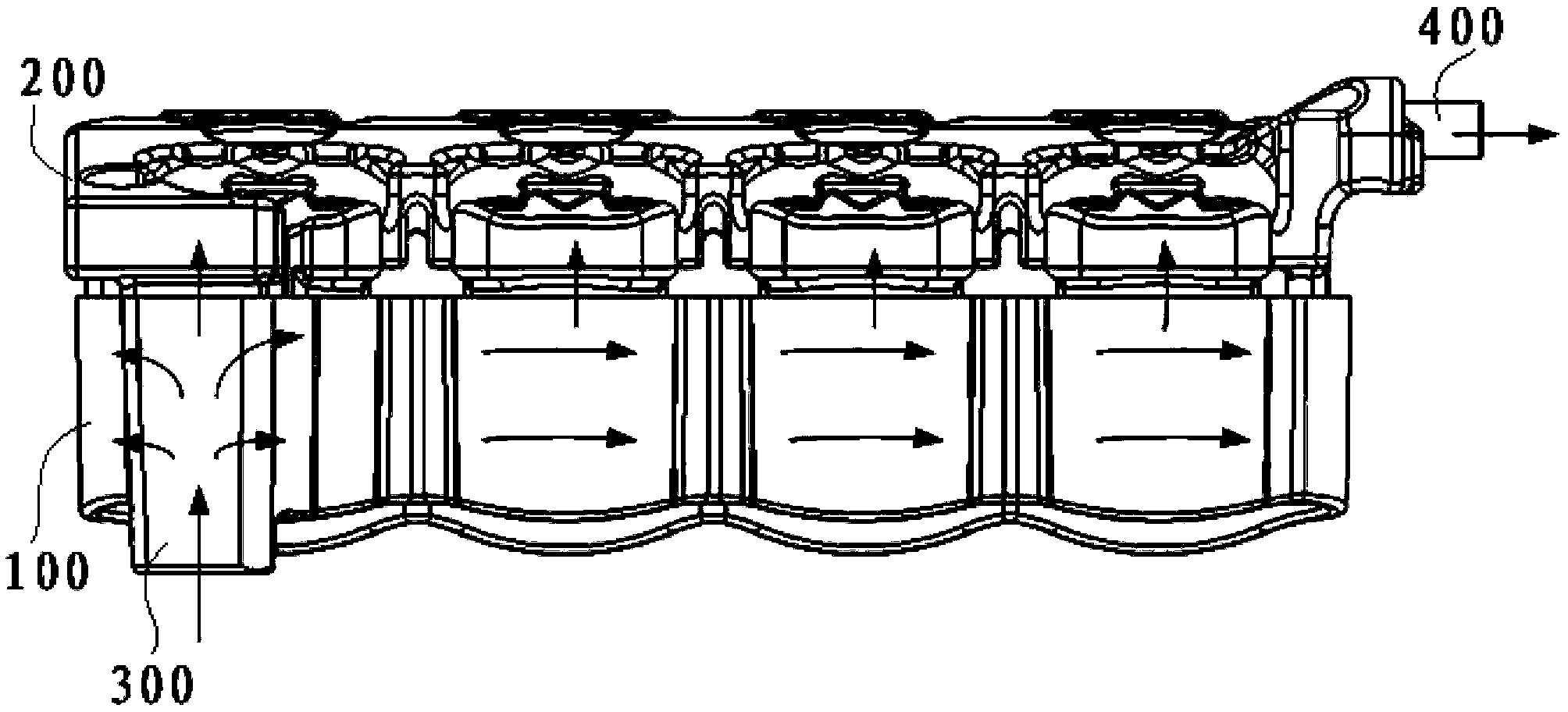

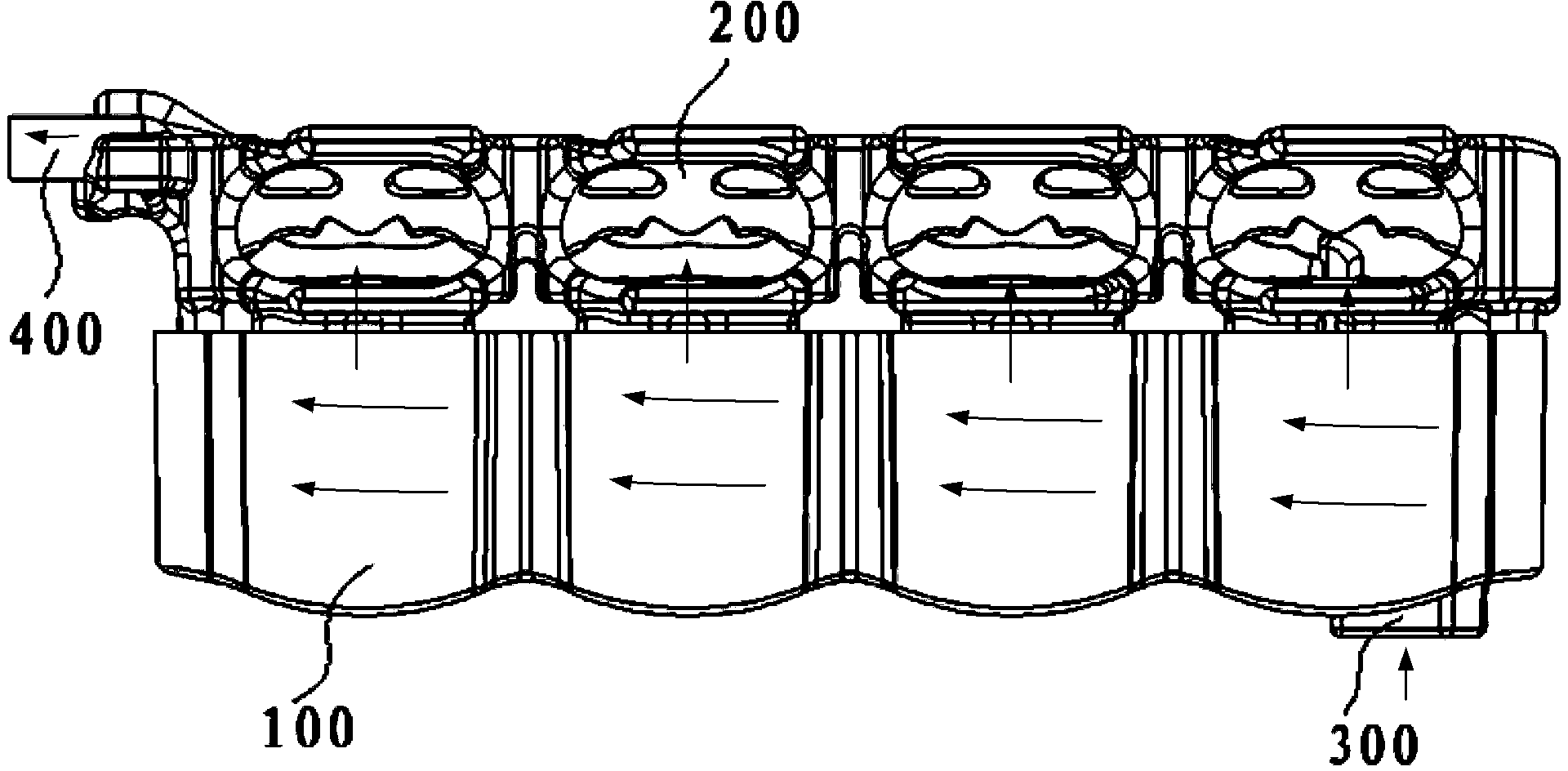

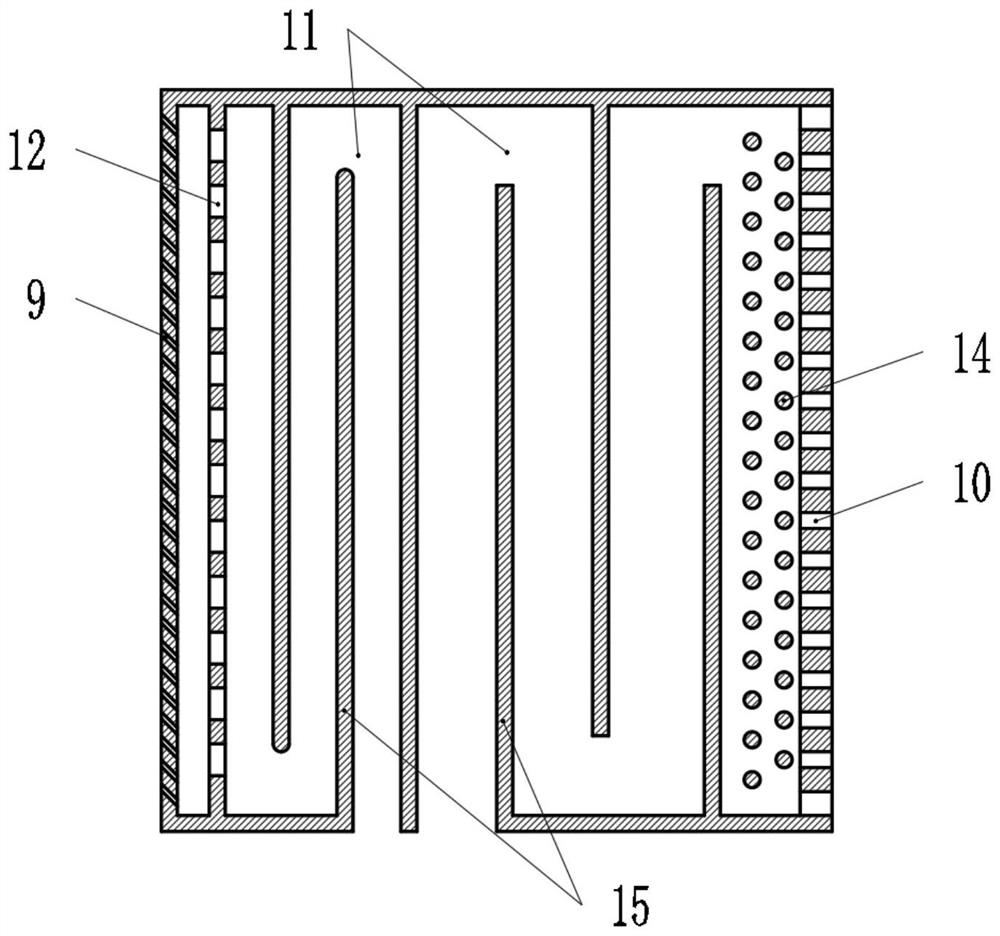

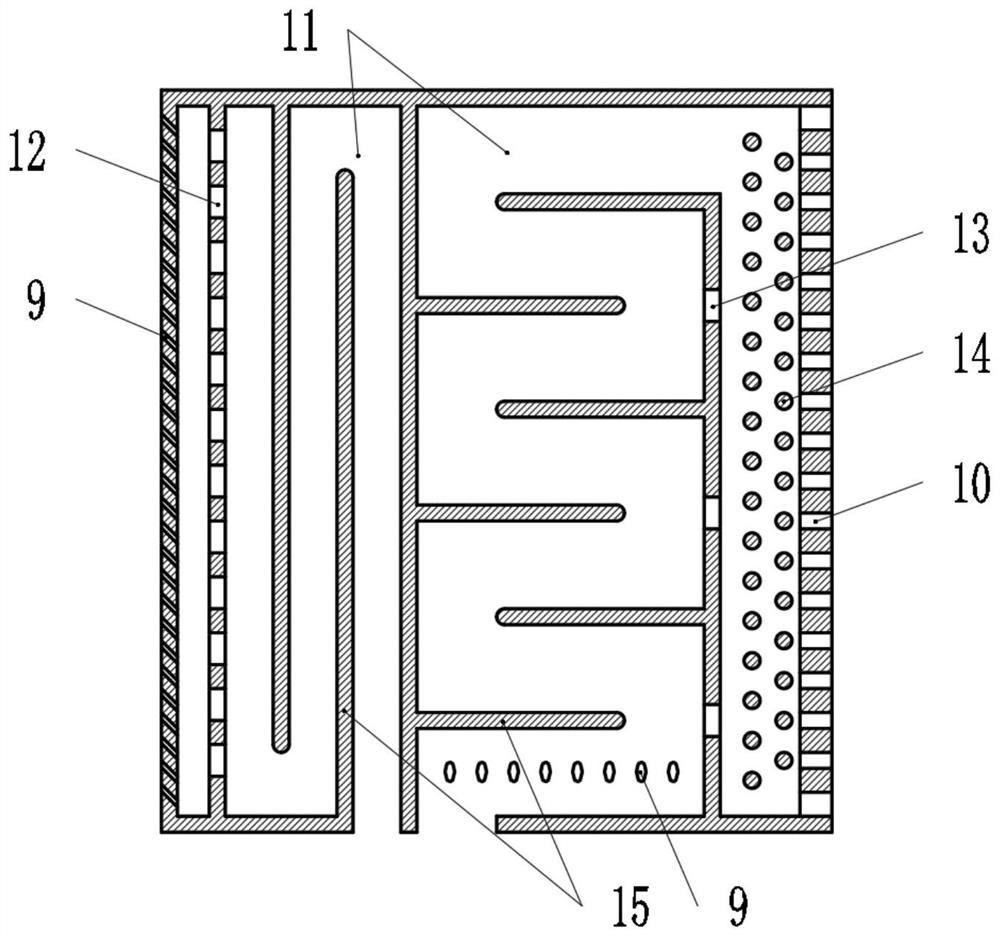

Engine cooling water jacket and engine cooling system

InactiveCN103670768AUniform cooling from top to bottomTake away muchCylinder headsCylindersWater jacketCylinder block

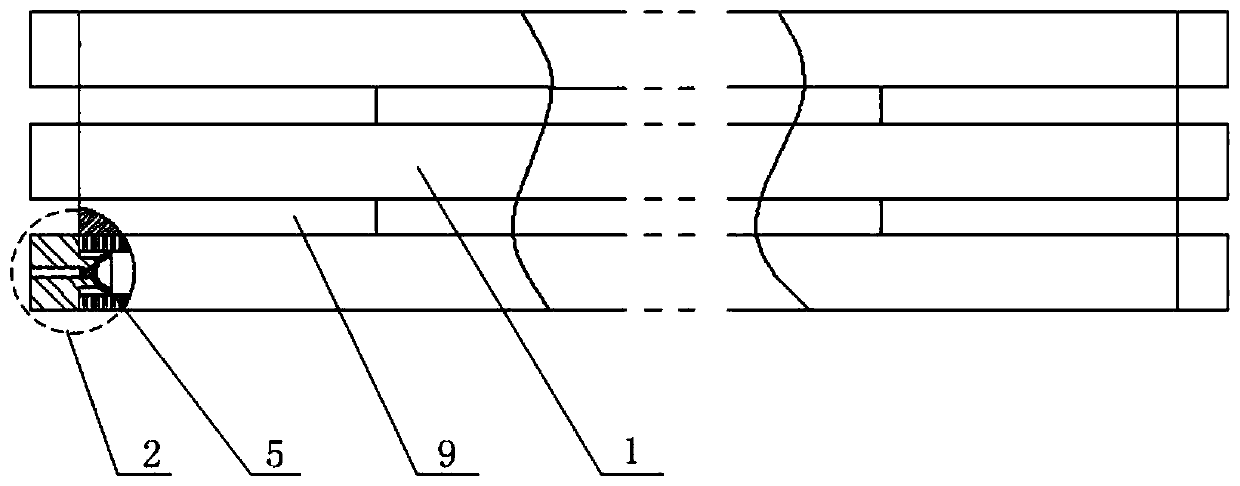

The invention provides an engine cooling water jacket and an engine cooling system. The engine cooling water jacket comprises a cylinder body water jacket formed in a cylinder body and mainly used for cooling the cylinder body, and a cylinder cover water jacket formed in a cylinder cover and mainly used for cooling the cylinder cover, wherein a water inlet is formed in one end of the cylinder body water jacket, a first cooling water channel communicated with the water inlet is formed inside the cylinder body water jacket, the cylinder cover water jacket is located above the cylinder body water jacket and is provided with a water outlet, a second cooling water channel communicated with the water outlet is formed inside the cylinder cover water jacket, the second cooling water channel is communicated with the first cooling water channel, and the first cooling water channel inside the cylinder body water jacket comprises at least two cooling waterways arranged in a layered mode from top to bottom along the cylinder body water jacket. Due to the fact that the first cooling water channel inside the cylinder body water jacket of the engine cooling water jacket is divided into the at least two cooling waterways by arranging guiding plates in a layered mode from top to bottom along the cylinder body water jacket, the upper portion and the lower portion of the cylinder body can be cooled evenly.

Owner:北京汽车动力总成有限公司

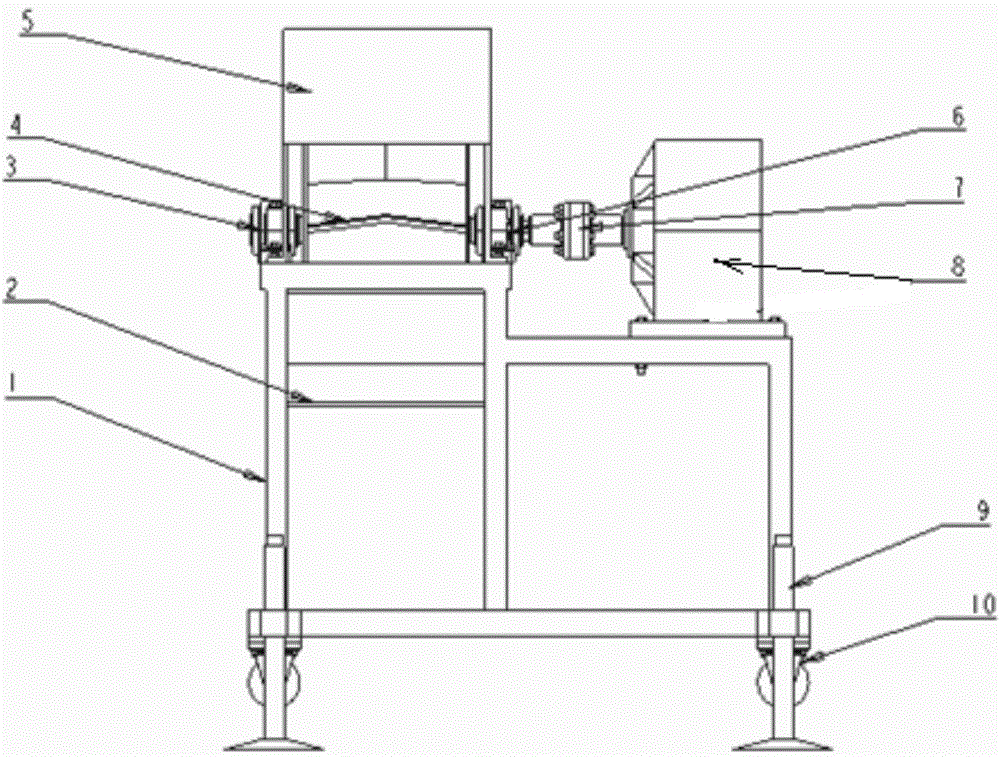

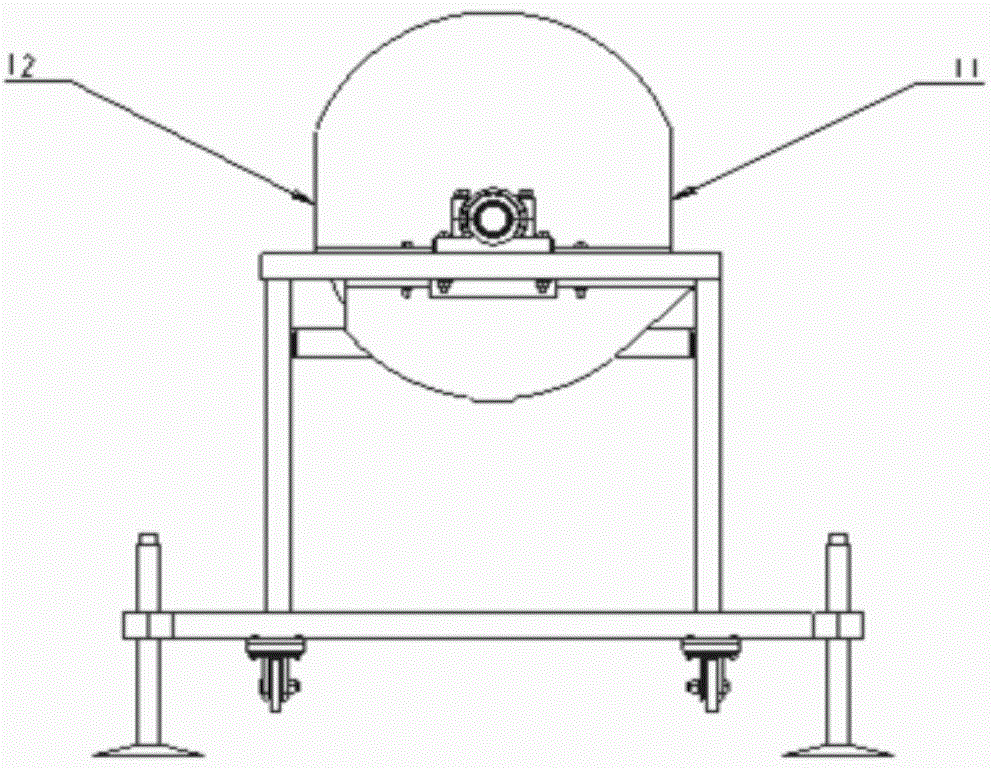

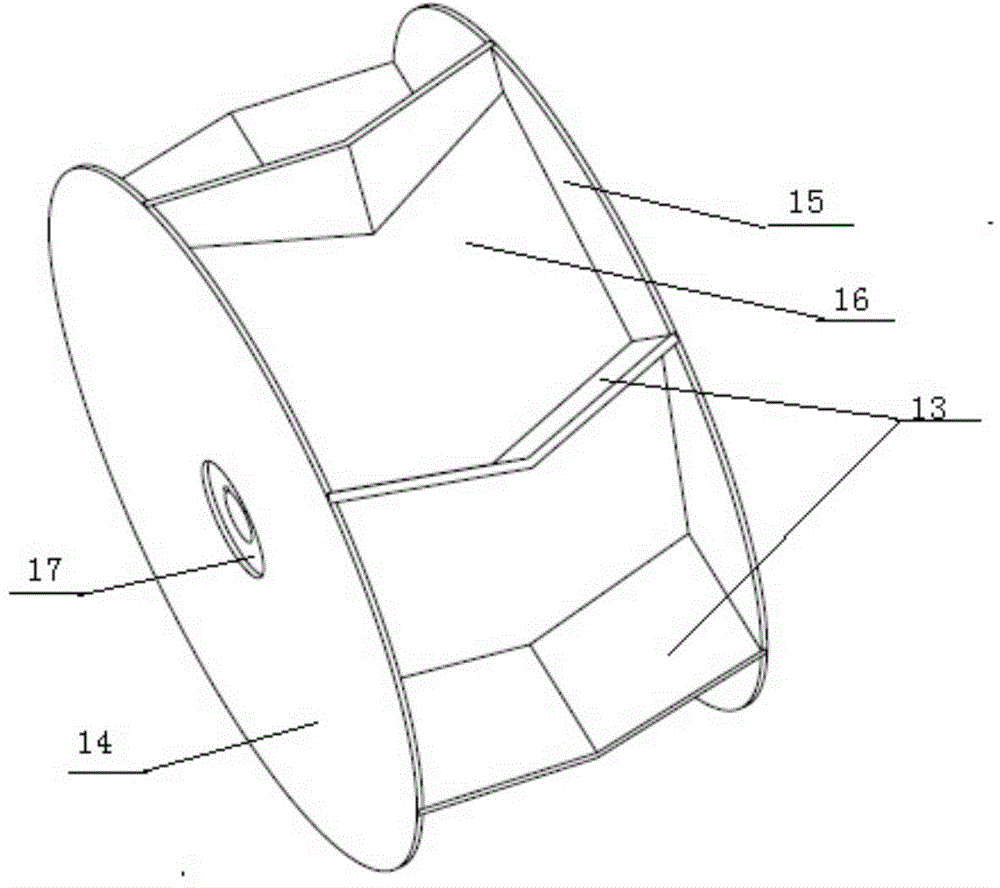

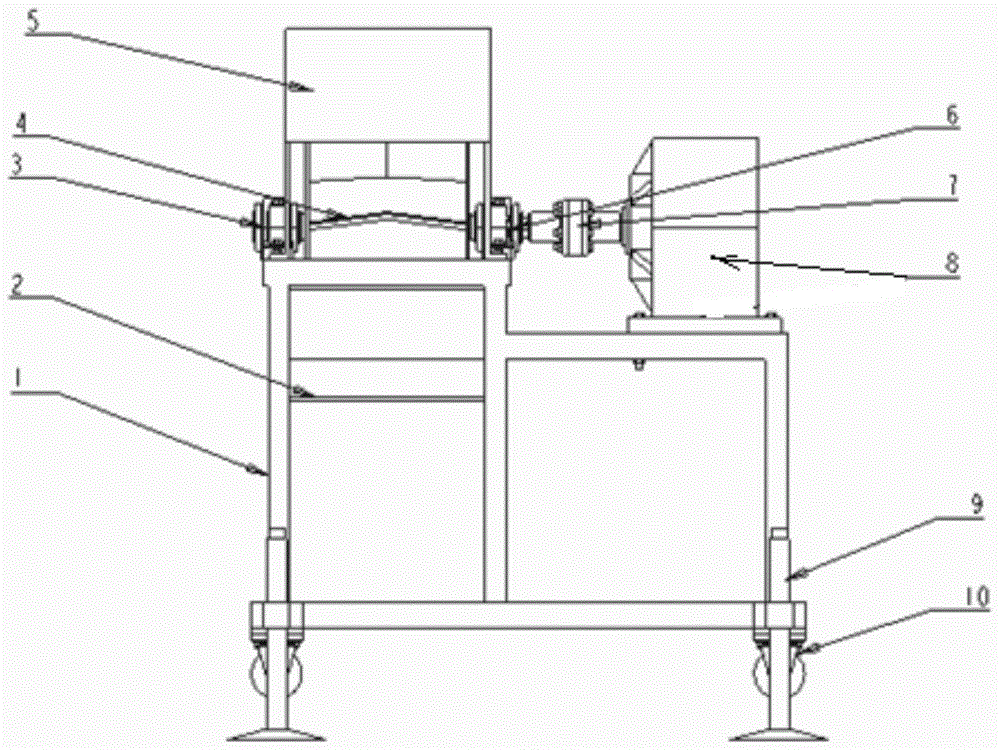

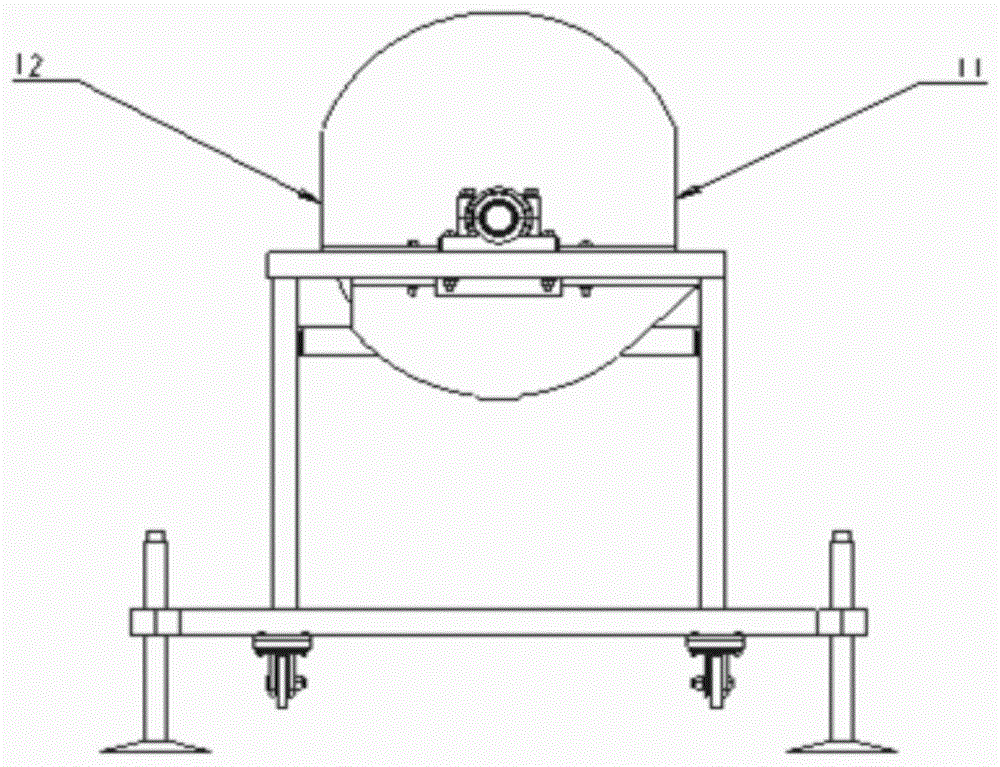

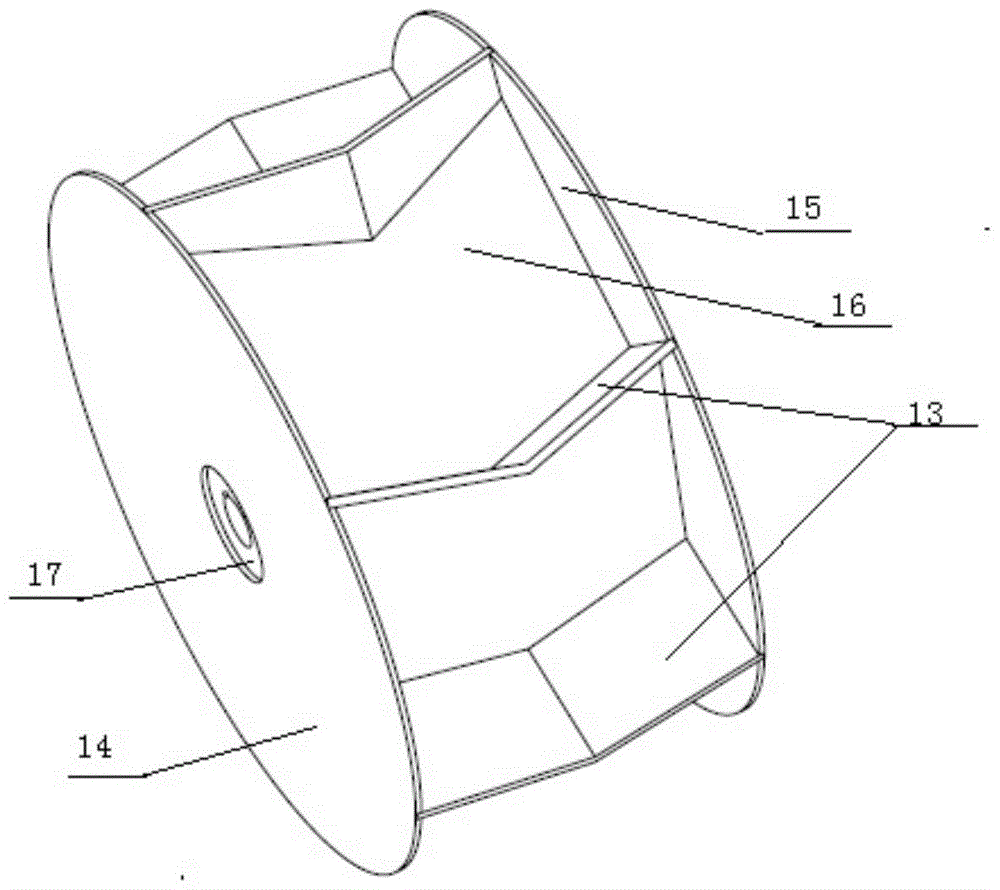

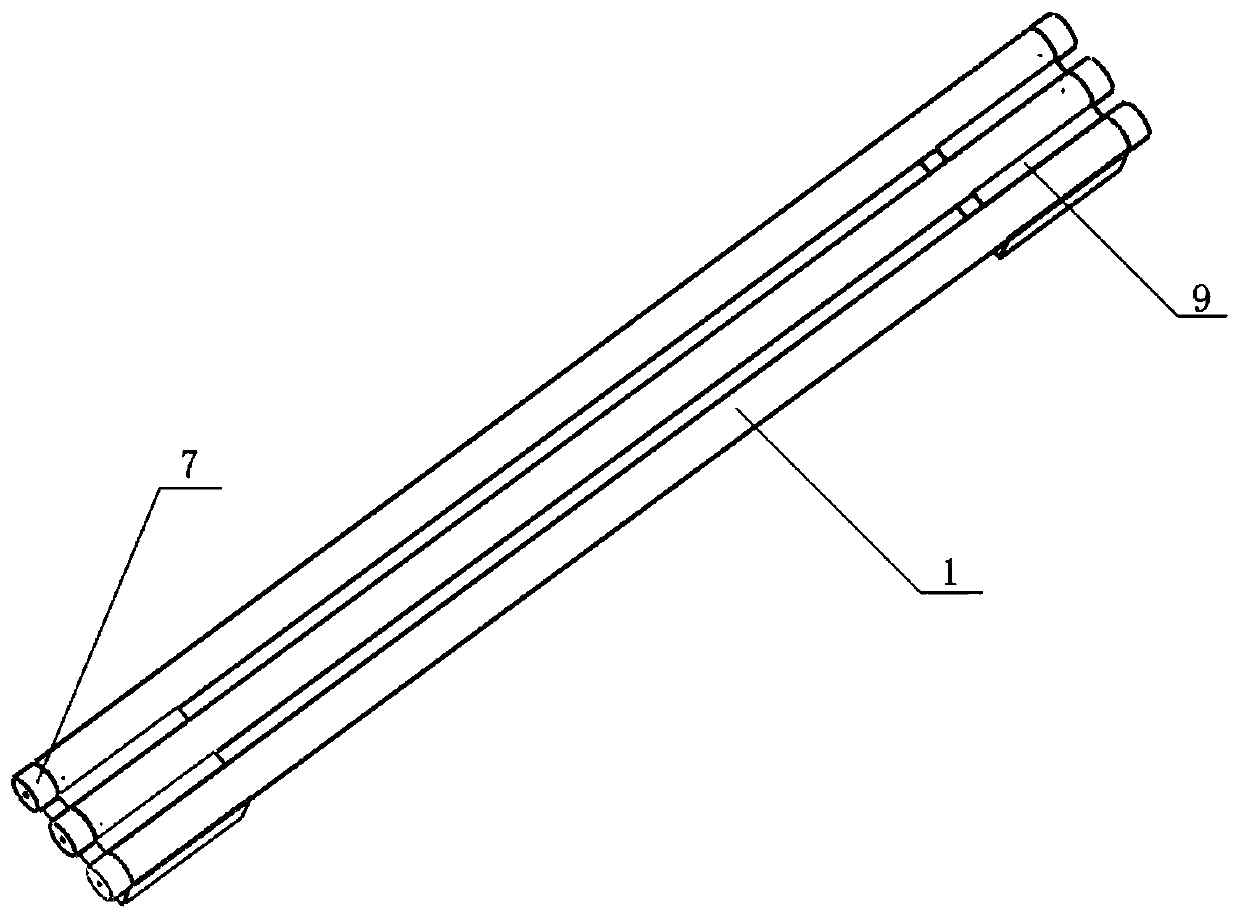

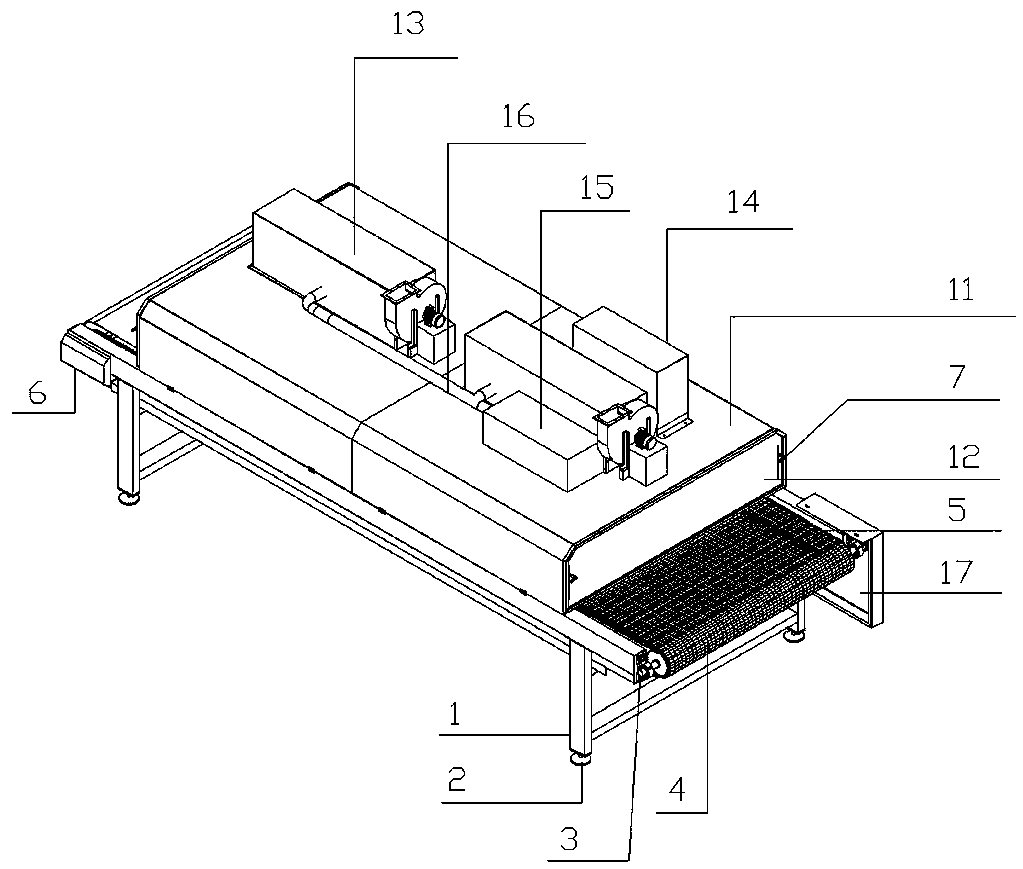

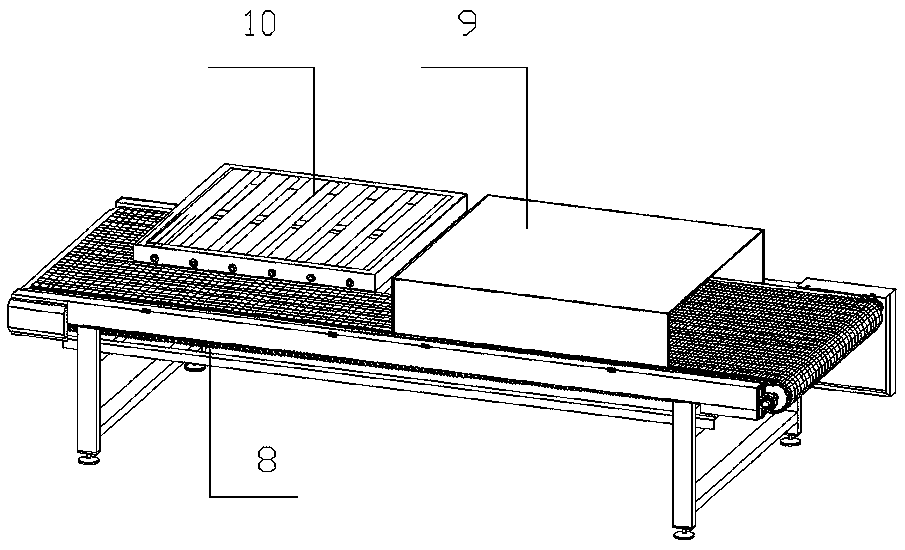

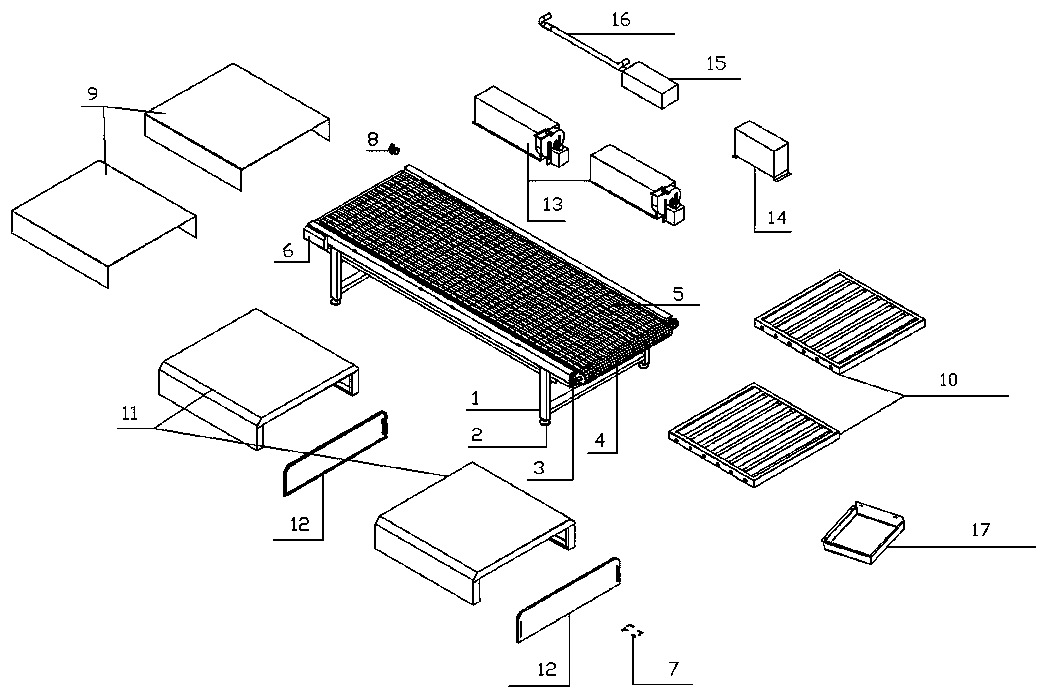

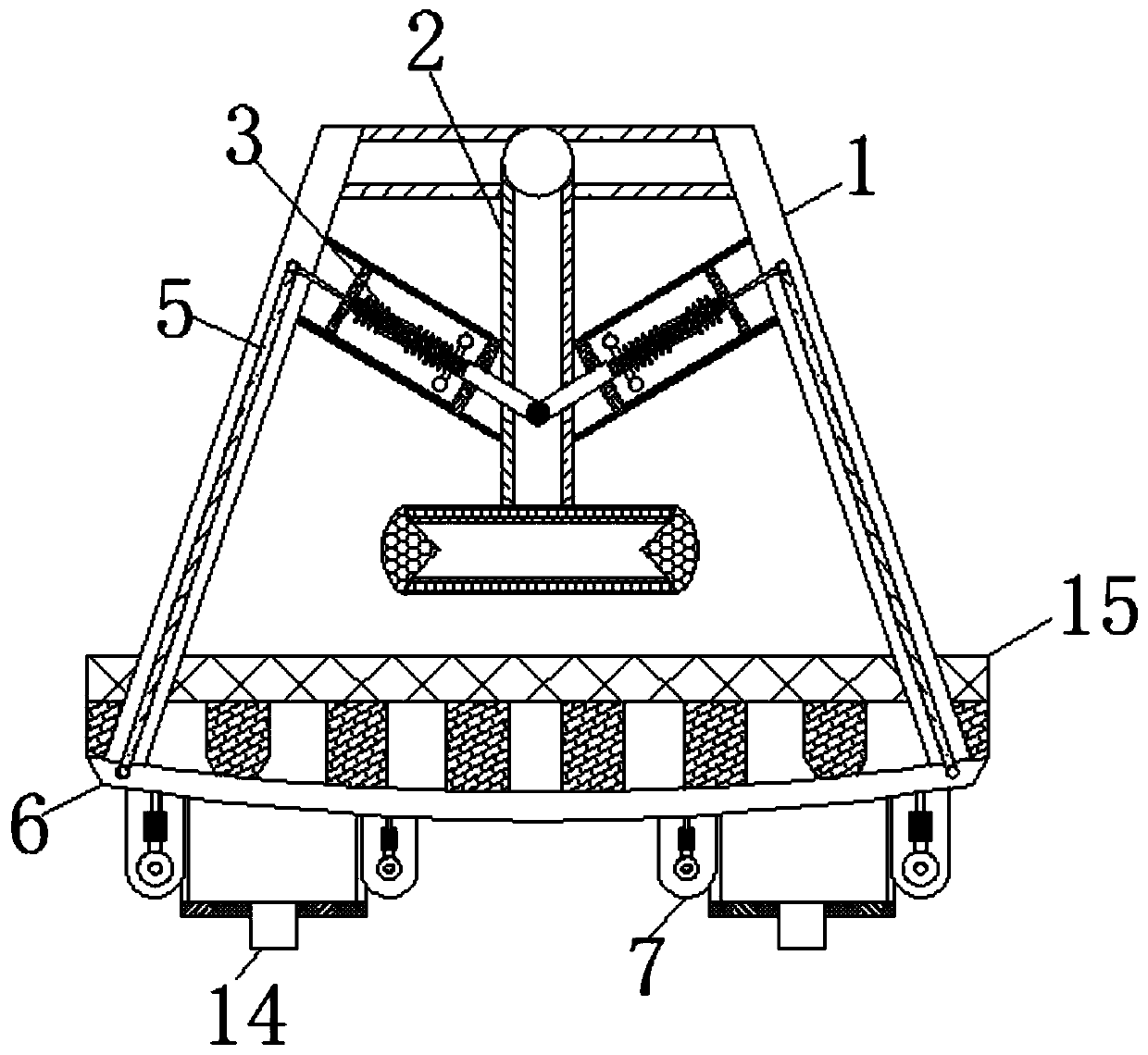

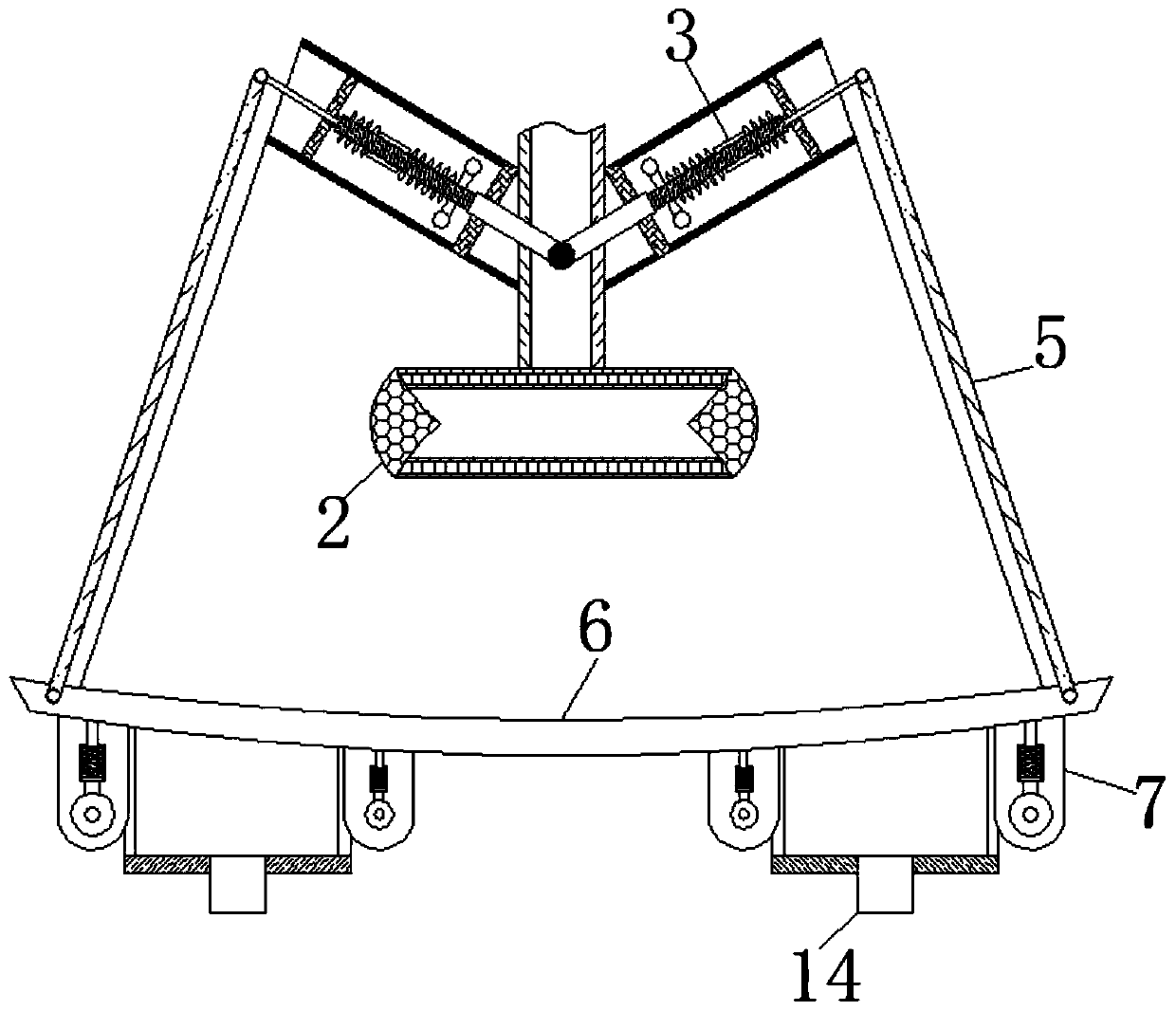

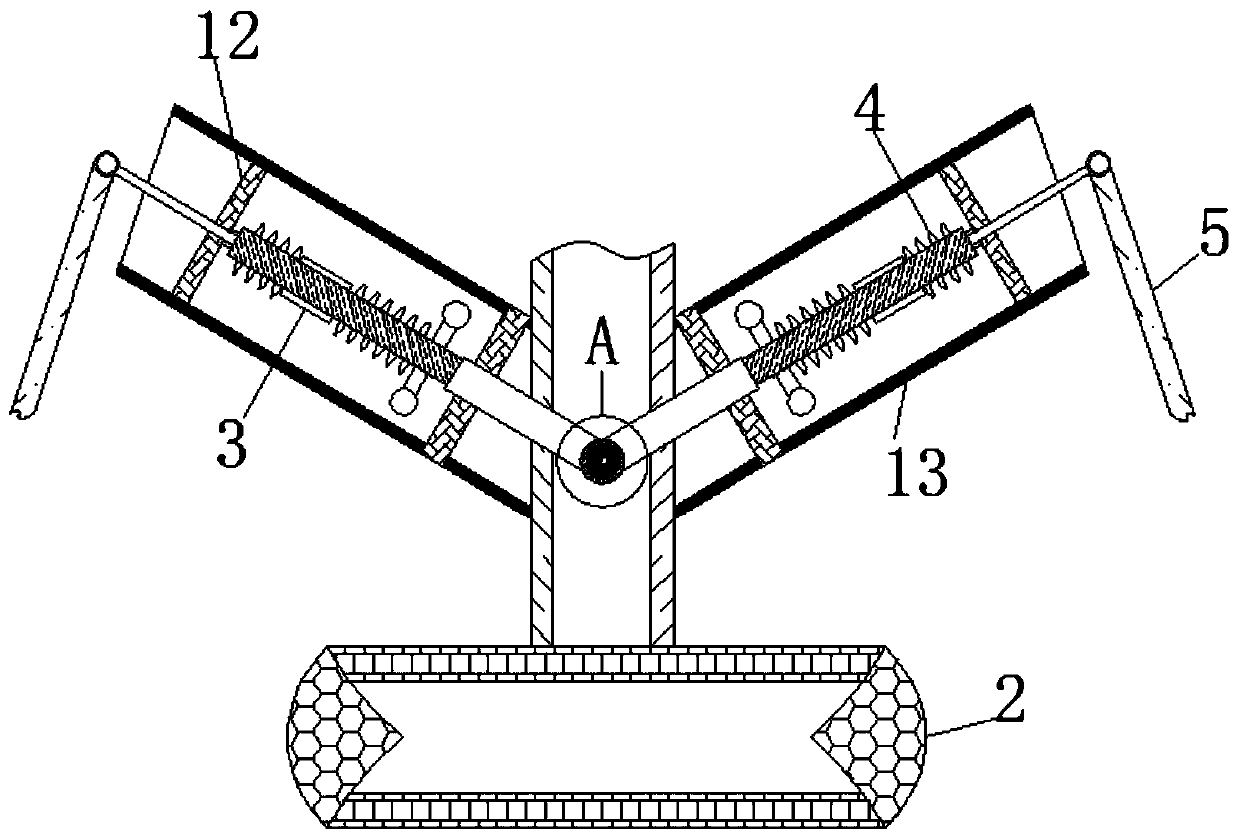

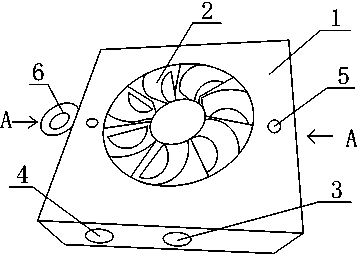

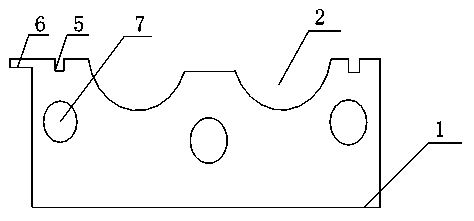

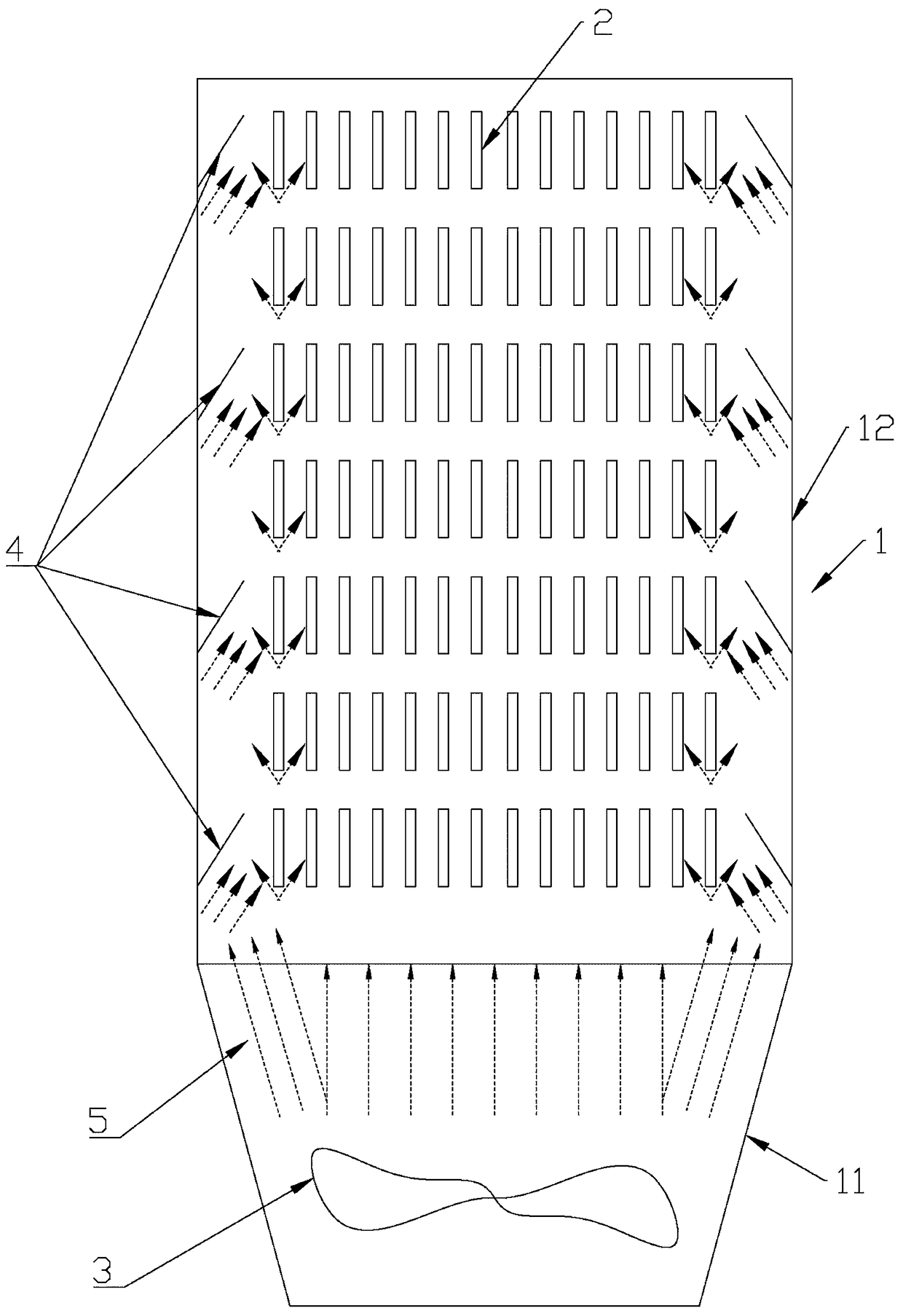

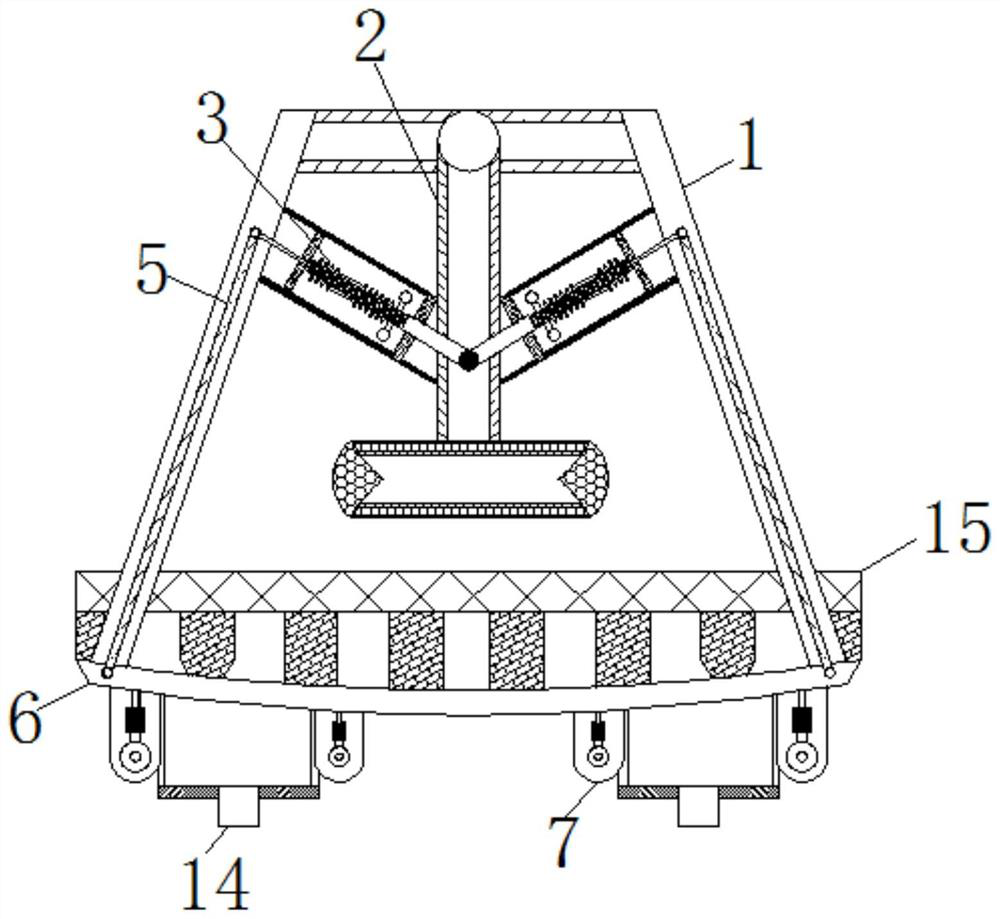

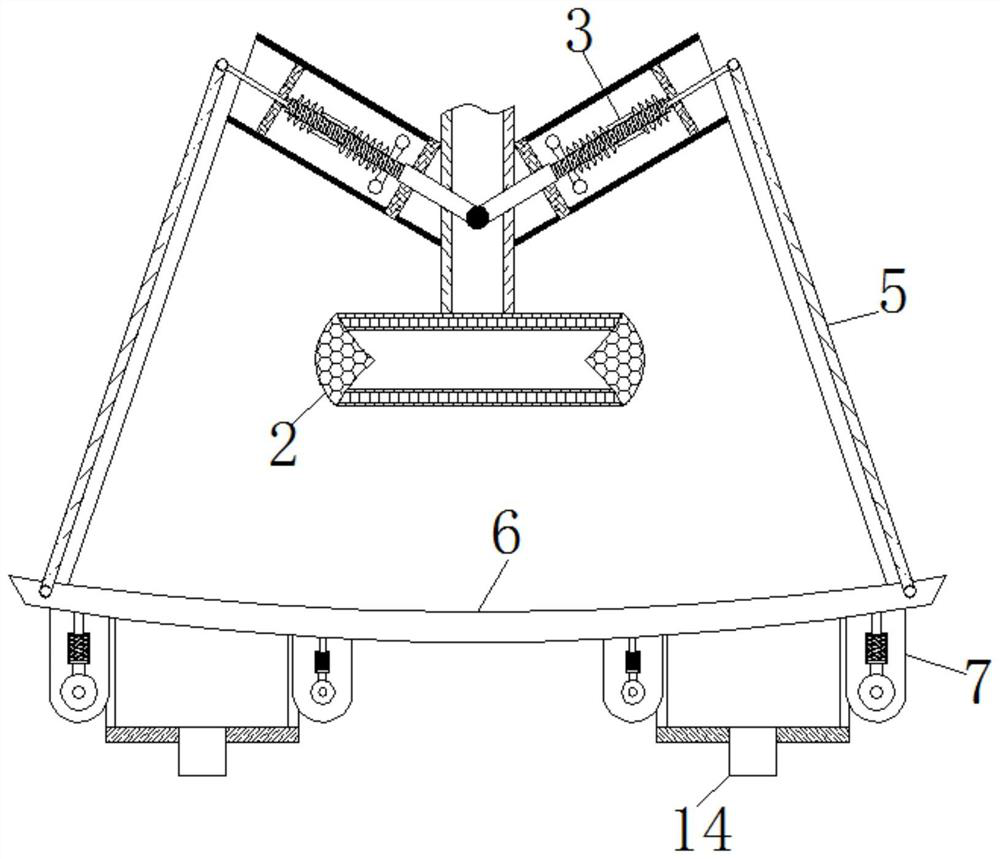

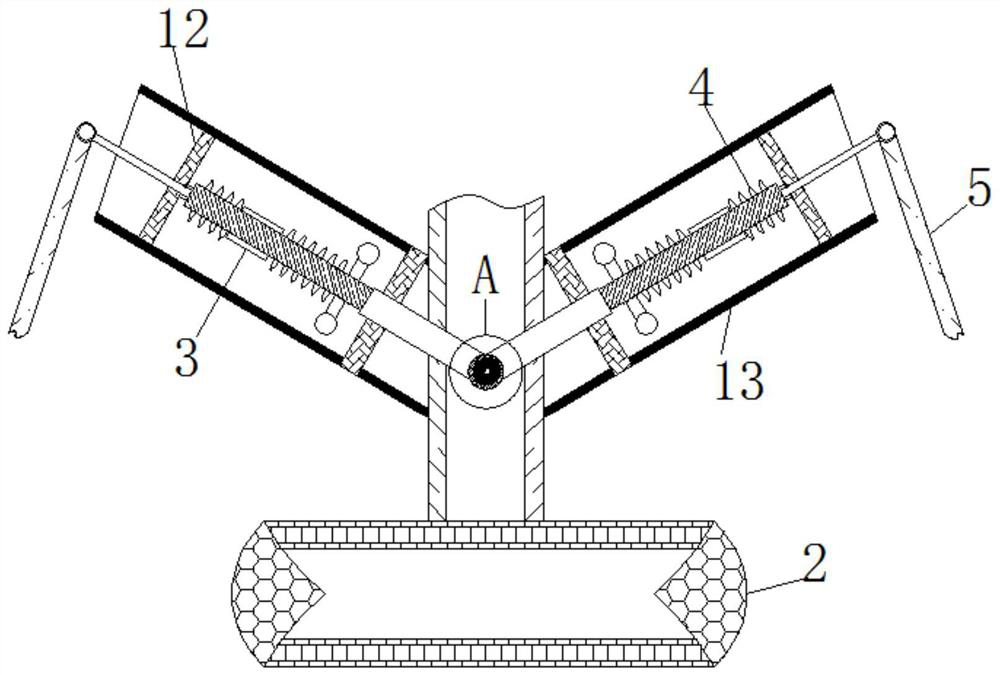

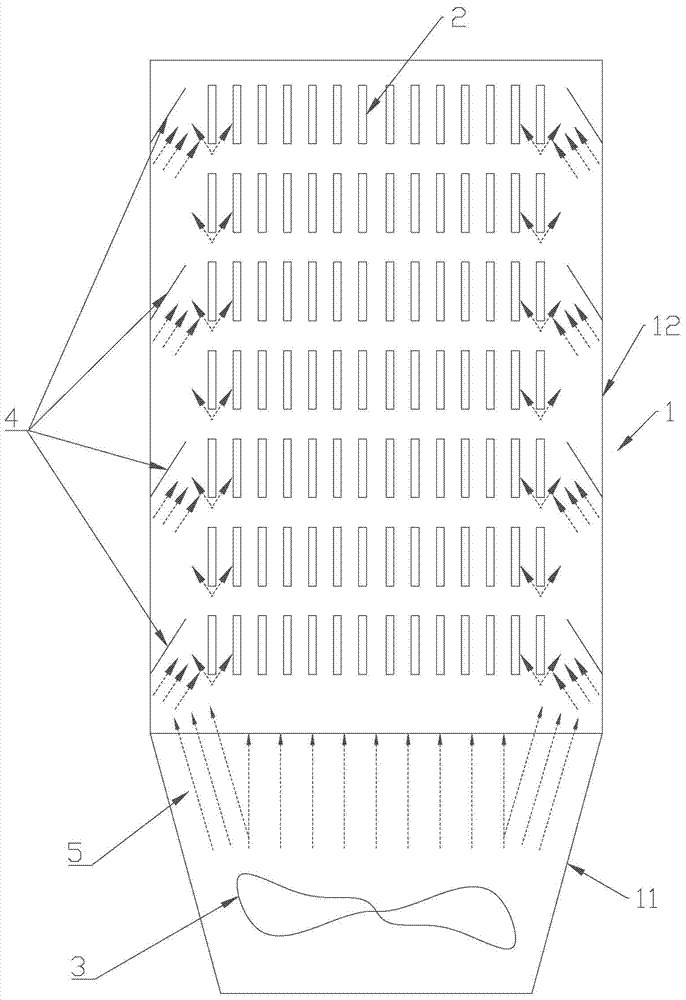

Winnowing pan type grain throwing machine

ActiveCN104310002AGood for taking awayTake away muchThrowing machinesAgriculture tools and machinesImpellerLow noise

The invention relates to a winnowing pan type grain throwing machine. The winnowing pan type grain throwing machine comprises a frame, a grain throwing hood, a throwing motor and an impeller. The impeller is arranged in the grain throwing hood which is arranged on the upper portion of the frame, bearing seats at two ends of the impeller are arranged on the frame respectively, a center shaft of the impeller is connected with an output shaft of the throwing motor through a coupler, and the center shaft, the coupler and the output shaft are coaxial. The grain throwing hood is provided with a feeding port and a discharging port, and blades of the impeller are bent plates. The winnowing pan type grain throwing machine has the advantages of small size, stability of grain throwing paths, low noise, detachability of parts, convenience in installation and maintenance, low cost and flexibility in use.

Owner:HENAN JINMING AUTOMATION EQUIP

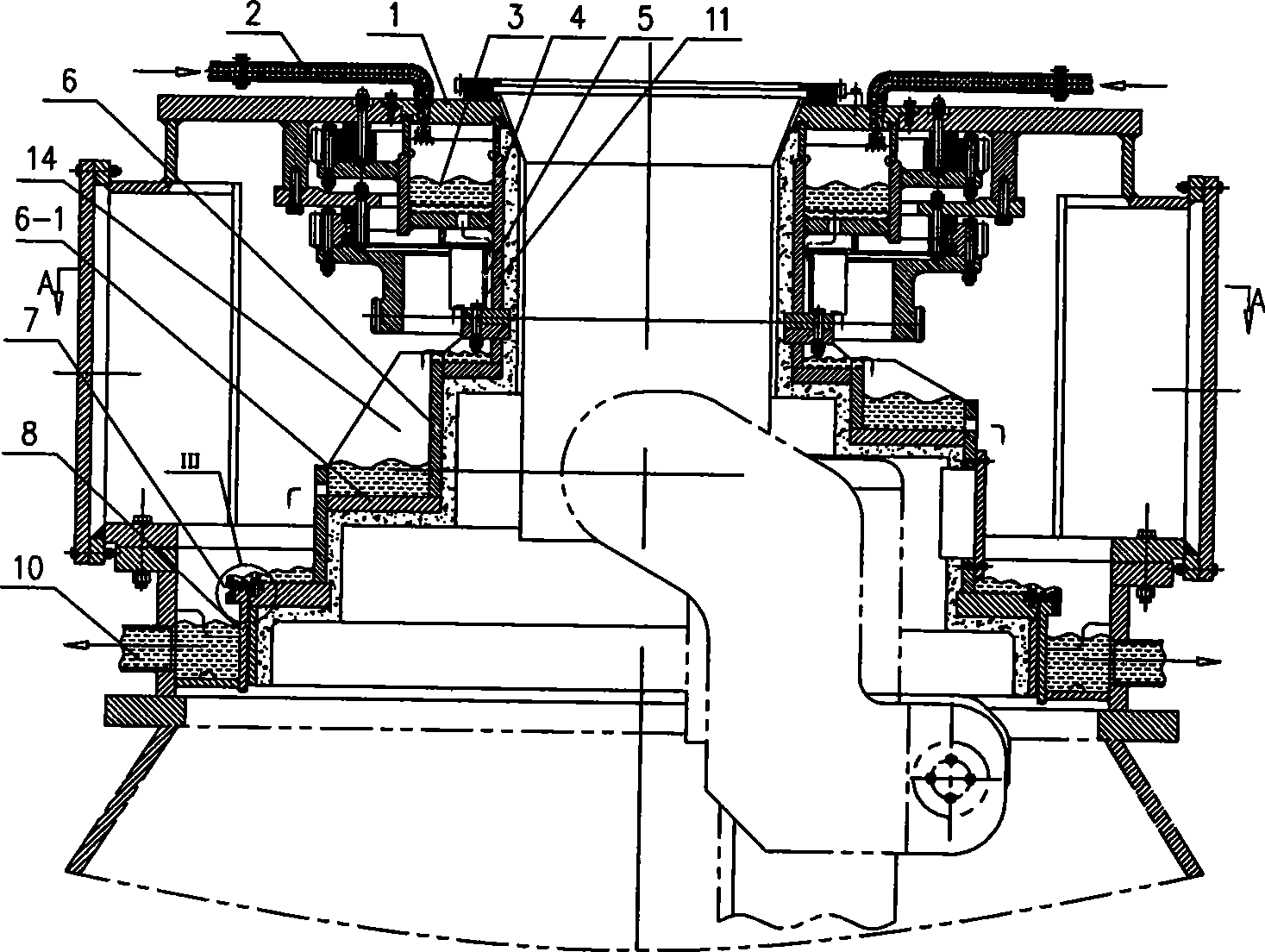

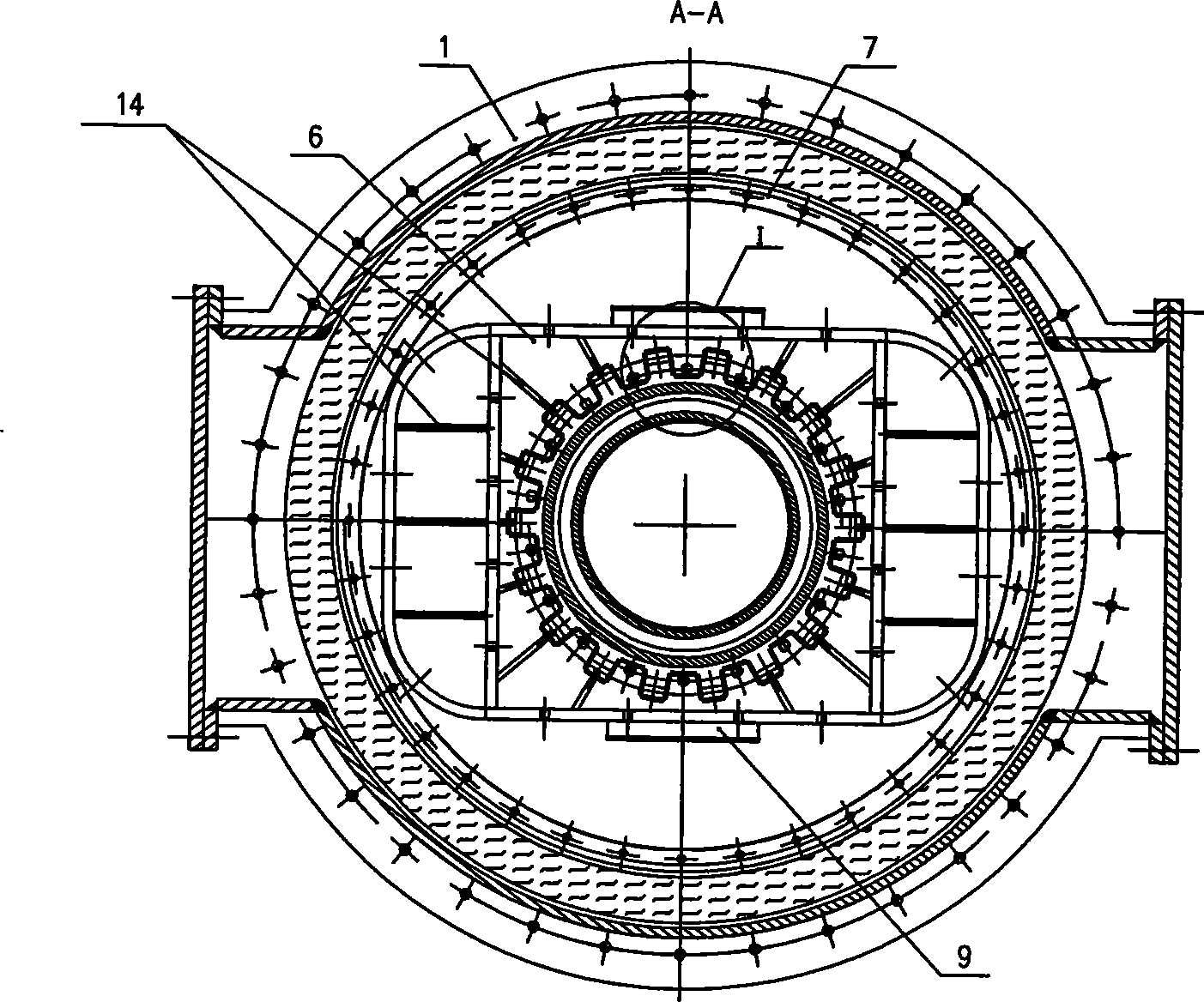

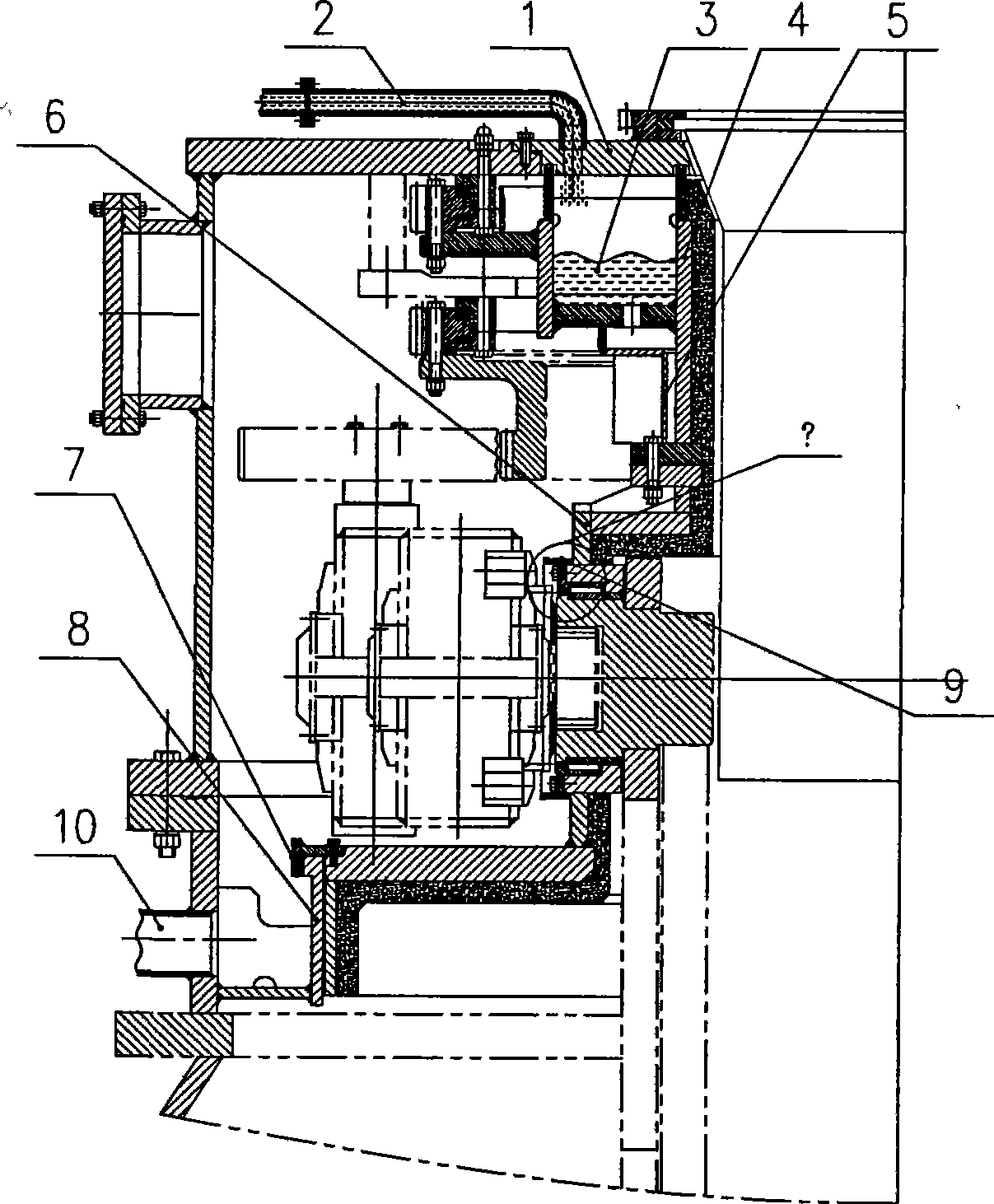

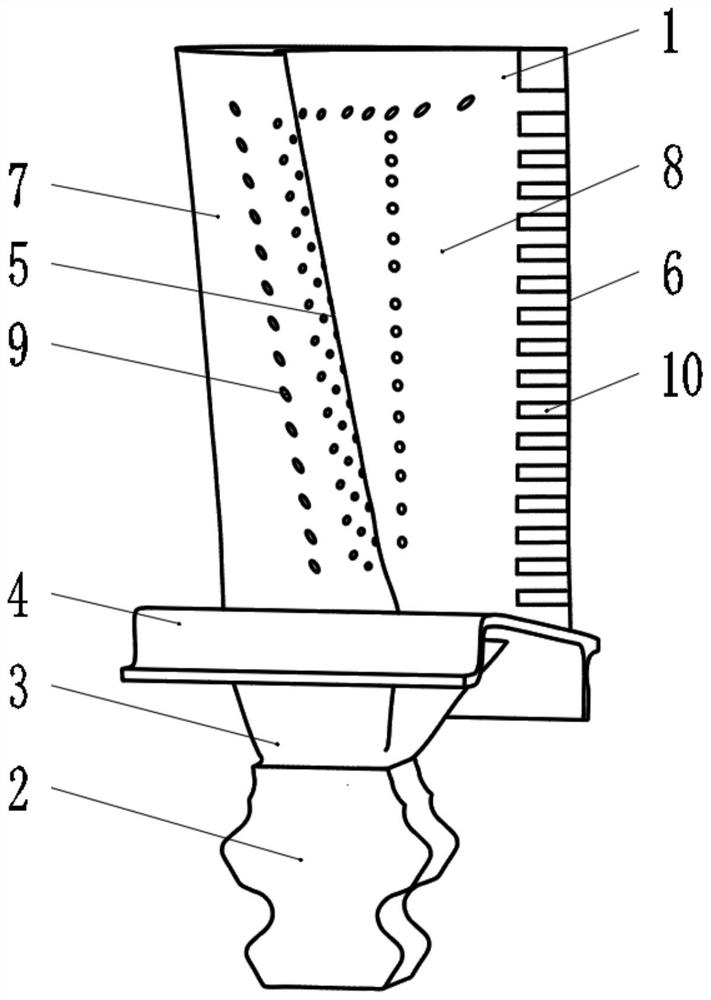

Water-cooling system for top distributor of blast furnace

InactiveCN101463400AImprove cooling effectSimple structureBell-and-hopper arrangementCooling effectEngineering

The invention relates to a water cooling system of an ironmaking furnace top distributing gear. The distributing gear comprises a rotary mechanism consisting of an upper rotary cylinder (4) and a lower rotary cylinder (6). At least one stage of platform (6-1) is arranged on the lower rotary cylinder (6). The water cooling system also comprises a water inlet pipe (2) and a water outlet pipe (10); the key of the water cooling system is that the water inlet pipe (2) penetrates through a distributing gear box (1) to be communicated with a rotary water tank (3) which is fixed at the rotary mechanism of the distributing gear. The water outlet pipe (10) is communicated with a fixed water tank (8) which is arranged at the outer side of the lower rotary cylinder (6) and is separated from the lower rotary cylinder (6). The lower part of the rotary water tank (3) is provided with a hole (3-1). The rotary water tank (3) is communicated with the fixed water tank (8) by the hole (3-1). The water cooling system has good cooling effect, convenient installation and maintenance and long service life and can be applied to various distributing gears of ironmaking furnace engineering.

Owner:CISDI ENG CO LTD

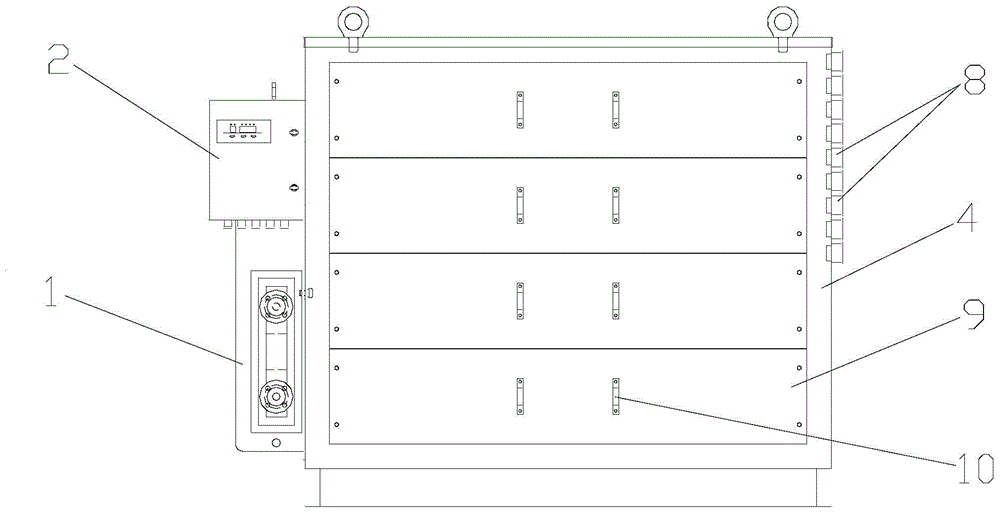

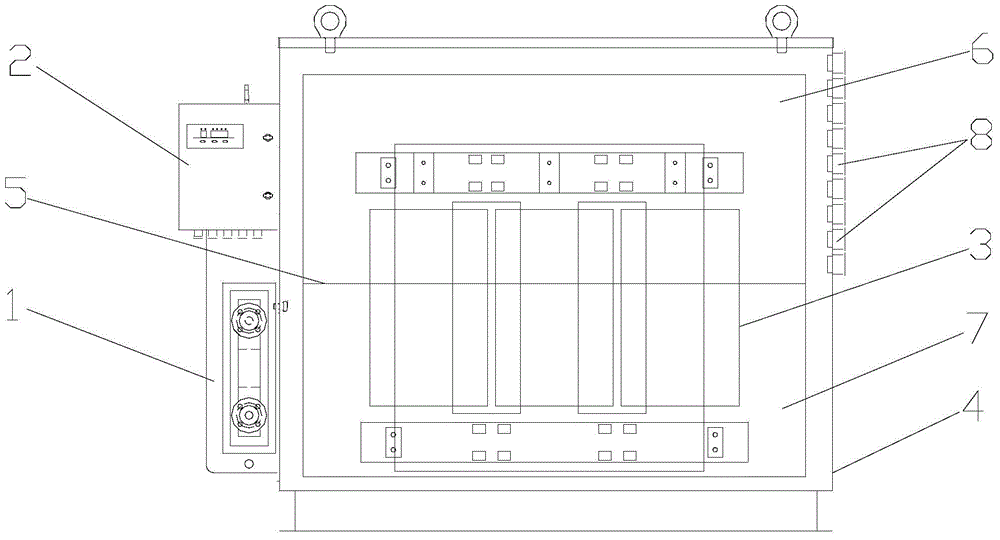

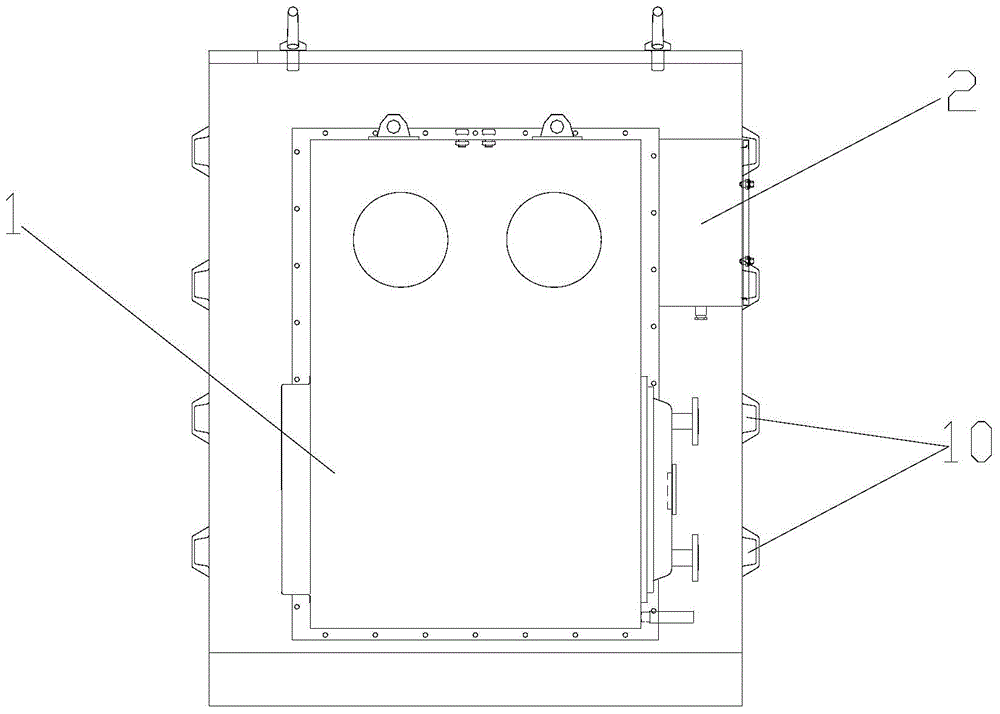

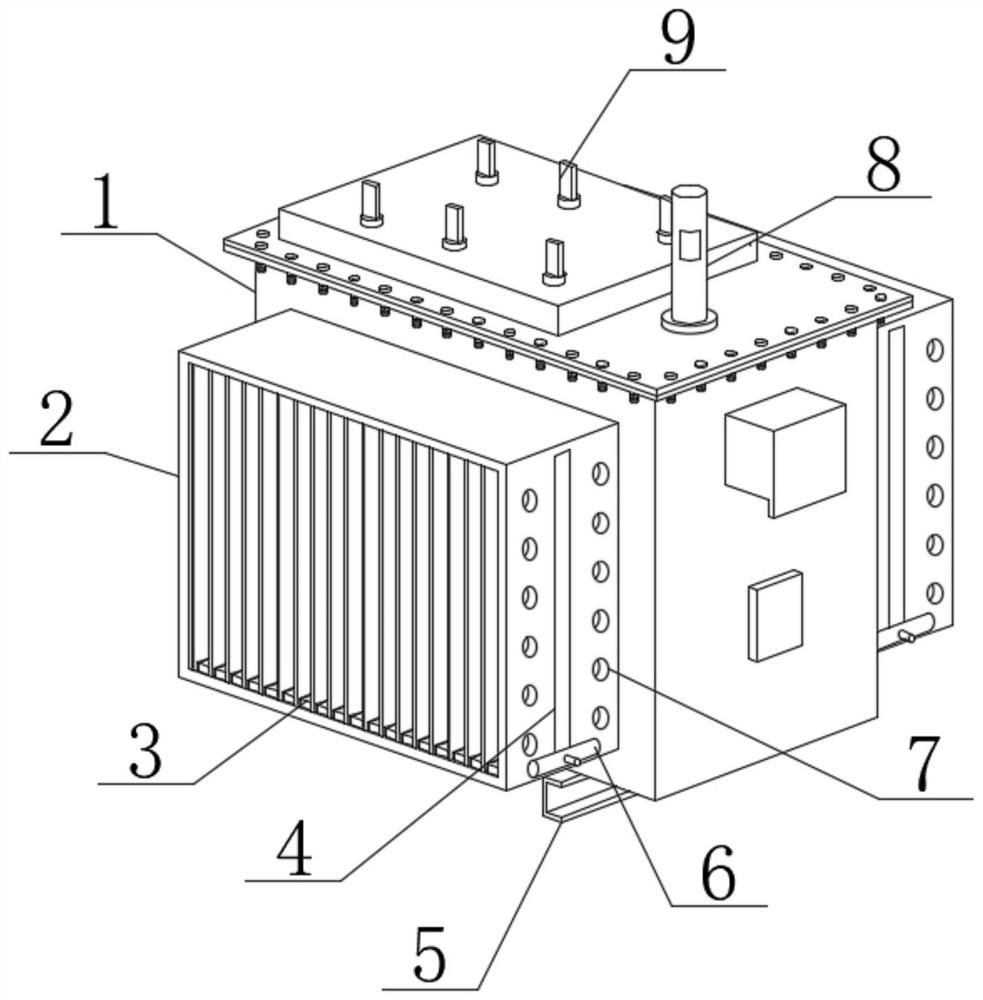

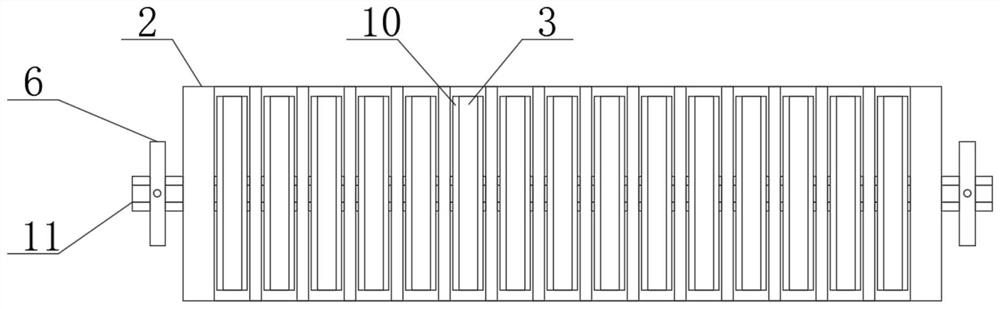

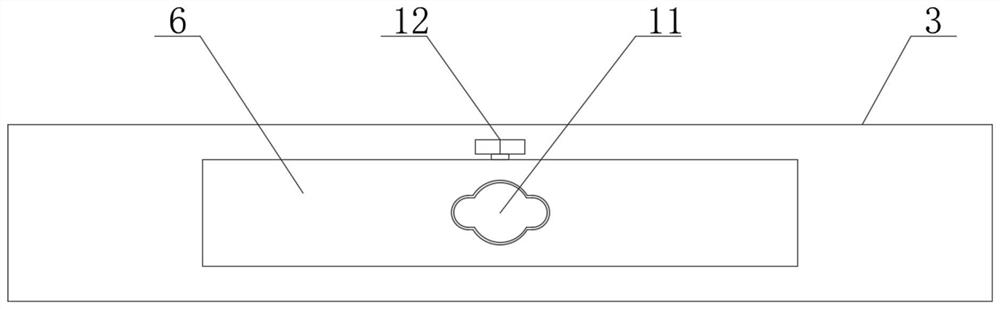

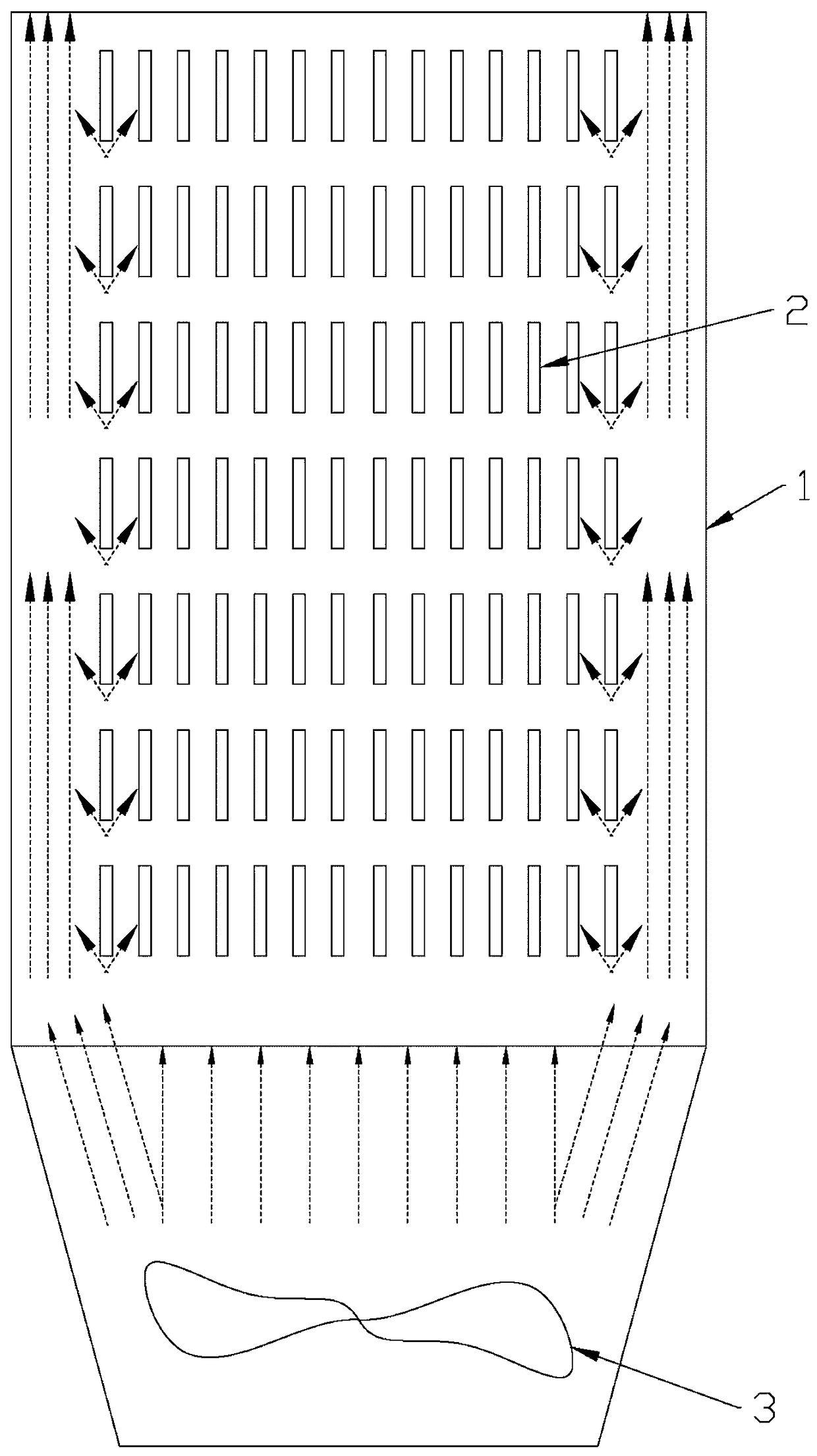

Air-cooled and water-cooled transformer for ship

InactiveCN104409193AReduce temperature riseReduce volumeTransformers/inductances coolingWater circulationWater pipe

The invention discloses an air-cooled and water-cooled transformer for a ship. The transformer comprises an air-cooling and water-cooling device, a control box, a transformer body and a frame box, wherein the transformer body is assembled in the frame box, a horizontal separation plate is arranged in the center inside the frame box to divide the frame box into an upper separation layer and a lower separation layer, the air-cooling and water-cooling device is arranged outside the frame box and comprises a fan and a water pipe, the control box is arranged beside the air-cooling and water-cooling device and controls on and off of the fan, and a plurality of stuffing boxes are arranged on both the frame box and the control box. The transformer has the advantages that by the aid of the air-cooling and water-cooling device, the temperature rise of the transformer is effectively reduced, and heat produced by the transformer is taken away through water circulation, so that the transformer is cooled, the effect is good, the limitation of a transformer winding to coil specifications can be reduced, and requirements of some special environments with ventilation limitations are met.

Owner:镇江船舶电器有限责任公司

High-speed motor strong air cooling structure

InactiveCN103746514AImprove cooling effectTo achieve the purpose of ventilation and heat dissipationCooling/ventillation arrangementSupports/enclosures/casingsElectric machineMachine

The invention aims at solving problems that existing high-speed motors are poor in heat-radiating effect. The invention discloses a high-speed motor strong air cooling structure comprising a machine base. The machine base is internally provided with a stator and a rotor which is opposite to the stator. Two sides of the stator and the rotor are winding end sides. The high-speed motor strong air cooling structure also comprises an air-blower. The machine base is provided with an air inlet, air channels which pass through the winding end sides and an air outlet which is communicated with the air channels. The air-blower is communicated with the air inlet on the machine base. An air-blower cooling structure is adopted so that the high-speed motor is great in the heat-radiating effect.

Owner:CHONGQING ELECTRIC MACHINE FEDERATION

Utensil suitable for collecting wax liquor

InactiveCN105588093AAvoid influenceLarge horizontal areaCandle holdersDispersed particle filtrationWaxAir pump

The invention discloses a utensil suitable for collecting wax liquor. The utensil comprises a candleholder body, an air blow pipe, an air suction pipe and a filter element. The candleholder body is of a cavity structure. A micro air pump is arranged inside the candleholder body. A through hole A and a through hole B which communicate with the cavity in the candleholder body are formed in the top end of the candleholder body. The through hole A and the through hole B are symmetrically arranged using the midpoint on the top of the candleholder body as the center. The air blow pipe communicates with the through hole A, and the bottom end of the air blow pipe is connected with an air outlet of the micro air pump. The air suction pipe communicates with the through hole B, and the bottom of the air suction pipe is connected with an air inlet of the micro air pump. The top end of the air blow pipe and the top end of the air suction pipe are oppositely arranged. The filter element is arranged in the air suction pipe. The utensil further comprises a fixing needle. Supporting legs which expand outwards are arranged at the bottom of the fixing needle, and the fixing needle is placed at the center position of the top of the candleholder body through the supporting legs. A wax liquor containing cavity is formed in the center position of the top of the candleholder body, and is located under the fixing needle. Wax liquor generated by melting candles flows into the wax liquor containing cavity to be stored for secondary utilization.

Owner:曾郇

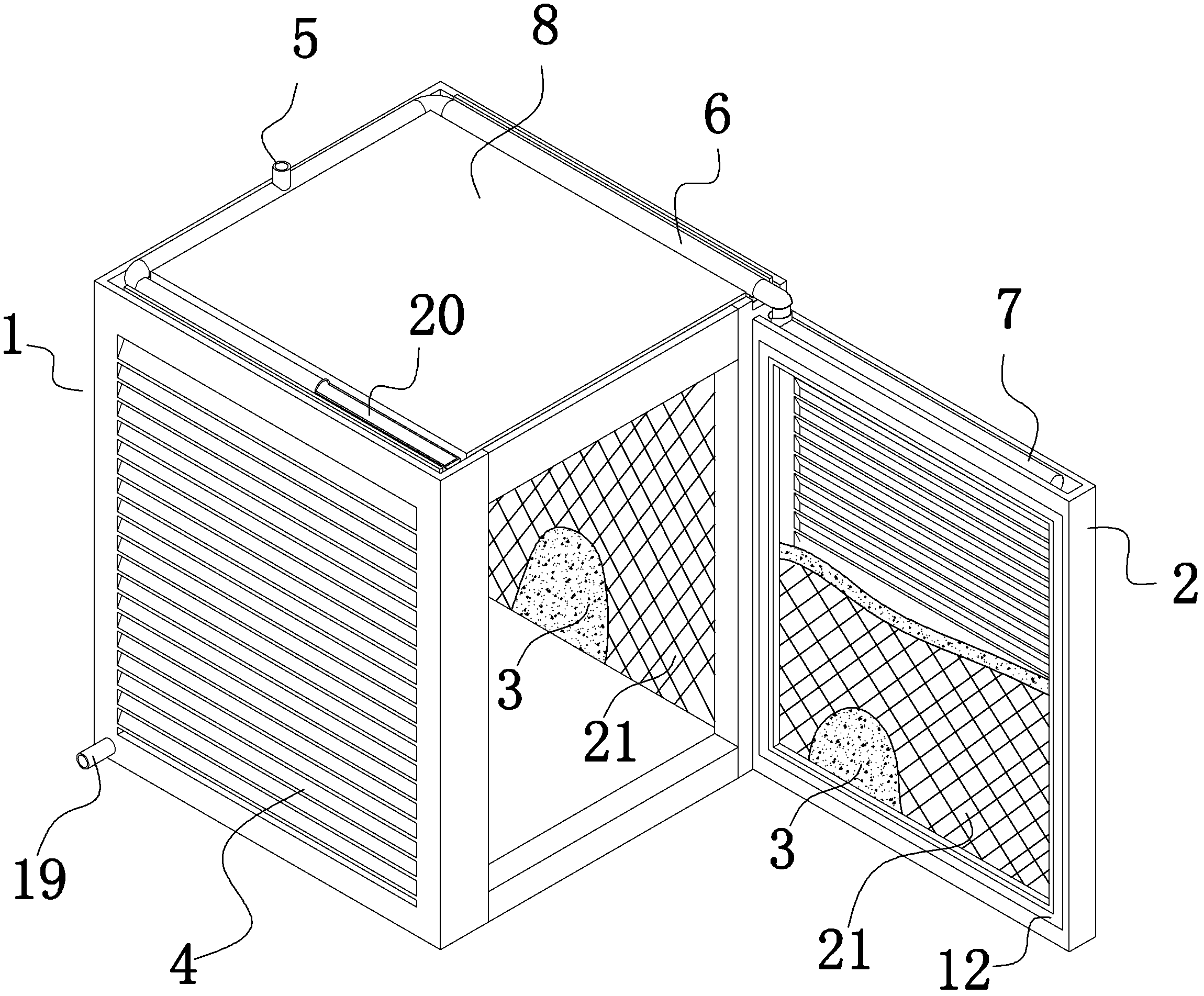

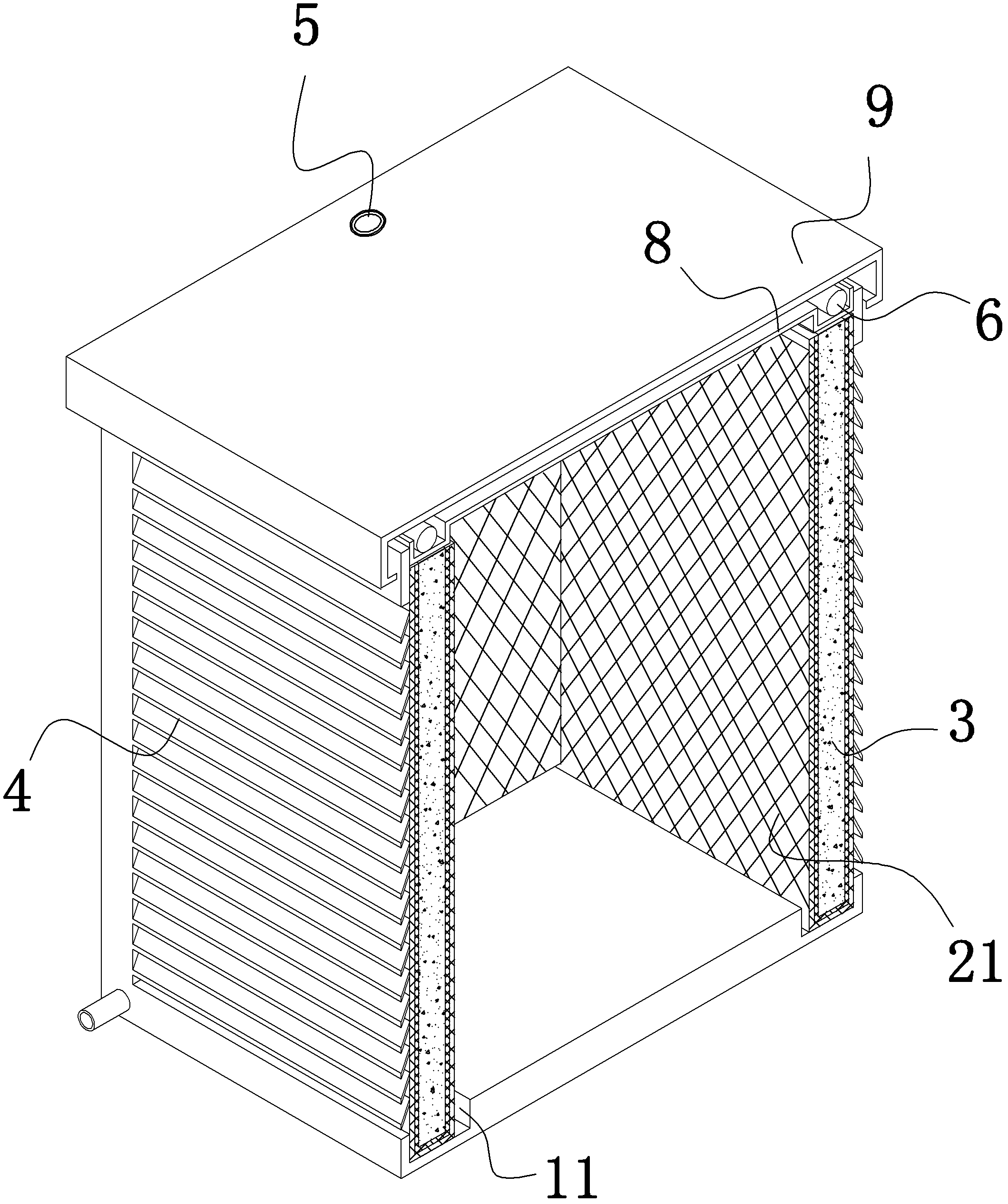

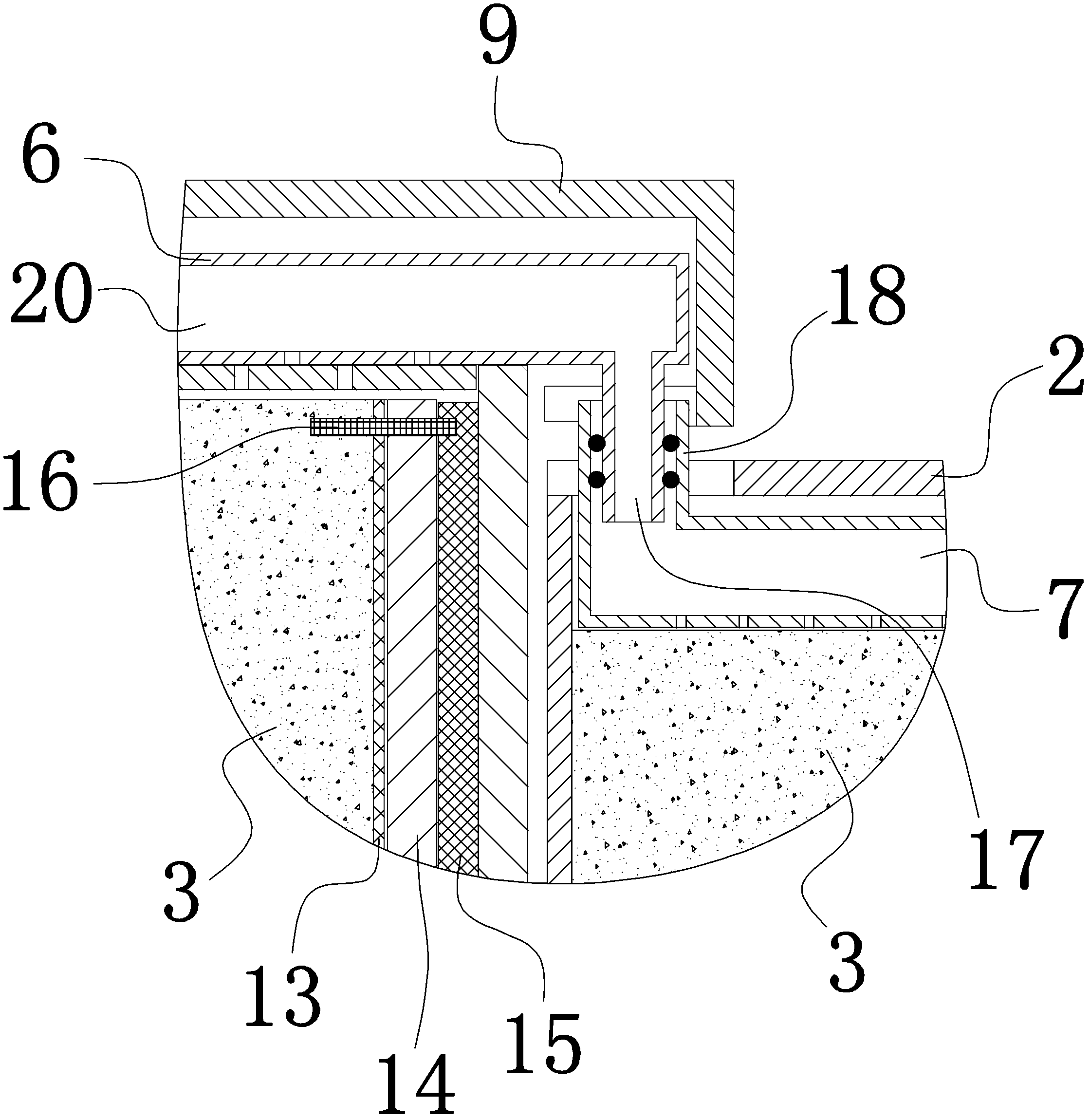

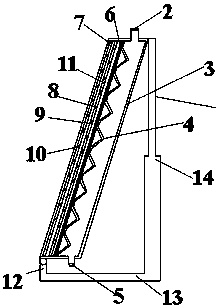

Preservation cabinet

The invention discloses a preservation cabinet, and aims to provide a non-power-consumption preservation cabinet which has the advantages that external heat can be effectively obstructed, the water evaporation efficiency is increased, more heat is brought away and the humidity in the cabinet is increased so as to improve the preservation effect. The preservation cabinet comprises ventilation holes or louver ventilation structures, a capillary material layer, a trough and a waterway passage, wherein the ventilation holes or the louver ventilation structures are formed in side faces of the preservation cabinet; the capillary material layer is arranged on the side wall of a storage space of the preservation cabinet in the way of extending from the bottom surface of the preservation cabinet to the top surface; the trough is formed in the bottom surface of the storage space of the preservation cabinet in the way of extending along the edge of the bottom surface of the storage space of the preservation cabinet; the bottom of the capillary material layer extends into the trough; the waterway passage is arranged in a top cover of the preservation cabinet in the way of extending along the edge of the top surface of the storage space of the preservation cabinet; and the lower part of the waterway passage is provided with a plurality of fine meshes for communicating the capillary material layer with the waterway passage.

Owner:许炳才

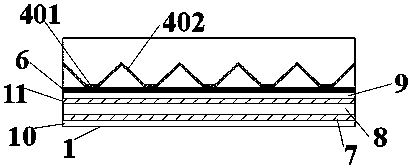

Novel solar panel

InactiveCN107742657AIncrease cooling areaTake away muchPhotovoltaic energy generationSemiconductor devicesHeat conductingArchitectural engineering

The invention provides a novel solar panel. The solar panel includes a solar panel body, the bottom surface of the solar panel body is fixedly provided with a heat conducting sheet connected with a heat dissipation device, the bottom surface of the solar panel body is provided with a sealing cavity, the lower end of the sealing cavity is provided with a liquid inlet pipe, the upper end of the sealing cavity is provided with a liquid draining pipe, a vertical fixing column is arranged on the bottom of the lower end of the solar panel body and rotatably connected with the solar panel body, a vertical retractable column is fixed on the back surface of the upper end of the solar panel body, the upper end of the retractable column is rotatably connected with the solar panel body, and the vertical fixing column is fixedly connected with the lower end of the retractable column through a connecting column. By installing the heat conducting sheet and the heat dissipation device on the bottom ofthe solar panel body, the heat can be transmitted to the water in a cavity, not only can fast cooling be achieved, but also the heat can be recycled, the effects of saving the energy and protecting environment are achieved, and the fixation is much sturdier.

Owner:孝感正茂建材有限公司

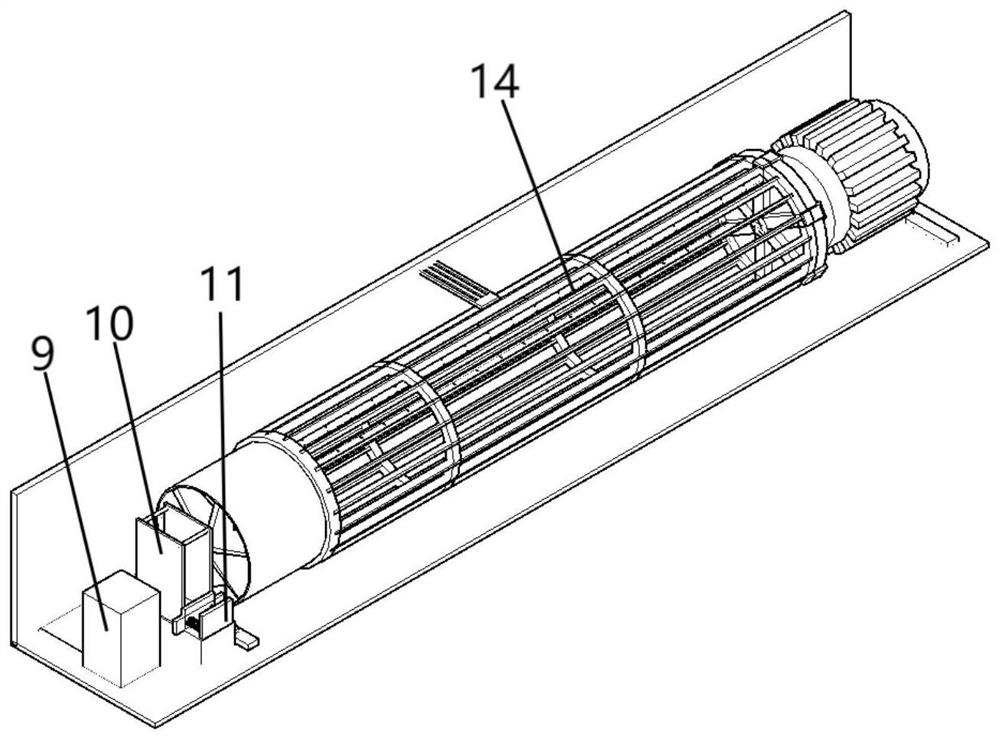

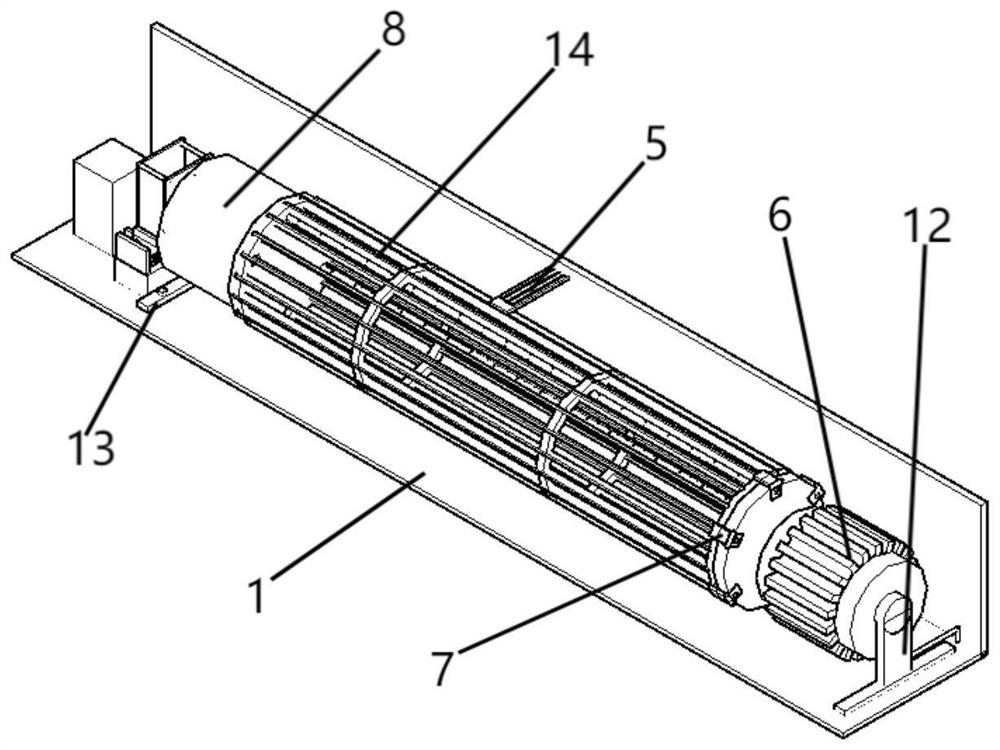

A bucket type grain throwing machine

ActiveCN104310002BGood for taking awayTake away muchThrowing machinesAgriculture tools and machinesImpellerLow noise

The invention relates to a winnowing pan type grain throwing machine. The winnowing pan type grain throwing machine comprises a frame, a grain throwing hood, a throwing motor and an impeller. The impeller is arranged in the grain throwing hood which is arranged on the upper portion of the frame, bearing seats at two ends of the impeller are arranged on the frame respectively, a center shaft of the impeller is connected with an output shaft of the throwing motor through a coupler, and the center shaft, the coupler and the output shaft are coaxial. The grain throwing hood is provided with a feeding port and a discharging port, and blades of the impeller are bent plates. The winnowing pan type grain throwing machine has the advantages of small size, stability of grain throwing paths, low noise, detachability of parts, convenience in installation and maintenance, low cost and flexibility in use.

Owner:HENAN JINMING AUTOMATION EQUIP

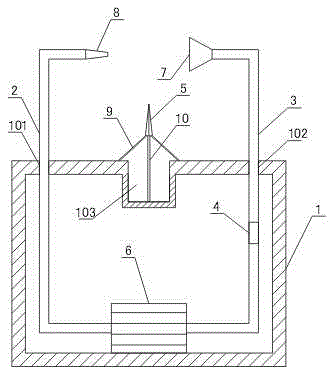

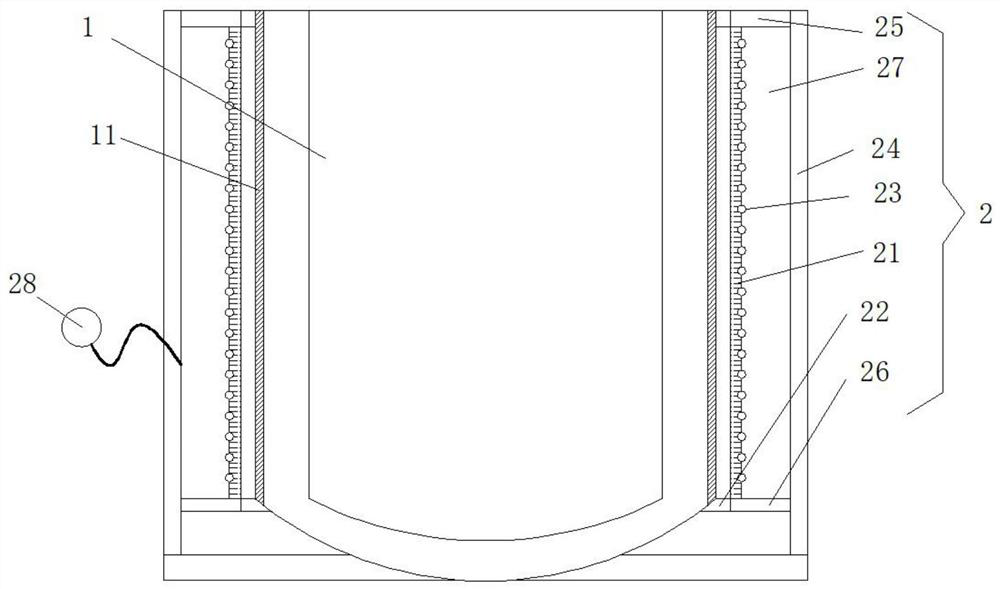

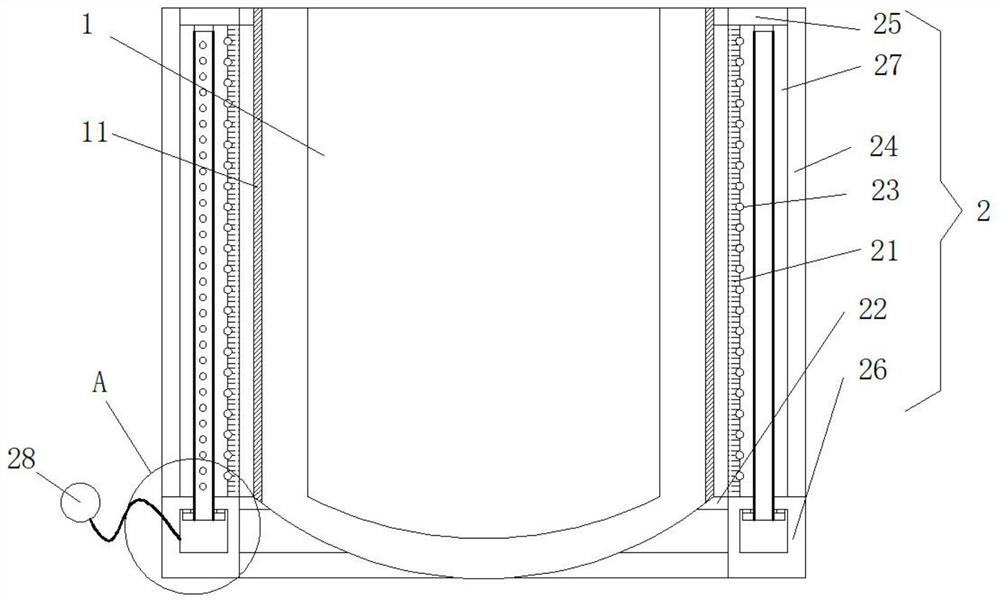

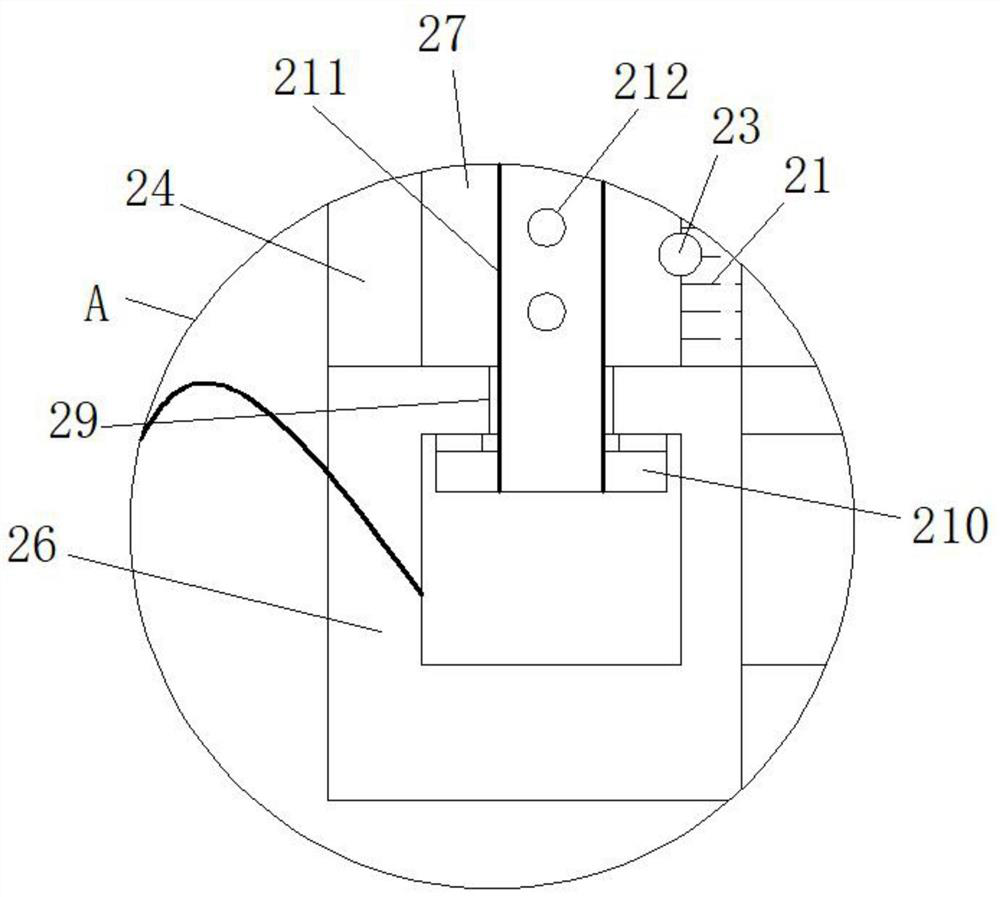

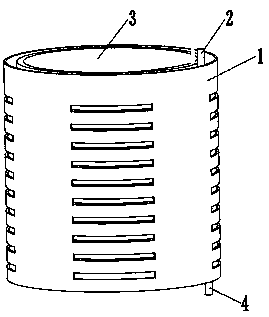

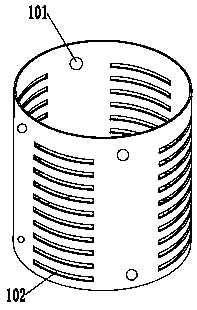

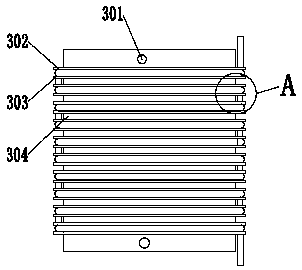

Induction heating furnace with induction coil clearance type heat dissipation

ActiveCN112113420AMeet the needs of long working hoursAvoid overall overheatingCoil arrangementsCrucible furnacesAir pumpEngineering

The invention provides an induction heating furnace with induction coil clearance type heat dissipation. The induction heating furnace with induction coil clearance type heat dissipation is characterized in that a coil mounting mechanism is arranged outside a furnace pipe, and comprises an inner cylinder; the furnace pipe is coaxially sleeved with the inner cylinder; a plurality of connecting blocks are fixedly connected to the inner wall of the inner cylinder, and are further fixedly connected with the outer wall of the furnace pipe; two ends of the inner side of the inner cylinder are open;and a plurality of through holes are uniformly formed in the cylinder wall of the inner cylinder. An induction coil is wound on the outer wall of the inner cylinder; adjacent coils on the induction coil are not in contact; the inner cylinder is externally coaxially sleeved with an outer cylinder; a first sealing ring and a second sealing ring are arranged at the top end and the bottom end betweenthe outer cylinder and the inner cylinder respectively, and seal the top end and the bottom end of the part between the outer cylinder and the inner cylinder respectively; a cavity is formed between the outer cylinder and the inner cylinder, and communicates with an air pump through a pipeline; and the air pump pumps air into the cavity. According to the technical scheme, active heat dissipation is adopted for the induction coil, so that the requirement for long-time work can be met.

Owner:安徽宏达电炉科技有限公司

Dual ultrasonic heat pipe cooling device

InactiveCN106767067BImprove cooling efficiencyPromote refluxIndirect heat exchangersHeat transfer modificationElectricityUltrasonic sensor

The invention discloses a double-ultrasonic heat pipe cooling device, which belongs to the technical field of refrigeration and heat exchange. The double ultrasonic heat pipe cooling device includes a heat pipe, and the heat pipe includes a hot end and a condensation end. The heat pipe is provided with a piezoelectric ultrasonic transducer at the hot end and the condensation end respectively, and the piezoelectric ultrasonic transducer is connected between the hot end and the condensation end. Ultrasonic waves of different frequencies are generated at the hot end, the frequency range of the ultrasonic wave at the hot end is 20kHz-40kHz, and the frequency range of the ultrasonic wave at the condensing end is 400kHz-700kHz; the piezoelectric ultrasonic transducer includes piezoelectric ceramics and vibrators connected with piezoelectric ceramics. The invention can promote the flow of liquid and gas in the heat pipe, and improves the heat dissipation efficiency.

Owner:SHANDONG UNIV +1

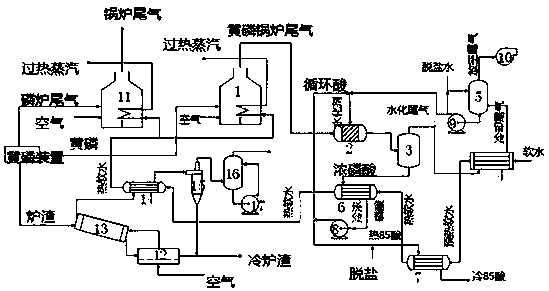

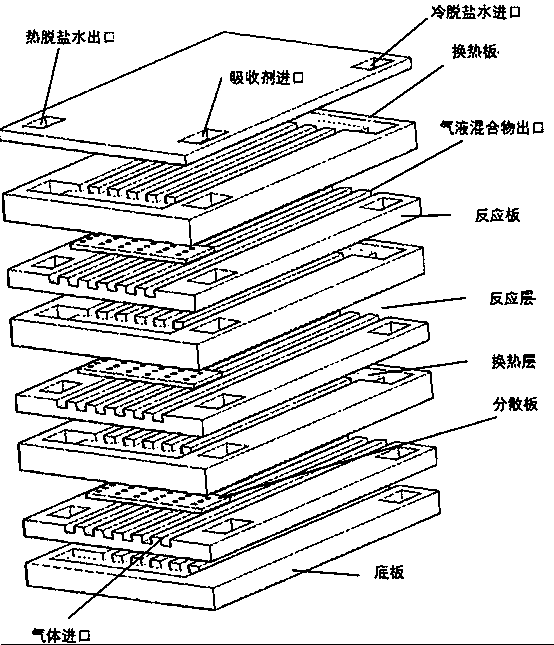

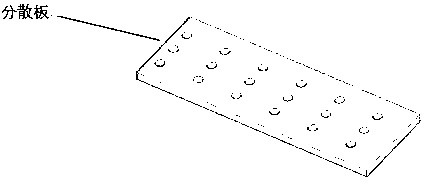

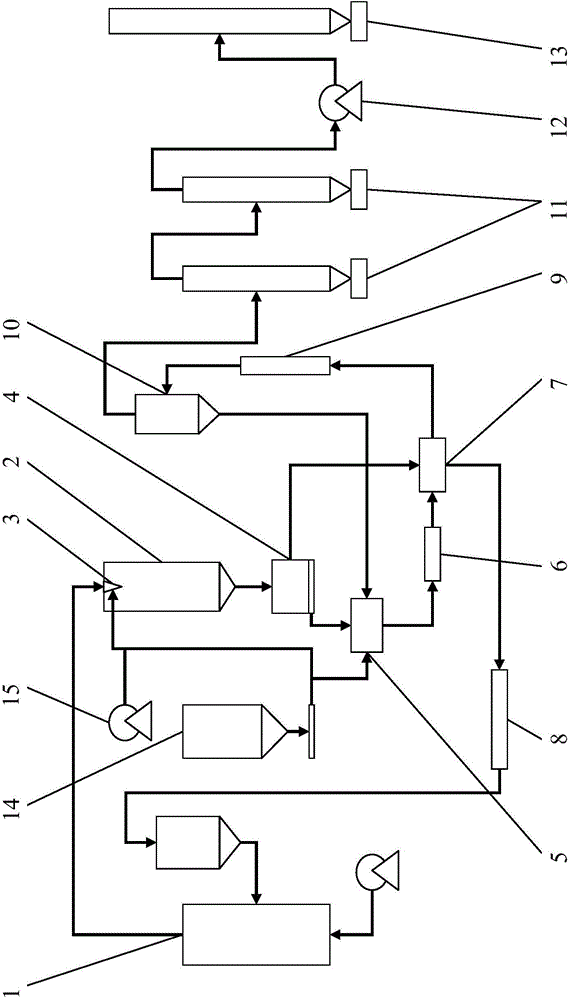

A method and device for combined thermal energy recovery of thermal phosphoric acid and polyphosphoric acid micro-absorption

ActiveCN107200314BEfficient recyclingReduce manufacturing costEnergy inputCombustion technology mitigationRecovery methodSlag

The invention discloses a heat energy recovery method for combining heat-process phosphoric acid and polyphosphoric acid micro absorption and a device thereof. According to the method, a micro absorption heat exchanger is used for recovering heat of reaction heat of phosphorus pentoxide and water; the heat of furnace slag is recovered through a furnace slag heat recovery device; the recovered heat of the reaction heat and the heat of the furnace slag are simultaneously connected into an air heat exchanger to prepare hot soft water; the hot soft ware is conveyed to a yellow phosphorus furnace and a phosphorus furnace tail gas boiler through pipelines for overheating steam; through combining the reaction heat, the furnace slag heat, the byproduct tail gas combustion heat and the yellow phosphorus combustion heat, the efficient recovery and utilization of the heat energy is realized. The goals of producing heat-process phosphoric acid or polyphosphoric acid by low energy consumption and recovering the combustion heat of the byproduct tail gas of the yellow phosphorus, the combustion heat of the yellow phosphorus, the reaction heat of phosphorus pentoxide and water, the solidification heat and the sensible heat of the furnace slag at the same time can be achieved; the recovery efficiency is high; the energy sources can be favorably saved; the production cost is effectively reduced.

Owner:贵州东晟捷能科技有限公司

Drying tunnel used for heating and dehumidifying water paint

PendingCN107670936AIncrease temperatureFast curingPretreated surfacesCoatingsInterior spaceWater based

The invention discloses a drying tunnel used for heating and dehumidifying water paint. The drying tunnel comprises a drying tunnel frame. Round shafts are rotatably mounted at the two ends of the drying tunnel frame, and the two round shafts are wrapped with the same stainless steel wire mesh. The temperature of heated substances is increased, the compression dewatering and dehumidifying functions are achieved in the internal space of a liner of the whole drying tunnel, and heating and dehumidifying are combined, so that water is evaporated into mist rapidly, and water is extracted rapidly bymeans of the suction force of a centrifugal fan in a dehumidifier; a paint film is reserved, the paint film is heated at a certain temperature and then solidified into a film rapidly, and thus an effective paint film is formed in the surface of a product; air is heated, so that the relative moisture content of air is decreased and kept being about 25% (the higher the temperature of air is, the higher the saturated moisture content of air is), and thus more steam can be taken away when air passes through the surfaces of the dried substances; and the contact area between the heated substances and flow air is enlarged, and heat in exhausted air is fully utilized.

Owner:湖南匡沐环保科技有限公司

Water-cooled motor casing

PendingCN108448802APlay a protective effectAvoid position shiftSupports/enclosures/casingsWater pipeMultiple layer

The invention discloses a water-cooled motor casing. The outer side of the motor casing is wound with a water pipe for cooling, the motor casing comprises a water-cooled protective shell and an innershell, multiple layers of protection plates are arranged at the outer side of the inner shell, the water pipe is wound among the protection plates, a water inlet pipe is arranged at the upper end of the motor casing, a water outlet pipe is arranged at the lower end of the motor casing, both the water inlet pipe and the water outlet pipe are connected with the water pipe, the water-cooled protective shell is arranged at the outer side of the inner shell, and the water-cooled protective shell and the inner shell are connected through bolts.

Owner:张健铭

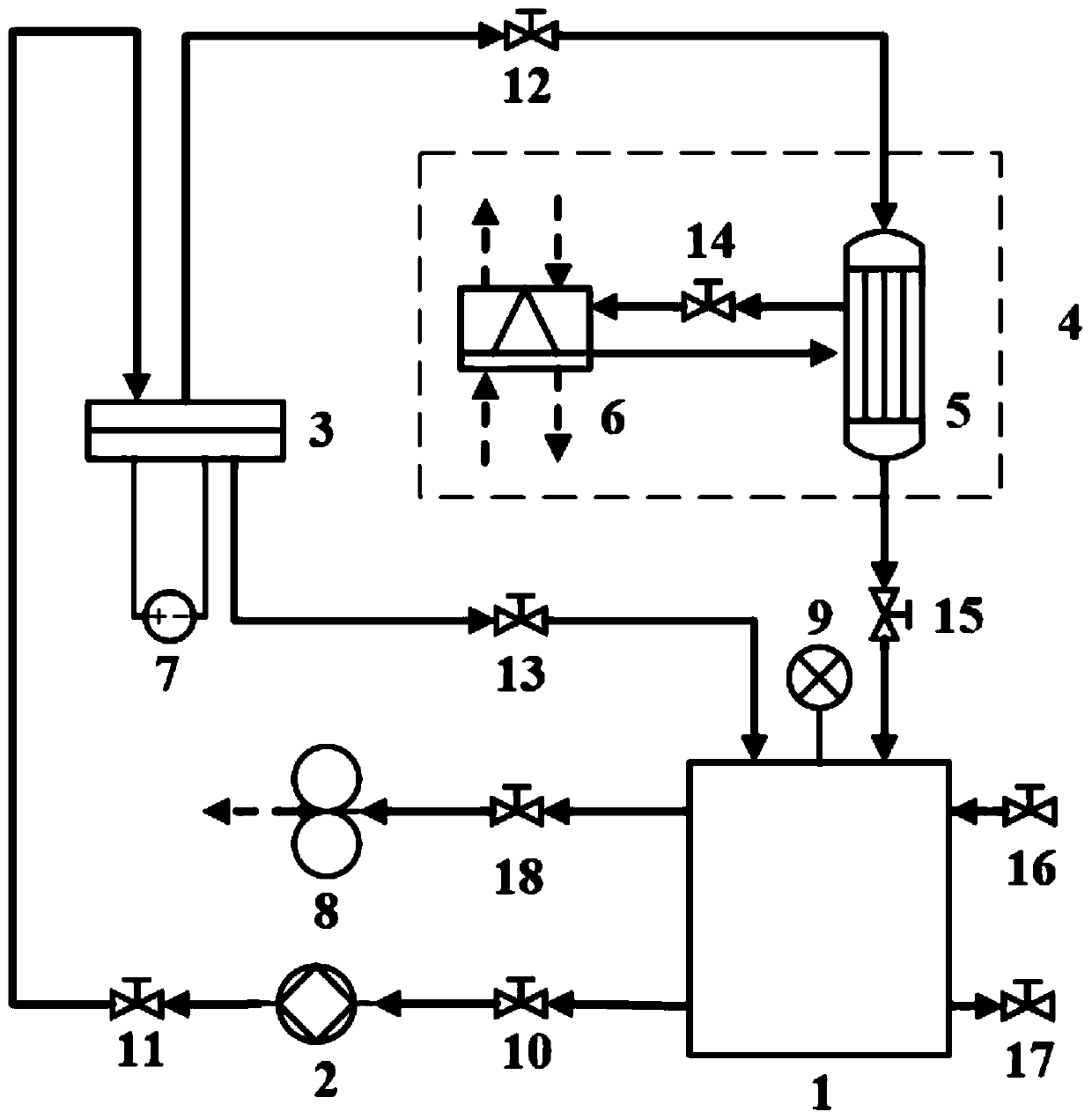

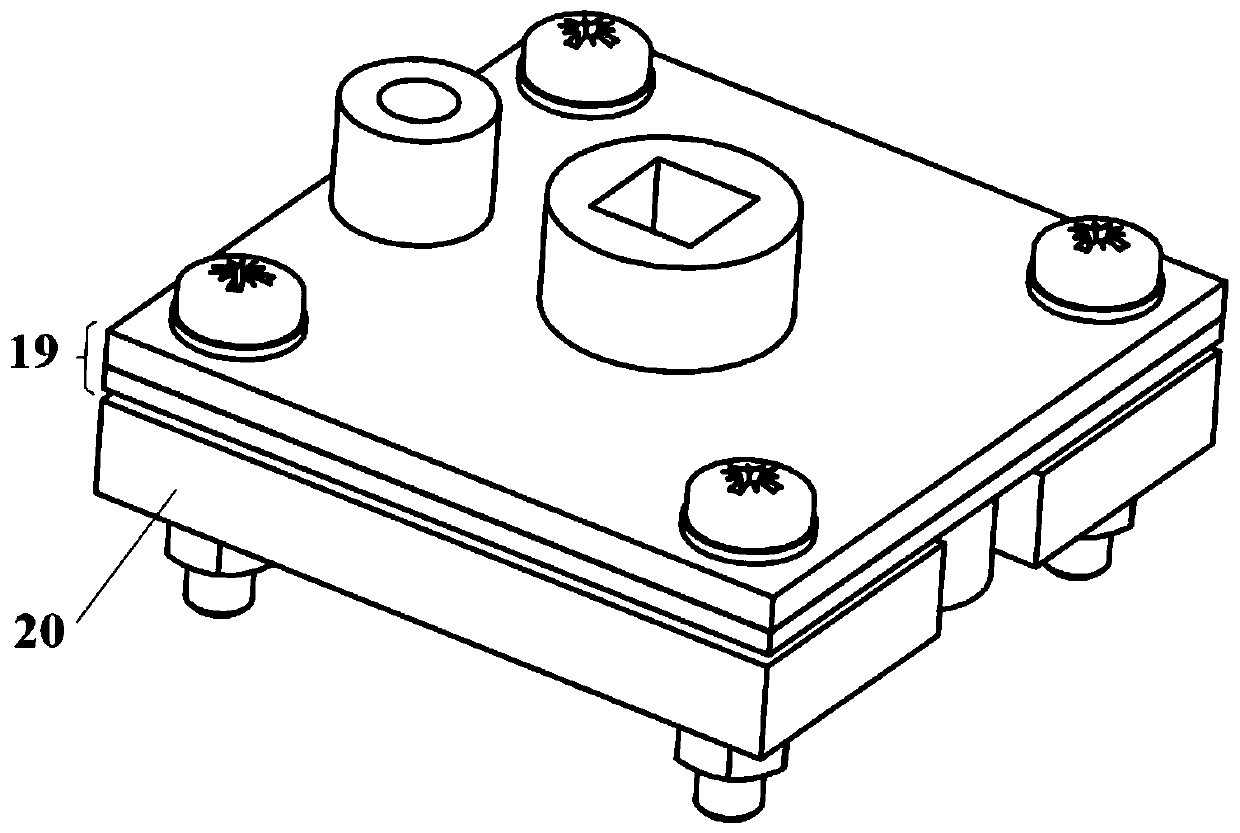

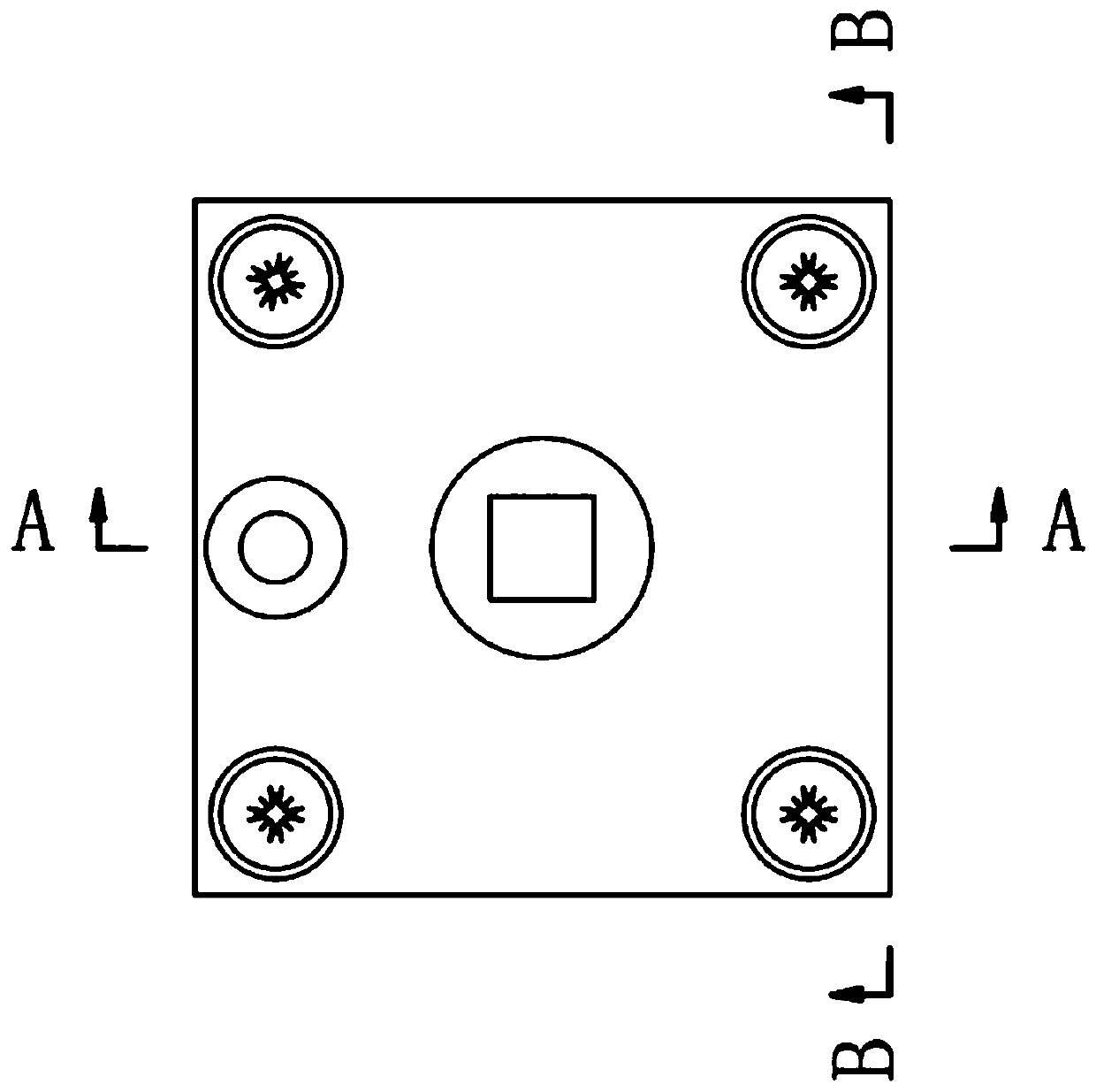

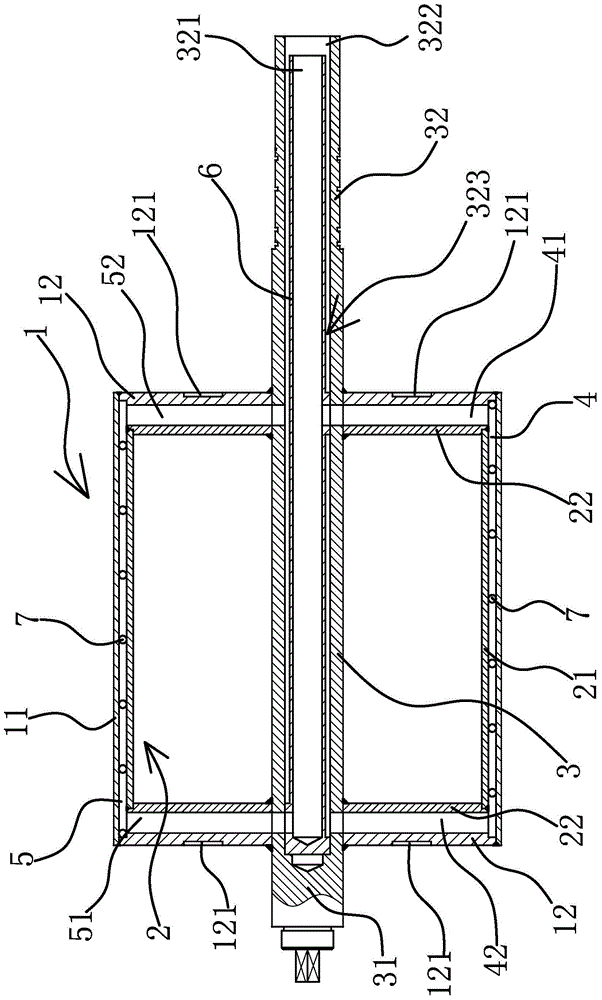

Electronic chip heat dissipation experiment device based on film evaporation

ActiveCN110650614ASpeed up evaporationReduce resistanceModifications using liquid coolingTemperature controlHeat flow

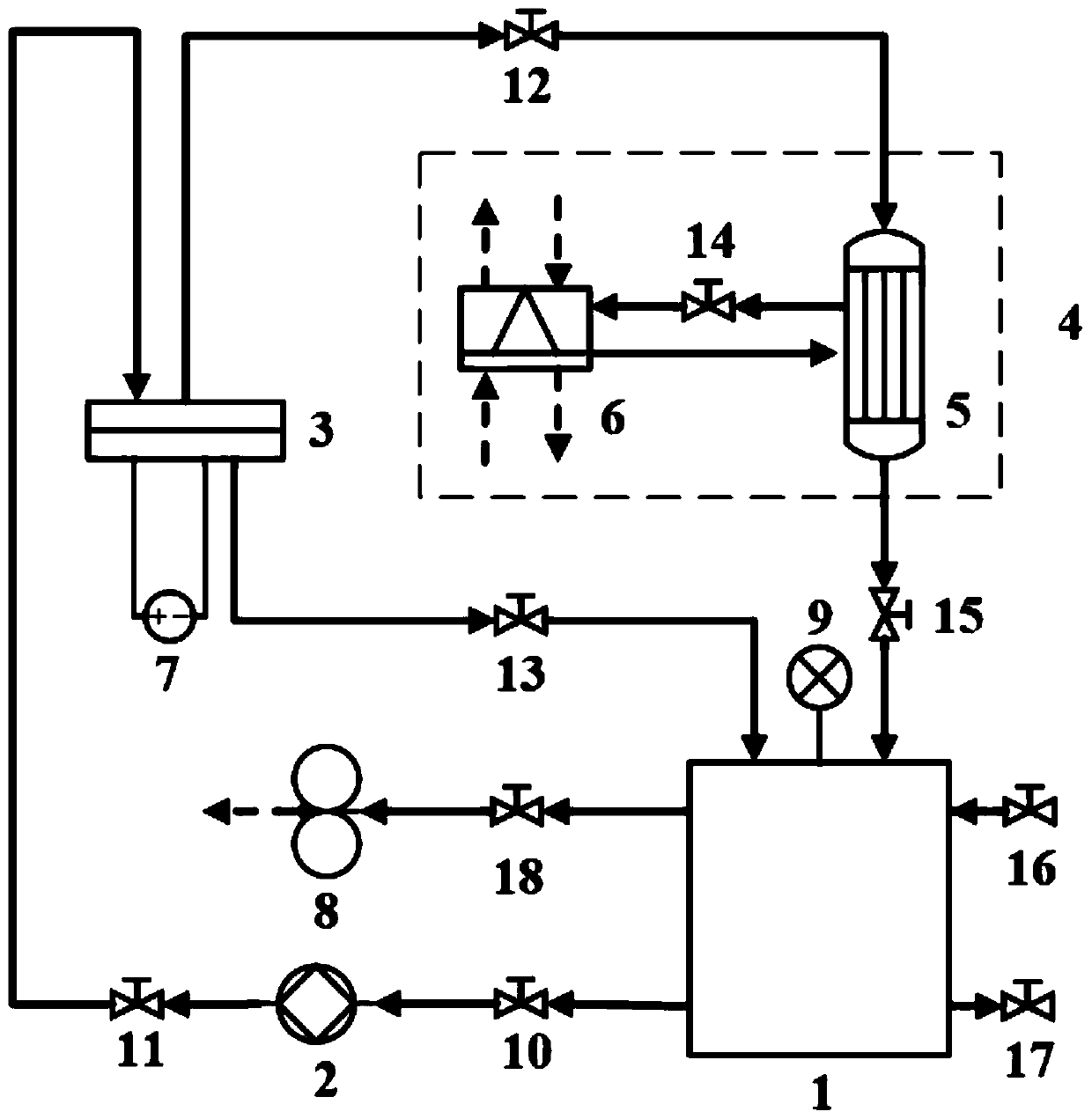

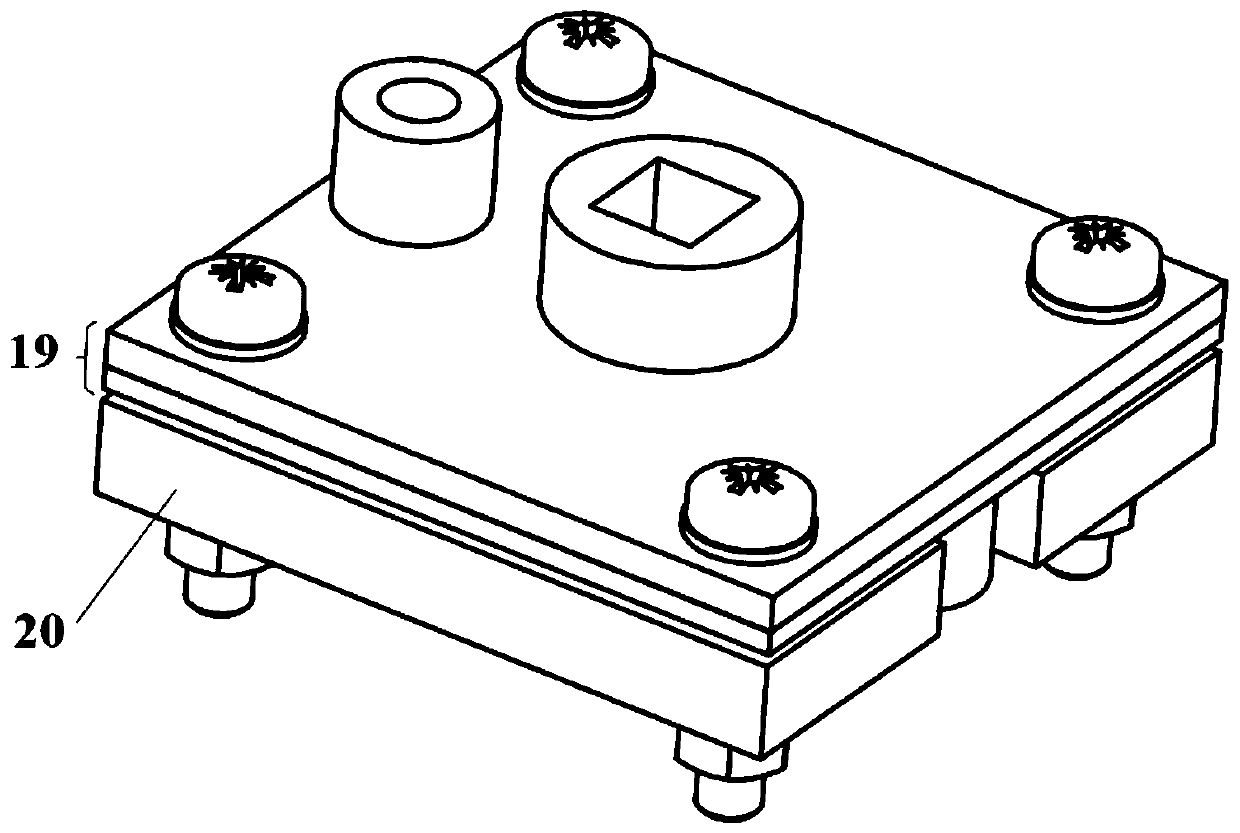

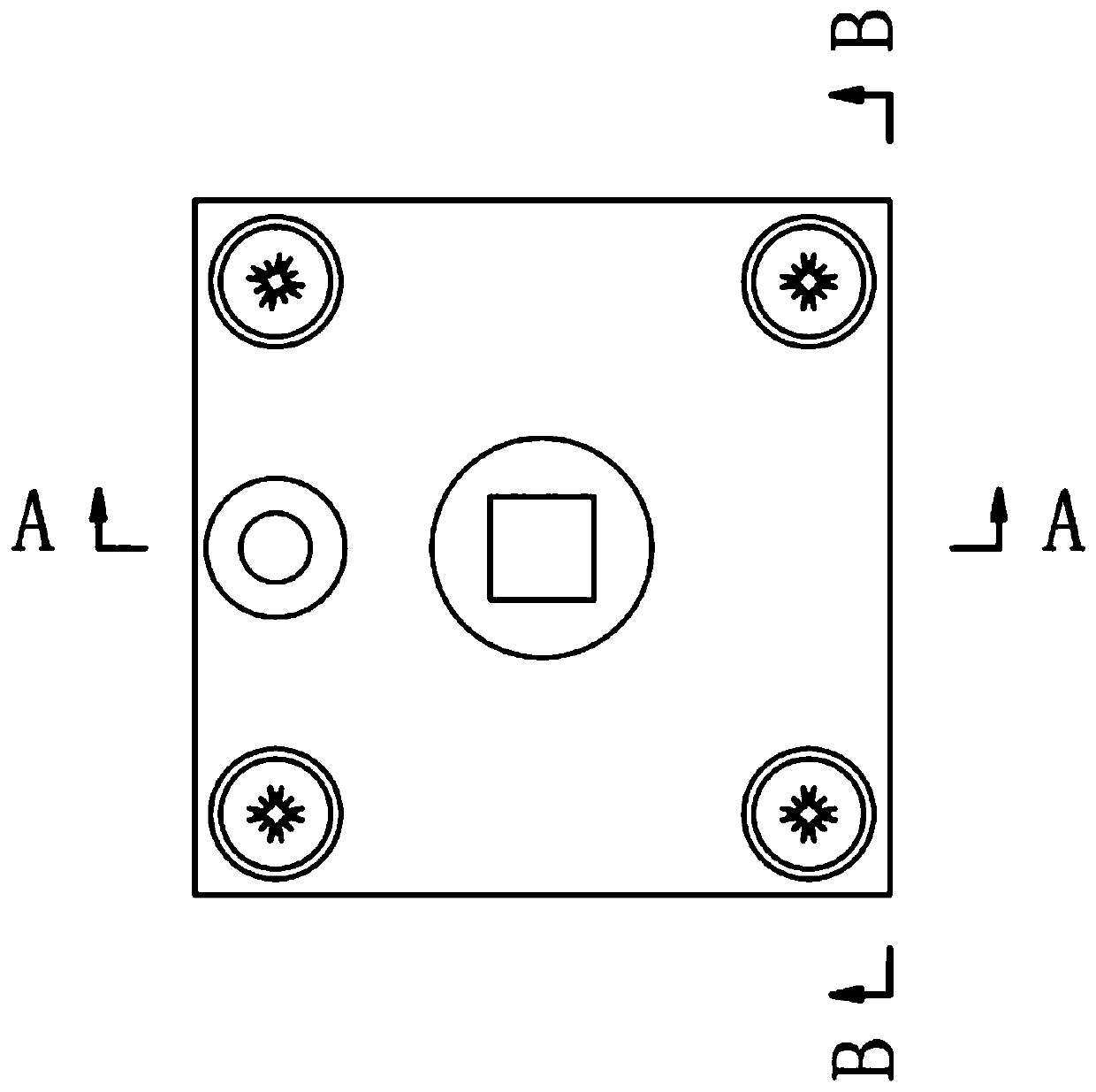

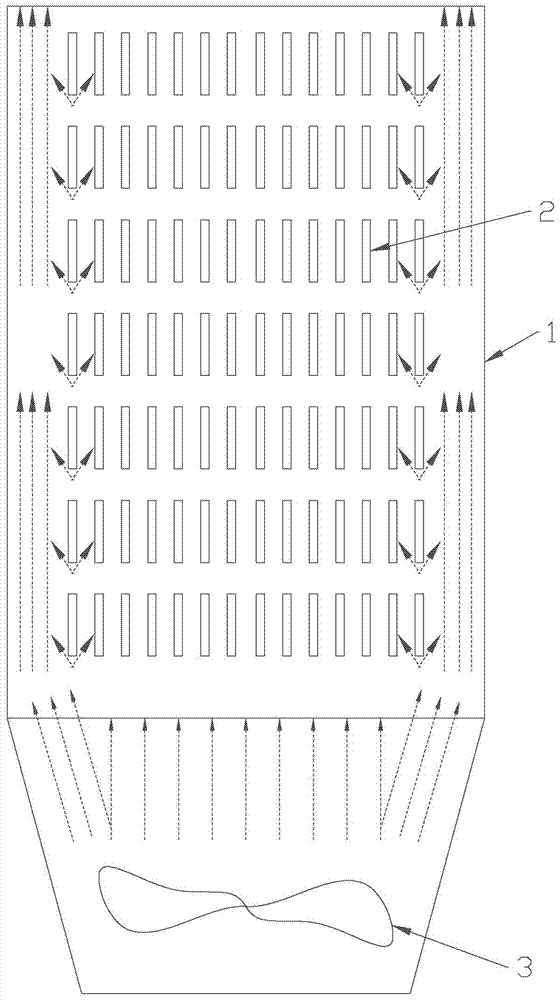

The invention discloses an electronic chip heat dissipation experiment device based on film evaporation. A cooling working medium is stored in a liquid storage tank, enters a liquid inlet of a film evaporation generator through a piezoelectric micro pump, and reaches a film evaporation chip through a liquid supply channel. The redundant cooling working medium at the film evaporation chip reaches aliquid outlet through a liquid discharge channel of the film evaporation generator, leaves the film evaporation generator and finally reaches the liquid storage tank through a pipeline. Gas directlygenerated by film evaporation at the film evaporation chip reaches a heat exchanger of a temperature control device through a gas outlet, is condensed into liquid, and finally reaches the liquid storage tank. The redundant liquid working medium and the generated gas working medium in the film evaporation generator finally return to the liquid storage tank in a liquid state to finish a cycle. The electronic chip heat dissipation experiment device has the advantages of small occupied area, low power consumption and high heat dissipation capacity, and can meet the heat dissipation requirement that the heat flow density exceeds 1kW / cm<2>.

Owner:XI AN JIAOTONG UNIV

Evaporation drum of a coating machine

InactiveCN103726021BConsistent temperatureImprove coating qualityVacuum evaporation coatingSputtering coatingInlet channelCooling effect

The invention provides an evaporation drum of a coating machine and belongs to the technical field of machinery, solving the problem of poor cooling effect of the existing evaporation drum of the coating machine. The evaporation drum of the coating machine comprises an outer cylinder, an inner cylinder and a middle shaft, wherein a first cooling flow channel and a second cooling flow channel are distributed in double helix form in the axial direction of the outer cylinder; the middle shaft penetrates through the outer cylinder and the inner cylinder; the middle shaft is provided with a liquid inlet and a liquid outlet; a first liquid inlet channel and a first liquid outlet channel are formed at the two ends of the first cooling flow channel, respectively; a second liquid inlet channel and a second liquid outlet channel are formed at the two ends of the second cooling flow channel, respectively; the port of the first liquid inlet channel and the port of the second liquid outlet channel are located on the same cross section of the middle shaft; the port of the second liquid inlet channel and the port of the first liquid outlet channel are located on the same cross section of the middle shaft; the first liquid inlet channel and the second liquid inlet channel are communicated with a liquid inlet, respectively; the first liquid outlet channel and the second liquid outlet channel are communicated with a liquid outlet, respectively. The evaporation drum of the coating machine has the advantages that the cooling liquid is evener in distribution, the surface temperature of the evaporation drum is consistent and the coating quality of the plastic thin film is better.

Owner:温岭市通茂电子装备有限公司

Composite baseboard simulated-line processing and polishing device

ActiveCN111037424ATo achieve the effect of water cooling and heat dissipationTo clean up debrisGrinding drivesGrinding machinesPull forcePolishing

The invention relates to the technical field of wood board polishing, and discloses a composite baseboard simulated-line processing and polishing device which comprises a shell. A polishing rod is movably connected into the shell; a telescopic rod is movably connected to the surface of the polishing rod; a compression spring is connected to the surface of the telescopic rod in a sleeving way; a nylon rope is movably connected to one end, far away from the polishing rod, of the telescopic rod; a sliding plate is movably connected to one end, far away from the telescopic rod, of the nylon rope;and a support frame is slidably connected to the bottom part of the sliding plate. The polishing rod can push the telescopic rod on the left side to extrude the compression ring, and the compression spring on the right side can be pulled and extended by the telescopic rod, so that the pull force of the nylon rope is largened; and the pull force of the nylon rope on the left side is small, the pullforce of the nylon rope on the right side is large, a wood board is driven by the sliding plate so as to be tilted, and the polishing rod is self-tilted and can contact a curved surface part, so thatthe effects on moving a placement table according to the movement of the polishing rod and enabling the curved surface polishing part to be accurate are achieved.

Owner:江苏富爱科技发展有限公司

Wall-mounted ozone disinfection machine

PendingCN114767913ATake away muchAvoid accumulationMechanical apparatusLighting and heating apparatusAir velocityElectric machine

The invention relates to the technical field of ozone disinfection, in particular to a wall-mounted ozone disinfection machine which comprises a bottom plate, a shell, an air inlet baffle, an air outlet baffle, a shell supporting frame, a motor, a DBD reactor, a fan fixing device and a cross-flow fan. By arranging the DBD reactor, after the rotating fan rotates, on one hand, the DBD reactor can be cooled, and on the other hand, ozone generated by operation of the DBD reactor can be guided into the flow guide cover, and the ozone and air are mixed to a certain extent in the flow guide process; the airflow generated by the rotary fan can take away more ozone as much as possible under the condition of not influencing the air velocity in the DBD reactor, so that the problem that the ozone is accumulated near the DBD reactor is avoided; according to the hollow exhaust pipe, the exhaust holes are continuously distributed in the surface of the hollow cylinder at equal intervals, so that air and ozone flowing into the hollow exhaust pipe can be uniformly released into the cross-flow fan through the exhaust holes in the surface of the hollow exhaust pipe, and the problem that ozone cannot be uniformly discharged is avoided.

Owner:安徽冠东电子科技有限公司

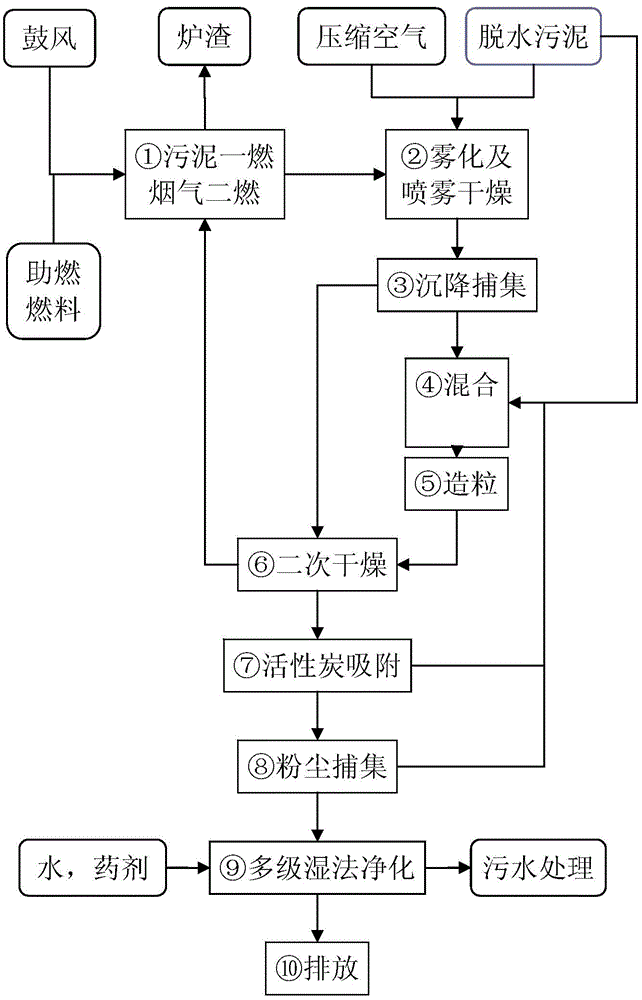

A method for drying and incinerating dewatered sludge

ActiveCN104310746BReduce consumptionEmission reductionCombination devicesSludge treatment by de-watering/drying/thickeningActivated carbonSlag

The invention provides a method for drying and incinerating treatment of dewatered sludge. The method comprises the following steps: inputting high-temperature smoke generated by incinerating dry sludge as a heat source into a spraying drying tower; atomizing the dewatered sludge, mixing the atomized sludge with the high-temperature smoke in a flow combination way in the spraying drying tower, drying to half dryness, and in the meantime, rapidly reducing the temperature of the smoke and adsorbing fly ash; collecting the half-dried sludge after spraying drying, and performing mechanical extruding granulation; further drying the half-dried sludge particles with the afterheat of the smoke after the spraying drying; conveying the dried sludge particles into an incinerator for 3T incineration and discharging residual slags; and performing activated carbon adsorption on the dried tail gas, then feeding the tail gas to a deduster and a multi-stage wet-process spraying tower for purification treatment and discharging the tail gas. The method provided by the invention has the beneficial effects of being capable of realizing the drying and incinerating treatment of the sludge in a complete, efficient, environment-friendly and safe way. The process steps are simplified and the process route is shortened.

Owner:星河航天科技(天津)有限公司

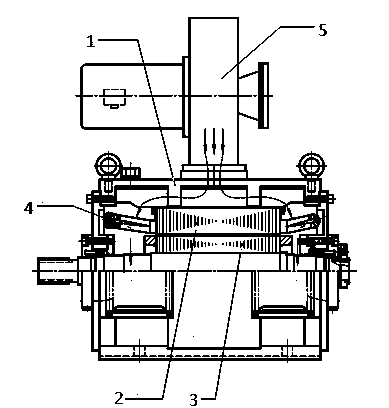

An electric turbocharger

ActiveCN108644005BReduce in quantityReduce modelInternal combustion piston enginesEngine componentsElectric machineTurbocharger

Owner:滨州高新高端装备制造产业园有限公司

A turbine blade with transverse meandering and alternately shortening and shortening channels inside

ActiveCN110863864BIncrease heat absorptionReduce the temperatureBlade accessoriesMachines/enginesCold airSuction force

Owner:SHENYANG AEROSPACE UNIVERSITY

Mold for quick injection molding of fan blades

InactiveCN103407136ARapid cooling and settingAccelerate cooling and setting speedWater flowCooling effect

The invention discloses a mold for quick injection molding of fan blades. The mold comprises a mold body and an upper mold matched with the mold body, wherein fan blade injection molding grooves are formed in the mold body; cold water flowing pipelines are arranged in the mold body, and positioned at the bottoms of the fan blade injection molding grooves; a pull ring is fixed on the side surface of the mold body. The mold has the advantages that a cooling effect is good, the cooling and forming speed of the fan blades can be increased, and the production efficiency of the fan blades can be improved.

Owner:成都万顺达模具零件有限公司

Low-voltage side filtering compensation energy-saving rectifier transformer

InactiveCN113345691AAvoid the influence of cooling effectAvoid affecting cooling efficiencyTransformers/inductances coolingCleaning using toolsTransformerEngineering

The invention discloses a low-voltage side filtering compensation energy-saving rectifier transformer. The transformer comprises a transformer shell, a connecting sleeve is fixedly arranged at the top of the transformer shell, an oil level gauge is connected to one end of the top of the transformer shell, a fixing seat is fixedly arranged at the bottom of the transformer shell, one side of the transformer shell is connected with an integrated heat dissipation main body, and a sliding groove is formed in the inner side of the heat dissipation main body; if dust falls into the heat dissipation main body, a scraping plate can be moved up and down in the overhaul and maintenance process; the interior of the heat dissipation main body is cleaned through the scraping plate, dust is prevented from being attached to the inner surface of the heat dissipation main body, the heat dissipation effect is not affected, and the convenience of the device is improved;heat dissipation through holes are formed in the surface of the heat dissipation main body, air flow on the surface of the heat dissipation body can be accelerated through the heat dissipation through holes, more heat is taken away, the heat dissipation efficiency is improved, and the practicability of the device is improved.

Owner:HUNAN HONGYE TRANSFORMER

A resistance box that facilitates air conduction and heat dissipation

ActiveCN107039132BReduce churnTake away muchResistor housing/enclosing/embeddingThermal insulationEngineering

Owner:GUANGDONG FULLDE ELECTRONICS +1

A processing and grinding device for simulated pattern of synthetic bottom plate

ActiveCN111037424BTo achieve the effect of water cooling and heat dissipationTo clean up debrisGrinding drivesGrinding machinesEngineeringSlide plate

The invention relates to the technical field of wood board grinding, and discloses a device for processing and grinding synthetic base boards with simulated textures, including a housing. A grinding rod is movably connected to the inside of the housing. The surface of the grinding rod is movably connected to a telescopic rod. The surface is sleeved with a compression spring, and the end of the telescopic rod away from the polishing rod is movably connected with a nylon rope, and the end of the nylon rope far away from the telescopic rod is movably connected with a sliding plate, and the bottom of the sliding plate is slidably connected with a support frame. The grinding rod will push the telescopic rod on the left to squeeze the compression spring, and the compression spring on the right will be stretched by the telescopic rod, that is, the pulling force of the nylon rope becomes larger, the tension of the nylon rope on the left is small, and the tension of the nylon rope on the right is large In addition, because the wooden board is tilted by the sliding plate and the grinding rod itself is inclined, the grinding rod will be in contact with the curved surface, so that the placing table can move according to the movement of the grinding rod, and the grinding position of the curved surface is accurate.

Owner:江苏富爱科技发展有限公司

An experimental device for heat dissipation of electronic chips based on thin film evaporation

ActiveCN110650614BSpeed up evaporationReduce resistanceModifications using liquid coolingLiquid storage tankEngineering

The invention discloses an electronic chip heat dissipation experiment device based on film evaporation. A cooling working medium is stored in a liquid storage tank, enters a liquid inlet of a film evaporation generator through a piezoelectric micro pump, and reaches a film evaporation chip through a liquid supply channel. The redundant cooling working medium at the film evaporation chip reaches aliquid outlet through a liquid discharge channel of the film evaporation generator, leaves the film evaporation generator and finally reaches the liquid storage tank through a pipeline. Gas directlygenerated by film evaporation at the film evaporation chip reaches a heat exchanger of a temperature control device through a gas outlet, is condensed into liquid, and finally reaches the liquid storage tank. The redundant liquid working medium and the generated gas working medium in the film evaporation generator finally return to the liquid storage tank in a liquid state to finish a cycle. The electronic chip heat dissipation experiment device has the advantages of small occupied area, low power consumption and high heat dissipation capacity, and can meet the heat dissipation requirement that the heat flow density exceeds 1kW / cm<2>.

Owner:XI AN JIAOTONG UNIV

Resistance box with convenience in air guiding and heat dissipating

ActiveCN107039132AReduce churnTake away muchResistor housing/enclosing/embeddingThermal insulationEngineering

The invention discloses a resistance box with convenience in air guiding and heat dissipating. The resistance box comprises a hollow box body with an inner cavity; the box body comprises continuous bearing section and accommodating section; the accommodating section is used for placing resistance elements; a fan which blows air towards the accommodating section is arranged in the bearing section; air guiding parts are fixed on the inner wall of the accommodating section; and the air guiding parts are inclined towards the inner cavity of the box body. By virtue of the air guiding parts in the box body, (1) air flow loss is lowered, air flow which flows through the resistance elements is higher in amount, and more heat can be taken away under the effect of the fan of the same powder, so that partial overhigh temperature of the box body can be avoided and the heat dissipation effect is improved; (2) turbulent current is formed between the resistance elements, so that heat generated by the resistance elements can be taken away more easily; and (3) the air guiding parts are directly impacted by the air flow, and the heat on the side wall of the box body can be taken away by the air guiding parts, so that the air guiding parts also can have a thermal insulation effect, thereby lowering the temperature of the side wall of the box body, and reducing heat dissipation from the side surface of the box body.

Owner:GUANGDONG FULLDE ELECTRONICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com