Mold for quick injection molding of fan blades

A fan blade and mold technology, which is applied in the field of rapid injection molds, can solve the problems of inconvenient heat dissipation and slow fan blade shaping speed, and achieve the effects of accelerating cooling shaping speed, improving production efficiency, and speeding up shaping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

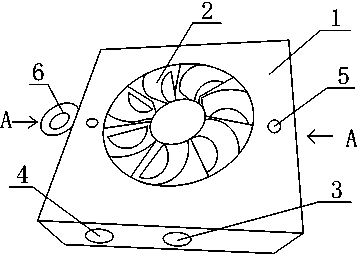

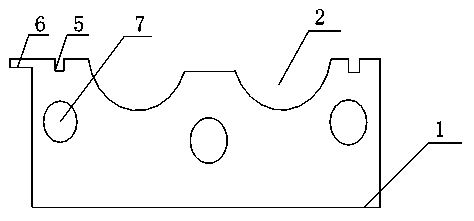

[0022] like figure 1 A mold for rapid injection molding of fan blades is shown, which includes a mold body 1 and an upper mold matched with the mold body 1, the mold body 1 is provided with a fan blade injection groove 2, and the mold A cold water flow pipe 7 is arranged in the body 1, and the cold water flow pipe 7 is located at the bottom of the fan blade injection groove 2, and a pull ring 6 is fixed on the side of the mold body 1.

[0023] The mold body 1 and the upper mold cooperate to shape the upper and lower sides of the fan blades, and cold water is introduced into the cold water flow pipe 7 to accelerate the cooling rate of the thermoplastic parts in the mold body 1 . By operating the pull ring 6, the upper and lower sides of the mold body 1 can be turned upside down, even if the cold water flow pipe is located above the fan blade injection groove 2, the cooling speed of the thermoplastic part can be accelerated by the cold water.

Embodiment 2

[0025] like figure 1 As shown, on the basis of Embodiment 1, the present embodiment is provided with a water inlet 3 and a water outlet 4 on the mold body 1, and the two ends of the cold water flow pipe 7 are connected with the water inlet 3 and the water outlet 4 respectively. connected.

[0026] The water inlet 3 and the water outlet 4 are provided with switches.

[0027] The mold body 1 is provided with an upper mold locking hole 5 .

[0028] The upper mold locking hole 5 is located around the injection groove 2 of the fan blade, and the upper mold locking hole 5 is provided with threads.

[0029] There are at least two locking holes 5 in the upper mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com