High-speed motor strong air cooling structure

A technology for strong wind cooling and high-speed motors, applied in cooling/ventilation devices, shape/style/structure of winding conductors, electrical components, etc., can solve problems such as poor heat dissipation of high-speed motors, achieve good heat dissipation effects, and prolong the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

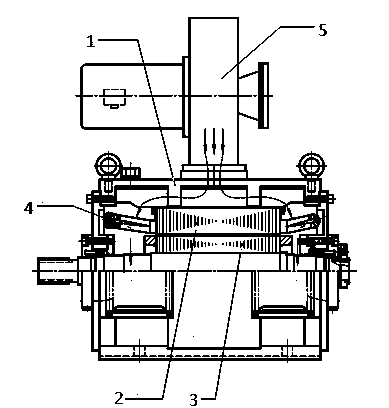

[0011] Such as figure 1 The high-speed motor strong wind cooling structure shown includes a base 1 and a fan 5. The base 1 is provided with a stator 2 and a rotor 3 opposite to the stator 2. Both sides of the stator 2 and the rotor 3 are winding end sides 4. The base 1 is provided with an air inlet, an air duct passing through the end side of the winding and an air outlet connected to the air duct, the fan 5 is connected with the air inlet on the base 1, and a filter for filtering air is provided in the fan 5 , The side of the base 1 is provided with shutters communicating with the air outlet communicating with the air duct.

[0012] The above are only preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, some modifications and improvements can be made without departing from the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com