A high frequency intermittent valve device based on valve core rotation

A valve core rotating, intermittent valve technology, applied in the valve operation/release device, valve device, cock including cut-off device, etc. The effect of a wide range, wide range, high intermittent operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

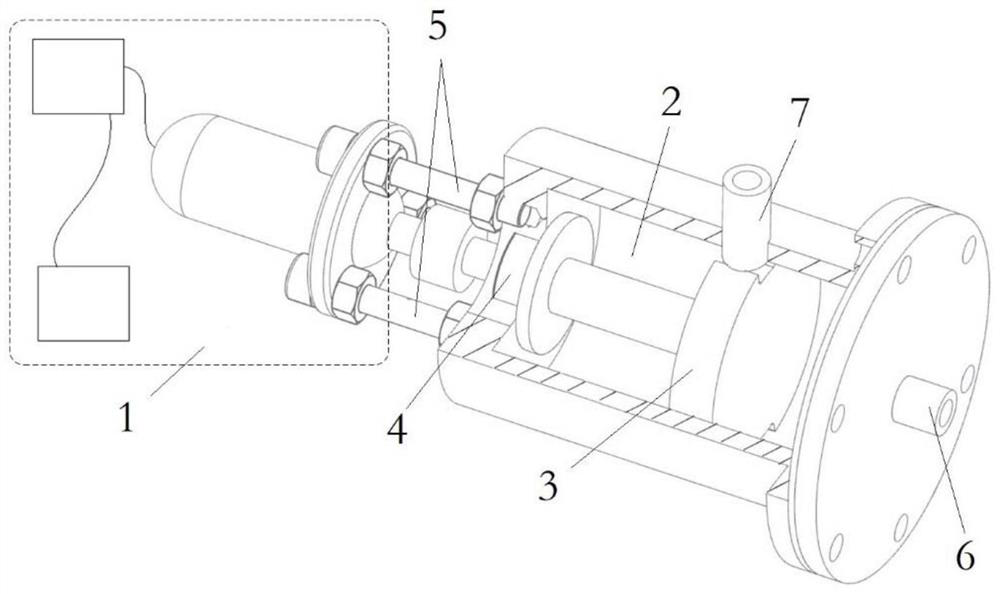

[0059] like Figure 1-7 As shown, a high-frequency intermittent valve device based on valve core rotation provided in this embodiment includes:

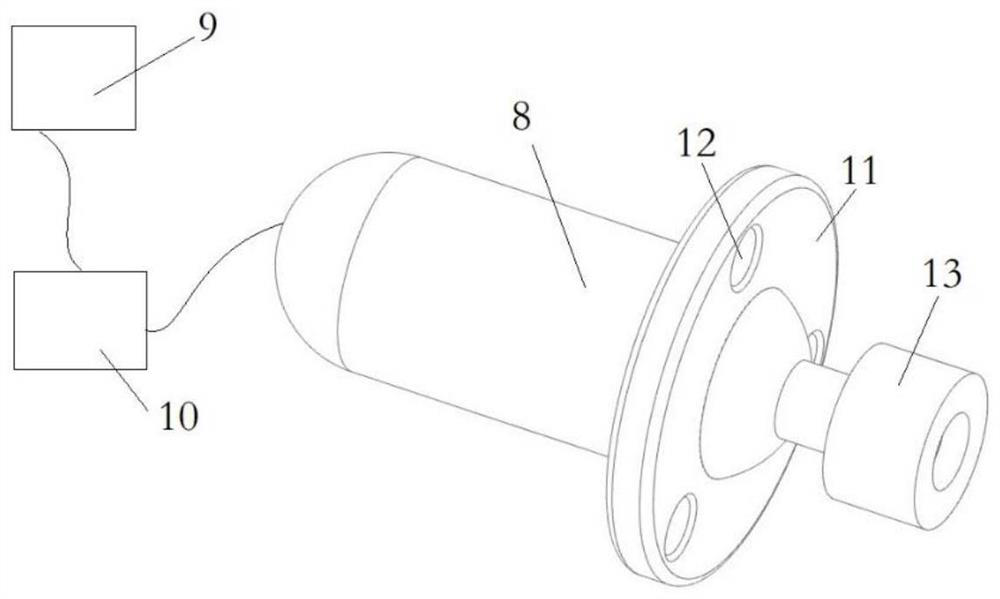

[0060] Drive assembly 1, the drive assembly 1 is composed of a servo motor 8, a controller 9 and a driver 10, and the speed of the servo motor 8 is controlled by the controller 9 during use, thereby further controlling the speed of the rotary valve core 3;

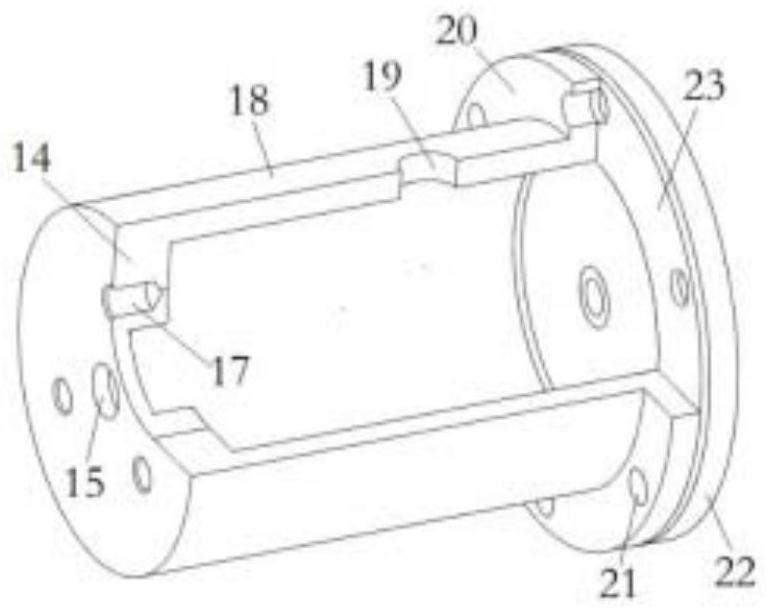

[0061] Fluid chamber 2, the fluid chamber 2 is a cylindrical component;

[0062] The rotary valve core 3 is installed inside the fluid chamber 2, and the end of the rotary valve core 3 is connected to the drive assembly 1. In this embodiment of the present application, the drive assembly drives the rotary valve core 3 to move in the fluid. Cavity 2 rotates inside;

[0063] a fluid outlet 7, the fluid outlet 7 is arranged on the side of the fluid chamber 2;

[0064] A fluid inlet 6 is provided at the end of the fluid chamber 2 .

[0065] Specifically, the drive assembly 1 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com