A Thermal Data Acquisition Smart Current Regulation Battery Box with Replaceable Battery Units

A current regulation, battery cell technology, applied in electrical components, secondary batteries, battery pack components, etc., can solve the problems of inability to achieve heat exchange, shortened battery life, and inability to accurately judge technology, and achieve broad application prospects and Market prospects, meet the needs of long-term work, and achieve the effect of independent intelligent air cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the stated scope.

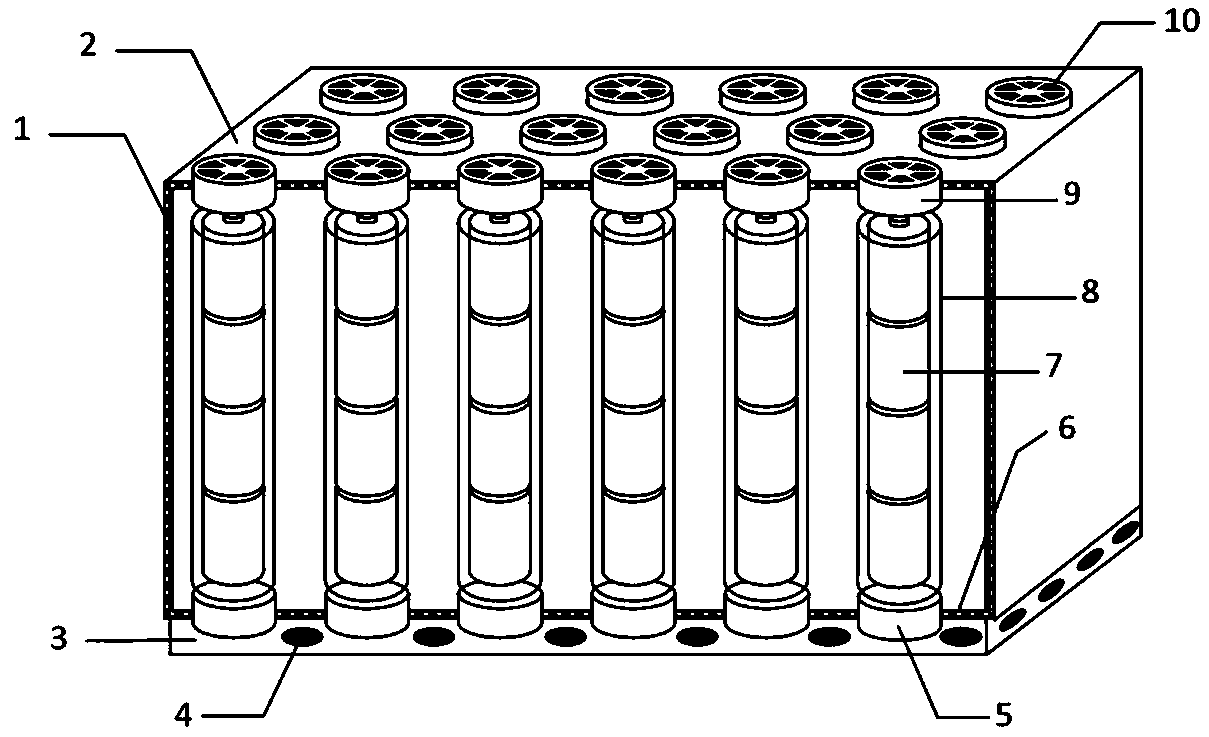

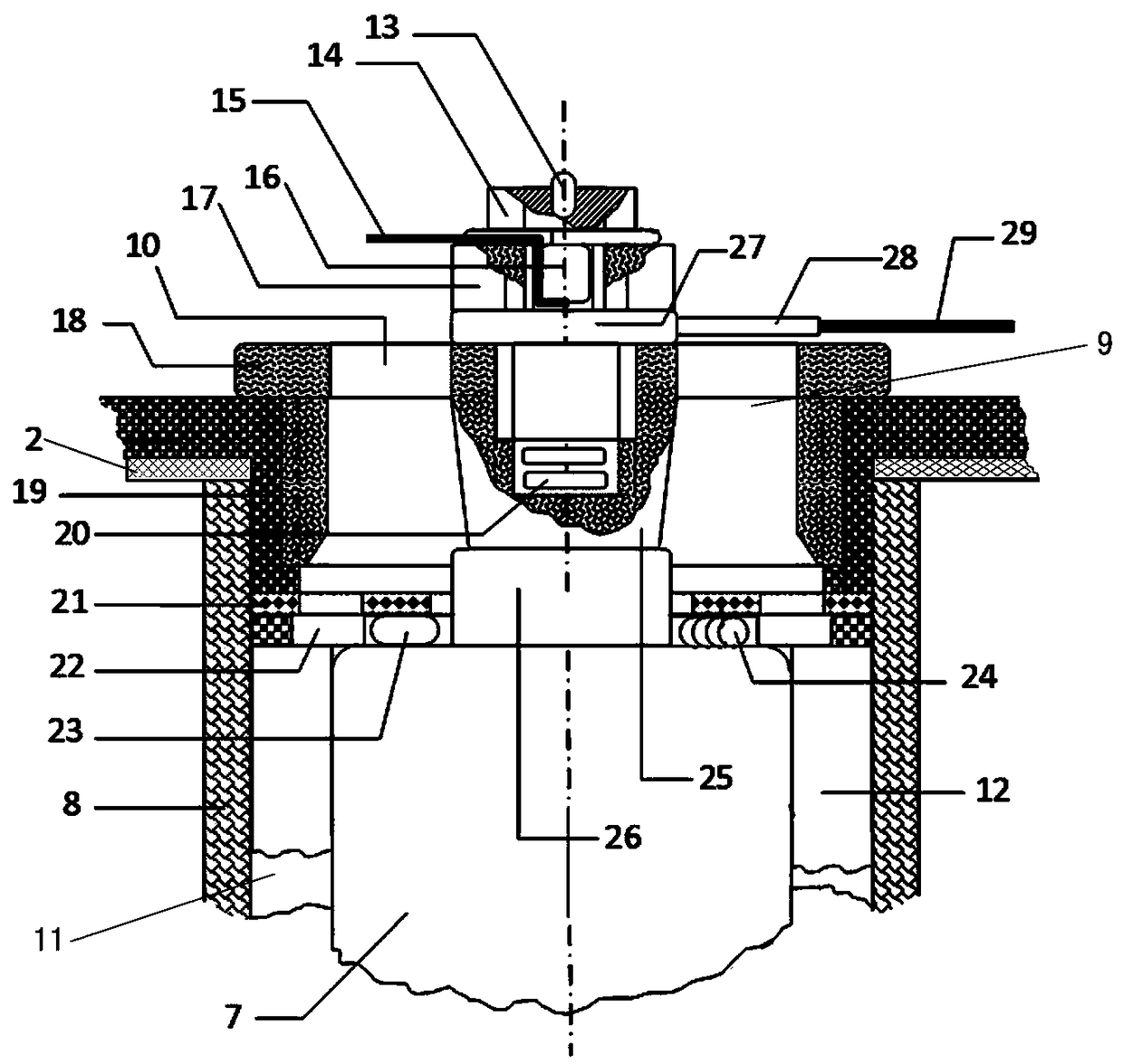

[0045] The specifications and structures of the top plate 2 and the bottom plate 6 of the battery box body 1 of the present invention are exactly the same, and are all provided with dense sleeve fixing round platforms 19, and the distance between all the sleeve fixing round platforms 19 and the mounting holes on the top plate 2 and the bottom plate 6 is less than 2 The area of the top plate 2 and the bottom plate 6 is determined according to the number of battery packs. The top plate, the bottom plate and the side plates of the battery box are connected and fixed by screws to form the battery box body, and the assembled sleeves of the top plate 2 and the bottom plate 6 are fixed. The positions of the round tables 19 correspond precisely, and the casing 8 of the battery pack is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com