Drying tunnel used for heating and dehumidifying water paint

A technology of heating and dehumidification, water-based paint, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of social environment impact, air and water discharge pollution, etc., and achieve the effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

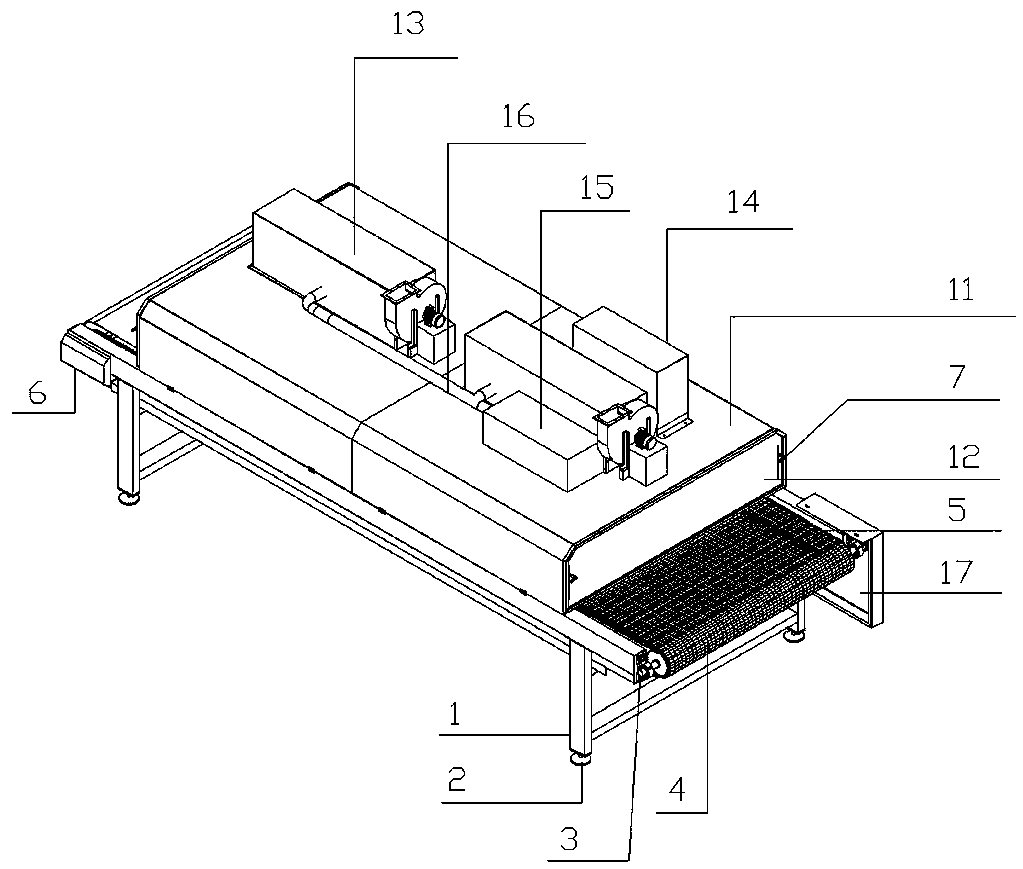

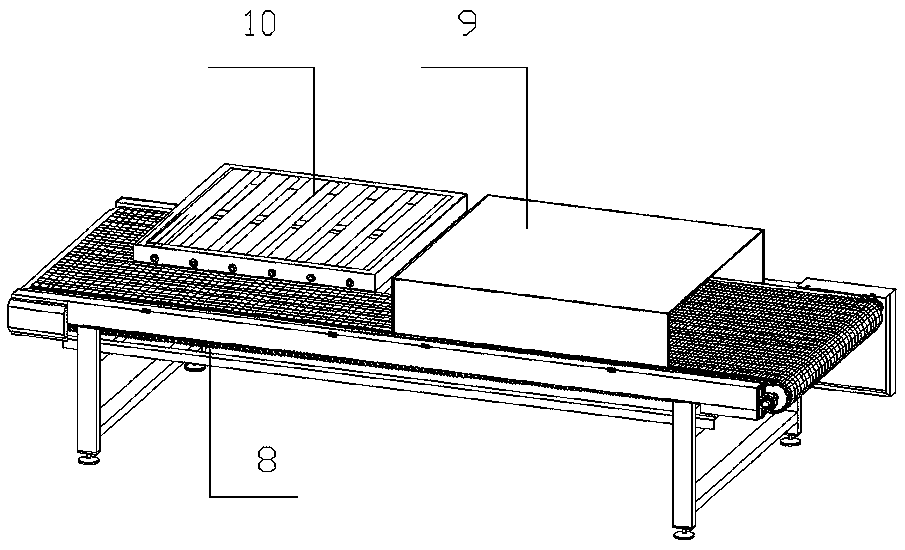

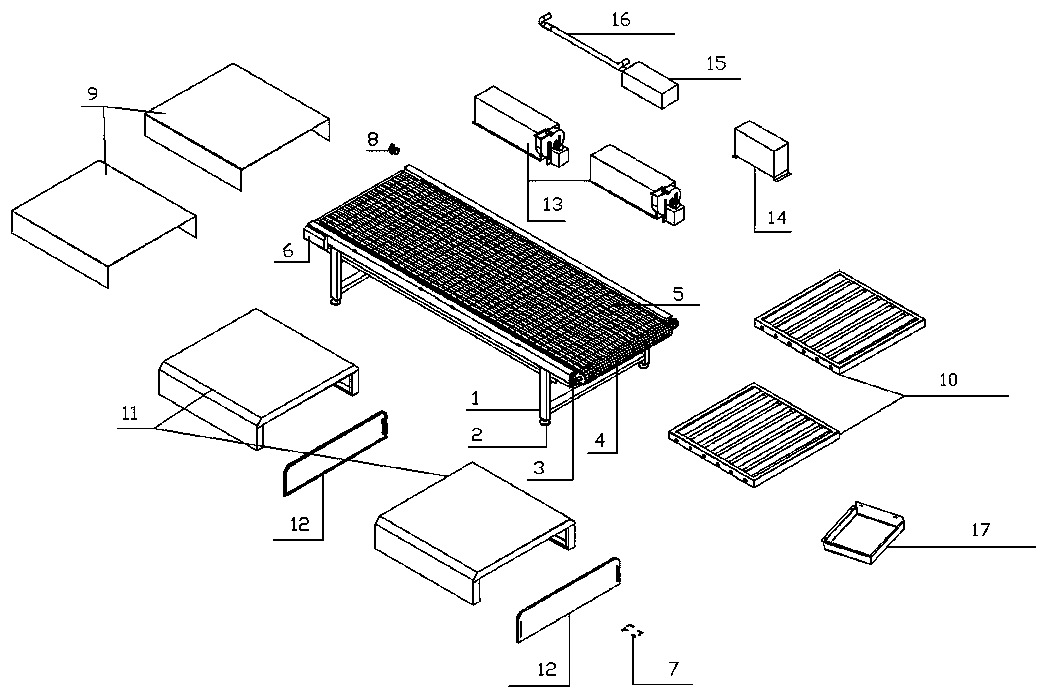

[0021] see Figure 1-3 , a water-based paint heating and dehumidification drying tunnel, including a drying tunnel frame 1, the two ends of the drying tunnel frame 1 are rotatably equipped with circular shafts 4, the two circular shafts 4 are coated with the same stainless steel wire mesh 5, and the drying tunnel frame The upper part of 1 is fixedly connected with a drying channel outer cover 11 in the shape of openings at both ends. The inner part of the drying channel outer cover 11 is inlaid with a drying channel liner 9, and the space between the drying channel outer cover 11 and the drying channel liner 9 is filled with thermal insulation rock wool , the drying channel liner 9 is equipped with a frame, a number of evenly distributed heating pipes 10 are arranged in the frame, and the upper part of the drying channel outer cover 11 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com