Induction heating furnace with induction coil clearance type heat dissipation

A technology of induction heating furnace and induction coil, which is applied in the direction of induction heating, electric furnace heating, coil device, etc., which can solve the problems that the induction coil generates too much heat and natural heat dissipation cannot meet the requirements of use, and achieve the effect of long-term work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

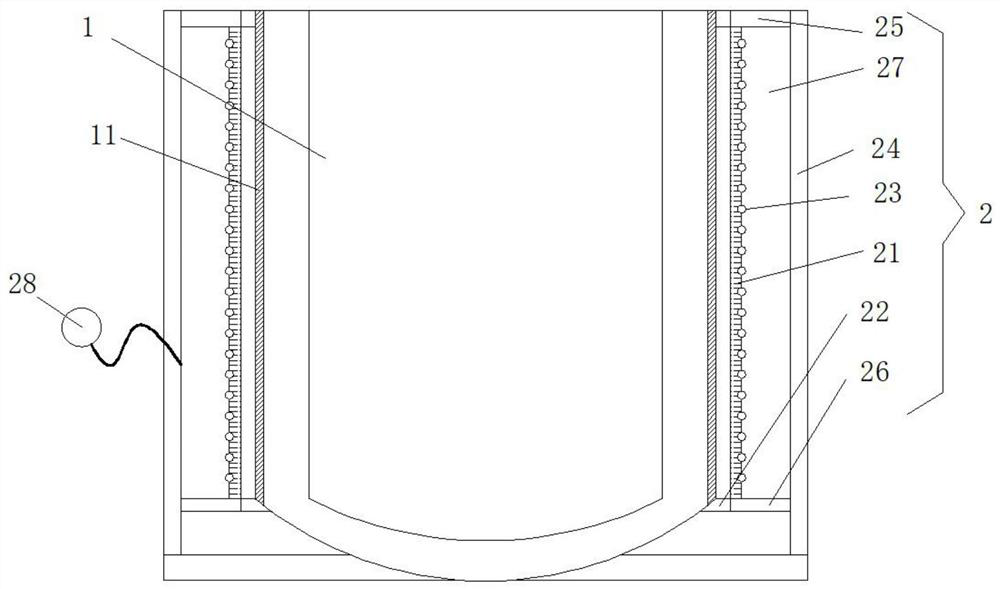

[0020] like figure 1 As shown, the induction heating furnace for the induction coil gap heat dissipation described in this embodiment includes a furnace 1, and the outside of the furnace 1 is provided with a coil installation mechanism 2, and the coil installation mechanism 2 includes an inner cylinder 21. The inner cylinder 21 is coaxially sleeved on the furnace 1, and the inner wall of the inner cylinder 21 is fixedly connected with several connecting blocks 22, and the connecting blocks 22 are also fixedly connected to the outer wall of the furnace 1, and the two ends of the inner cylinder 21 are Open, and there are a plurality of through holes evenly on the wall of the inner cylinder 21, the outer wall of the inner cylinder 21 is wound with an induction coil 23, and the adjacent coils on the induction coil 23 do not contact each other. The outer coaxial sleeve of the inner cylinder 21 is provided with an outer cylinder 24, and the top and bottom ends between the outer cyli...

Embodiment 2

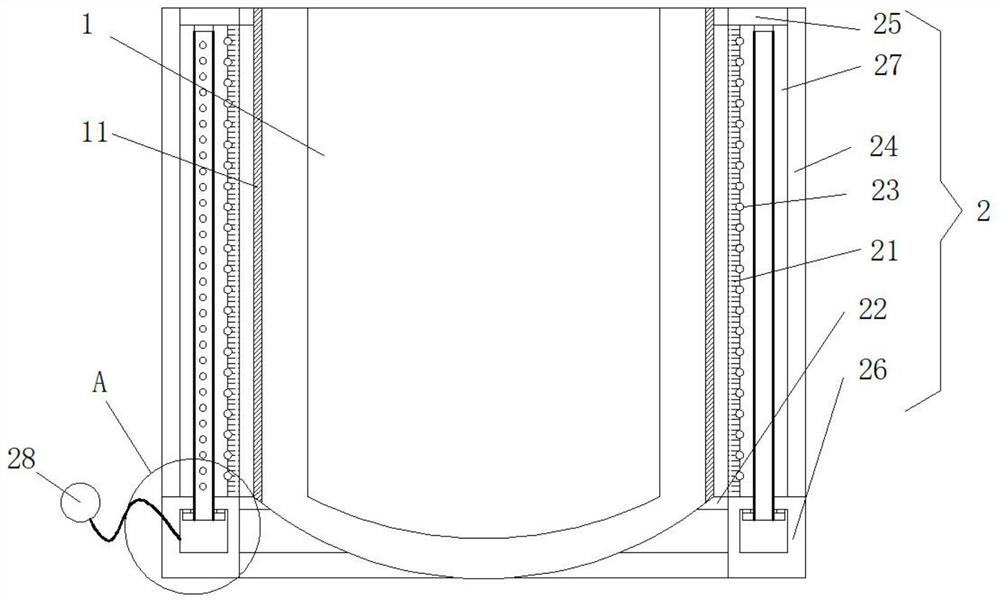

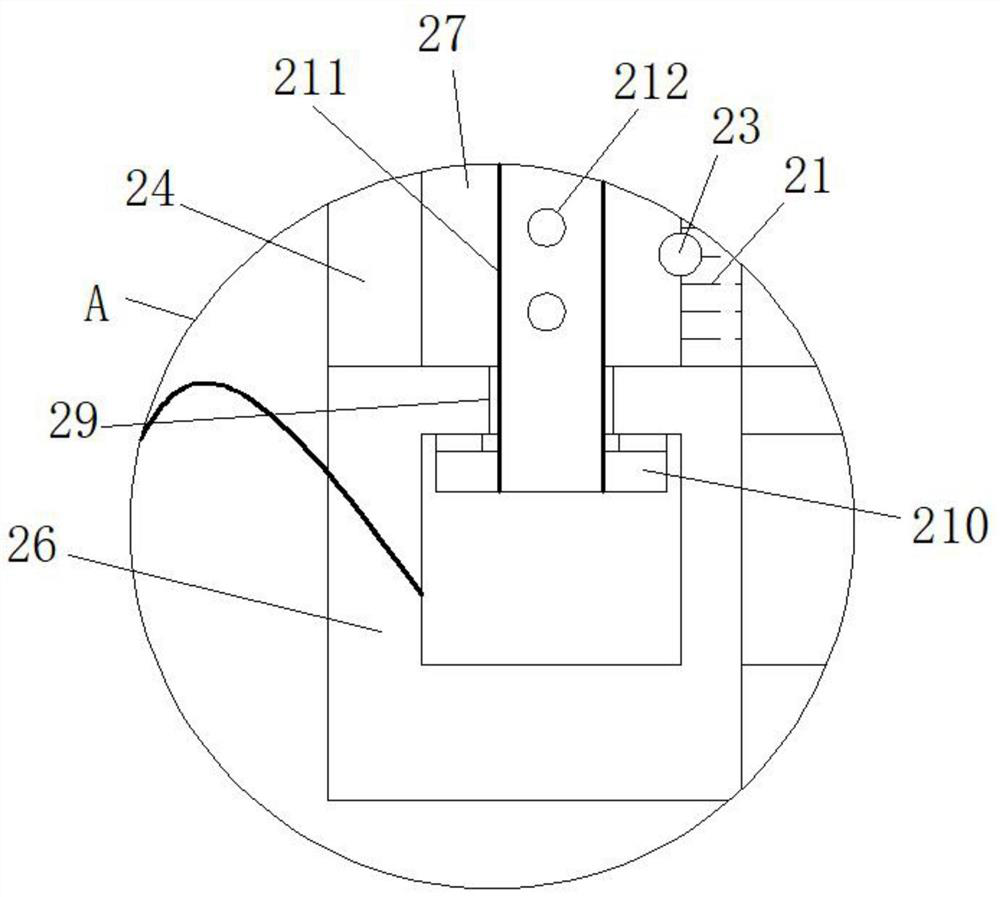

[0026] like Figure 2-3 As shown, the induction heating furnace for the induction coil gap heat dissipation described in this embodiment includes a furnace 1, and the outside of the furnace 1 is provided with a coil installation mechanism 2, and the coil installation mechanism 2 includes an inner cylinder 21. The inner cylinder 21 is coaxially sleeved on the furnace 1, and the inner wall of the inner cylinder 21 is fixedly connected with several connecting blocks 22, and the connecting blocks 22 are also fixedly connected to the outer wall of the furnace 1, and the two ends of the inner cylinder 21 are Open, and there are a plurality of through holes evenly on the wall of the inner cylinder 21, the outer wall of the inner cylinder 21 is wound with an induction coil 23, and the adjacent coils on the induction coil 23 do not contact each other. The outer coaxial sleeve of the inner cylinder 21 is provided with an outer cylinder 24, and the top and bottom ends between the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com