An electric turbocharger

A turbocharger and electric technology, applied to combustion engines, engine components, machines/engines, etc., can solve problems such as assembly errors and turbo lag, and achieve the effect of reducing models, reducing quantities, and avoiding assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

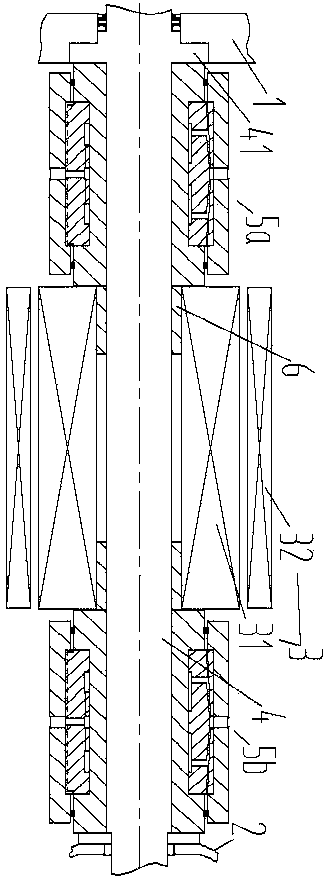

[0034] like Figure 1 to Figure 5 Electric turbochargers shown, including:

[0035] The exhaust gas turbine 1, the compressor 2 and the motor 3 installed on the same shaft 4, the motor 3 is located in the middle of the exhaust gas turbine 1 and the compressor 2, the motor 3 includes a rotor 31 and a stator 32, the stator is fixedly installed on the engine body, The rotor 31 is installed on the shaft 4, and the shaft 4 between the exhaust gas turbine 1 and the motor 3 and the compressor 2 and the motor 3 is installed with a bearing assembly 5a and a bearing assembly 5b;

[0036] The shaft 4 is formed with a shoulder 41 on the side of the exhaust gas turbine 1, and the a shoulder 41 is fitted with the casing 1b of the exhaust gas turbine 1;

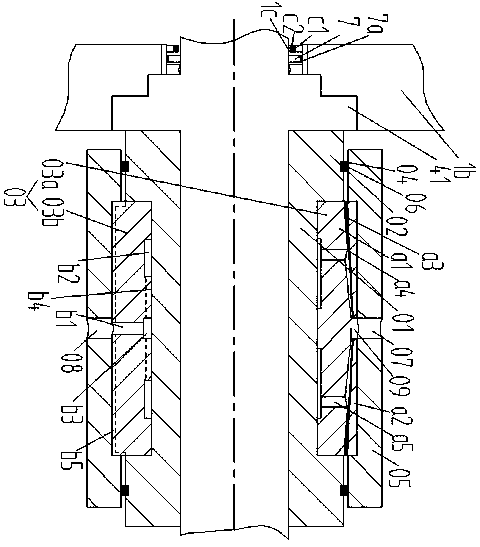

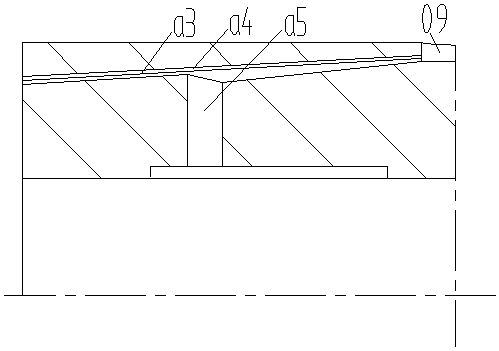

[0037] The bearing assembly 5a, 5b includes a shaft sleeve 01 coaxially sleeved on the shaft, a bearing bush 03 and a bearing shell 05. One end of the shaft sleeve 01 is abutted against and mounted on the side wall of the a shoulder 41, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com