Water-cooled motor casing

A water-cooled motor and motor casing technology, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems that affect the normal heat dissipation of the motor, the motor casing is not tightly fitted, and the water pipe is not firmly fixed. Achieve the effect of ensuring firmness, avoiding position deviation and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

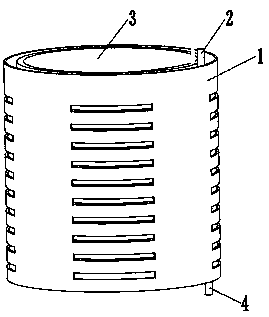

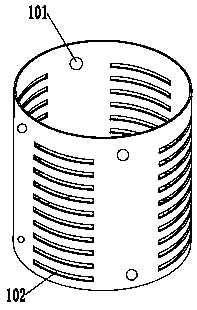

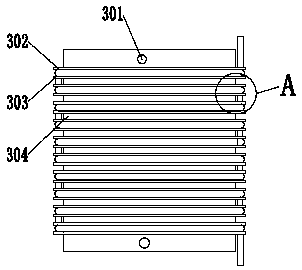

[0027] see Figure 1-5 , a water-cooled motor casing, the outer side of the motor casing is wound with a water pipe for cooling, it is characterized in that: the motor casing includes a water-cooled protective casing 1, an inner casing 3, and the outer side of the inner casing 3 is provided with a multi-layer The guard plate, the water pipe 6 is wound between the guard plates, the upper end of the motor housing is provided with a water inlet pipe 2, and the lower end of the motor housing is provided with a water outlet pipe 4, and the water inlet pipe 2 and the water outlet pipe 4 are evenly connected to the water pipe 6 Connection, the water-cooling shell 1 is arranged on the outside of the inner shell 3, and the water-cooling shell 1 and the inner shell 3 are connected by bolts.

Embodiment 2

[0029] In this embodiment, a water-cooled motor casing, the outer side of the motor casing is wound with a water pipe for cooling, the feature is that: the motor casing includes a water-cooled protective casing 1, an inner casing 3, and the inner casing 3 The outer side is provided with multi-layer guard plates, the water pipe 6 is wound between the guard plates, the upper end of the motor housing is provided with a water inlet pipe 2, and the lower end of the motor housing is provided with a water outlet pipe 4, and the water inlet pipe 2 is connected with the outlet pipe. The water pipe 4 is evenly connected with the water pipe 6, and the water-cooling sheath 1 is arranged on the outside of the inner shell 3, and the water-cooling sheath 1 and the inner shell 3 are connected by bolts.

[0030] In this embodiment, the guard plate is a ring structure, the inner ring of the guard plate is sleeved on the outside of the inner shell 3, and the guard plate and the inner shell 3 are ...

Embodiment 3

[0033] In this embodiment, a water-cooled motor casing, the outer side of the motor casing is wound with a water pipe for cooling, the feature is that: the motor casing includes a water-cooled protective casing 1, an inner casing 3, and the inner casing 3 The outer side is provided with multi-layer guard plates, the water pipe 6 is wound between the guard plates, the upper end of the motor housing is provided with a water inlet pipe 2, and the lower end of the motor housing is provided with a water outlet pipe 4, and the water inlet pipe 2 is connected with the outlet pipe. The water pipe 4 is evenly connected with the water pipe 6, and the water-cooling sheath 1 is arranged on the outside of the inner shell 3, and the water-cooling sheath 1 and the inner shell 3 are connected by bolts.

[0034] In this embodiment, the guard plate is a ring structure, the inner ring of the guard plate is sleeved on the outside of the inner shell 3, and the guard plate and the inner shell 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com