Air filter assembly applied to automobiles

An air filter and assembly technology, applied in the field of auto parts, can solve problems such as undiscovered product related reports, and achieve the effects of improving fuel economy, small air intake resistance, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

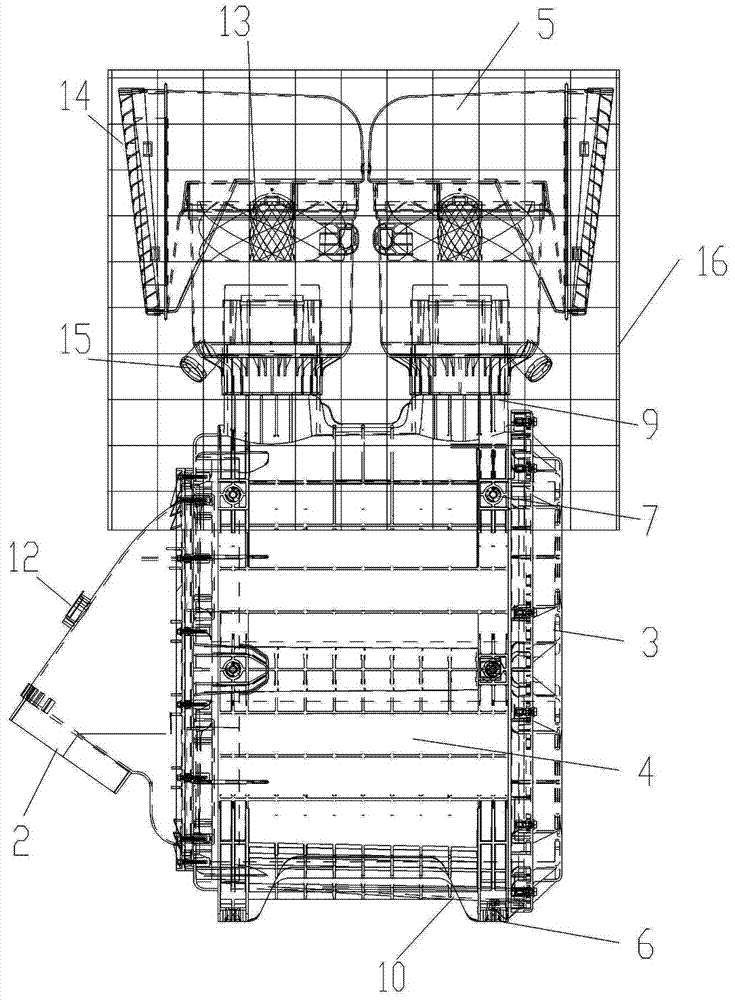

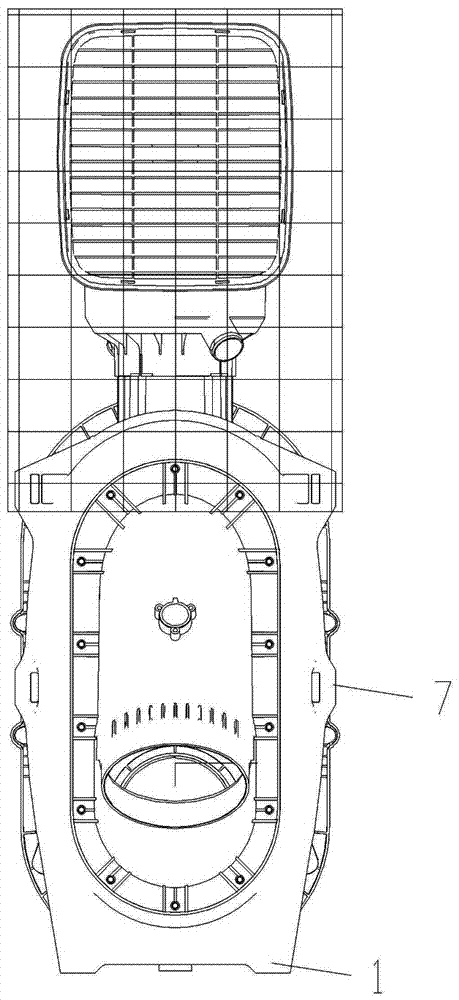

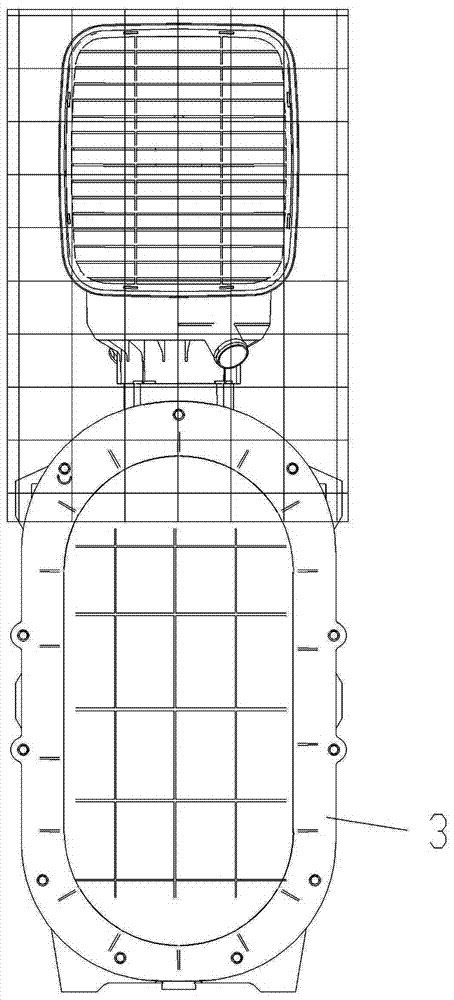

[0032] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

[0033] Such as Figure 1 to Figure 5 As shown, an air filter assembly for automobiles includes: a body shell 1 , an air outlet shell 2 , an end cover 3 , a filter element 4 , two pre-filters 5 , and an anti-sand net 16 .

[0034] Wherein, the bottom of the body shell 1 is provided with 4 mounting threaded seats 6 for fixing, 4 auxiliary mounting threaded seats 7 are provided on the top of both sides, and 2 circular holes for installing the pre-filter 5 are provided on the top. The air inlet 9 is provided with handles 8 for easy handling on both sides of the upper part; the inner bottom of the body shell 1 is provided with a downwardly inclined water collection tank 10 and a downwardly facing dust outlet connected to the water collection tank 10 away from the air outlet 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com