Dual ultrasonic heat pipe cooling device

A cooling device, ultrasonic technology, applied in the direction of heat transfer modification, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of carrying limit drying limit, limited moving speed, hindering shear force, etc., to increase the carrying limit and drying limit, accelerated heat exchange rate, and accelerated liquid reflux effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

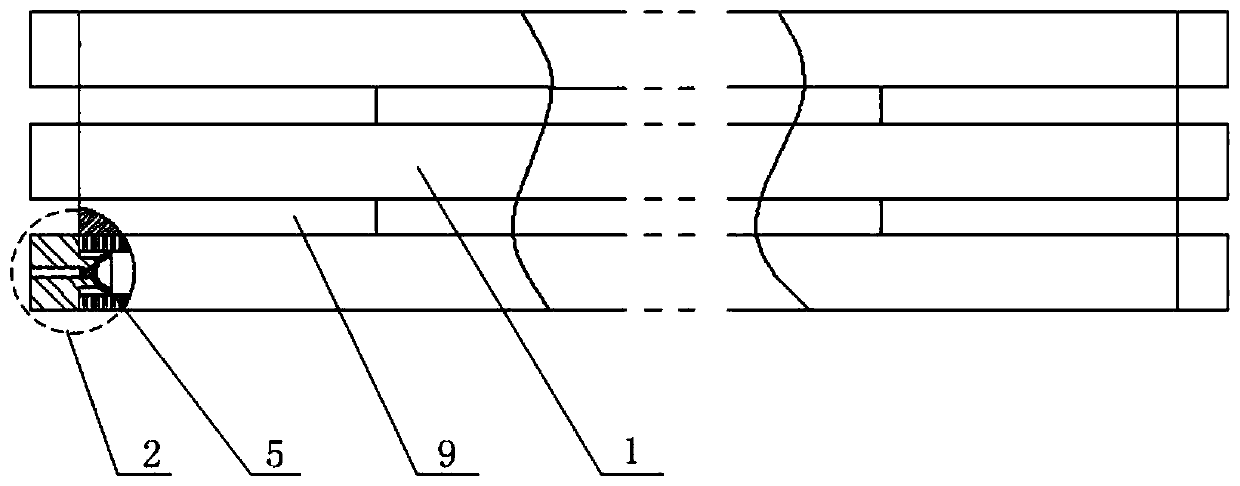

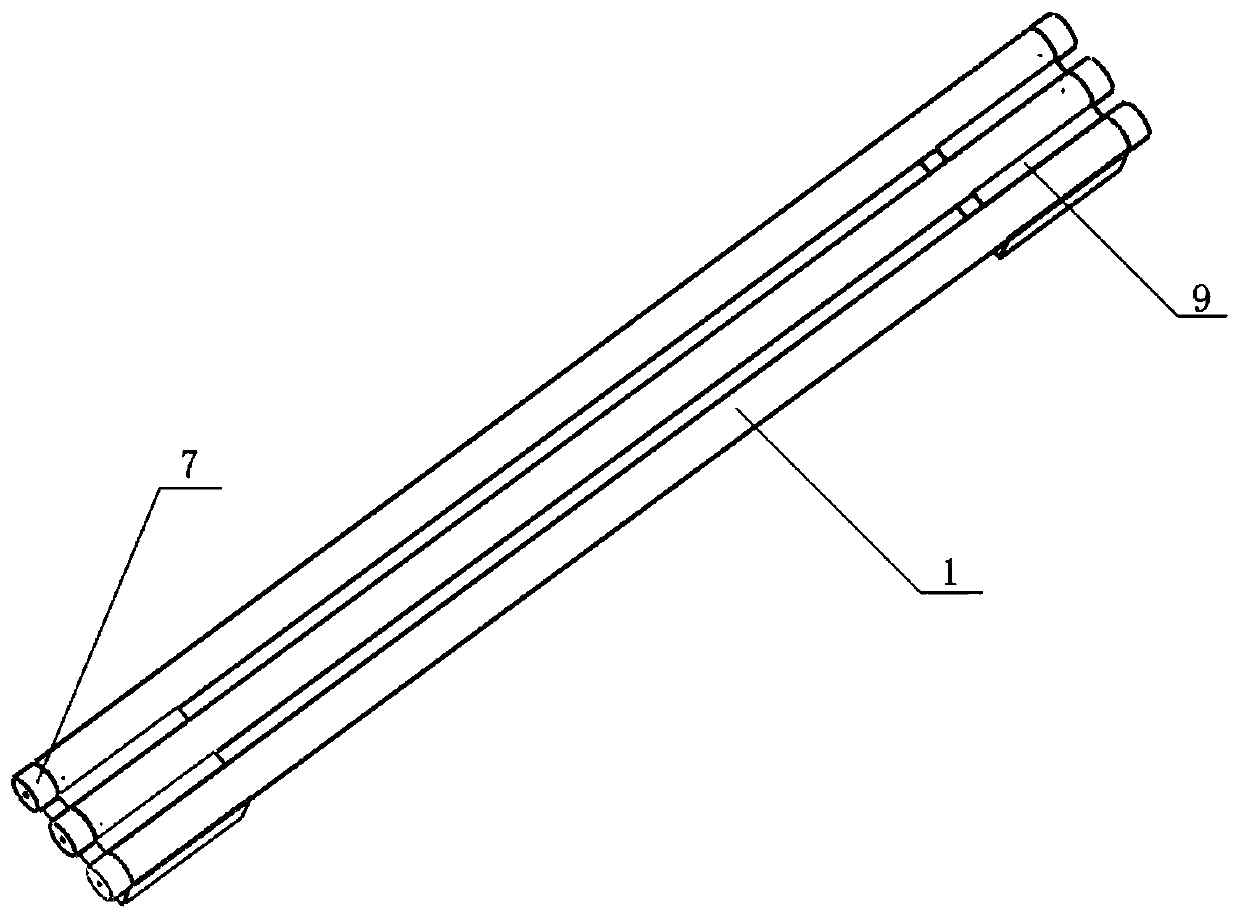

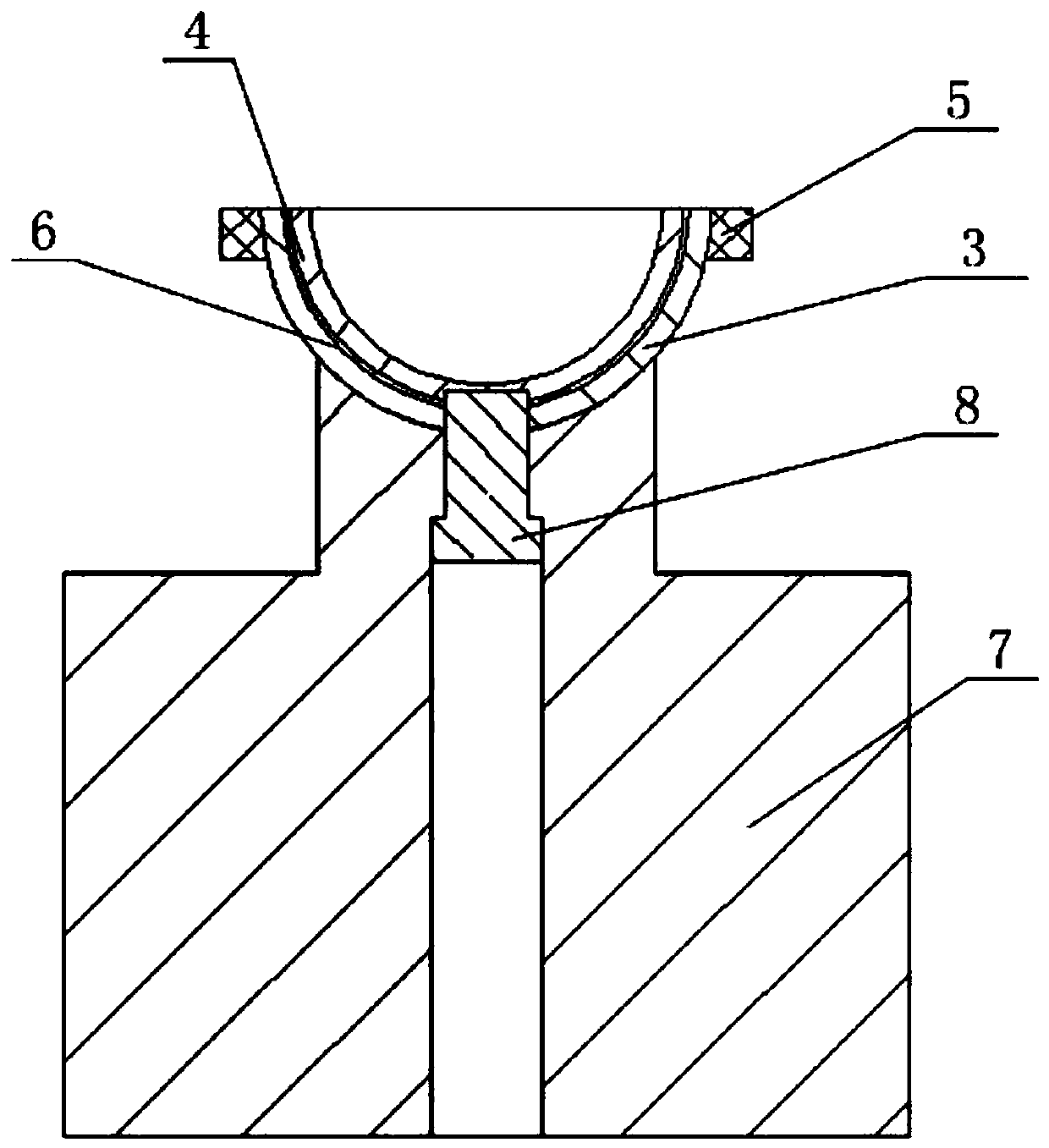

[0024] The invention provides a double ultrasonic heat pipe cooling device, such as Figure 1-4 As shown, it includes a heat pipe 1, the heat pipe 1 contains a liquid-absorbing core, the heat pipe 1 includes a hot end and a condensation end, and the heat pipe 1 is provided with a piezoelectric ultrasonic transducer 2 at the hot end and the condensation end respectively. The transducer 2 generates ultrasonic waves of different frequencies at the hot end and the condensing end, the frequency range of the ultrasonic wave at the hot end is 20kHz-40kHz, and the frequency range of the ultrasonic wave at the condensing end is 400kHz-700kHz; the piezoelectric ultrasonic transducer 2 includes piezoelectric ceramics 3 And the vibrator 4 connected with the piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com