A method for drying and incinerating dewatered sludge

A technology for dewatering sludge and sludge incineration, which is used in dewatering/drying/concentrating sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., and can solve the problem of increasing carbon dioxide emissions, increasing fuel and air consumption, etc. problems, to achieve the effect of lightening load, reducing fuel consumption, and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

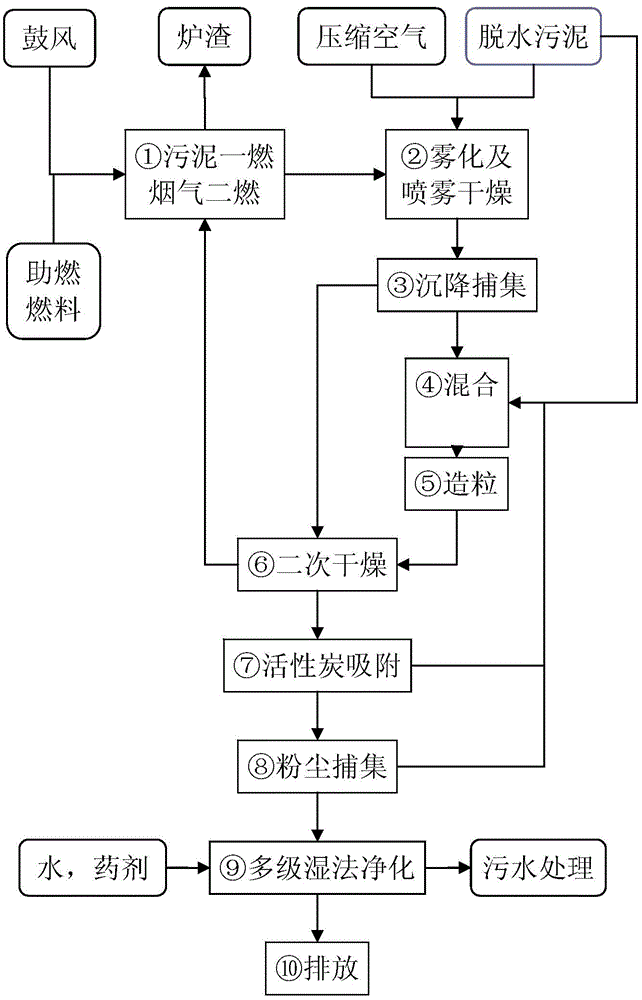

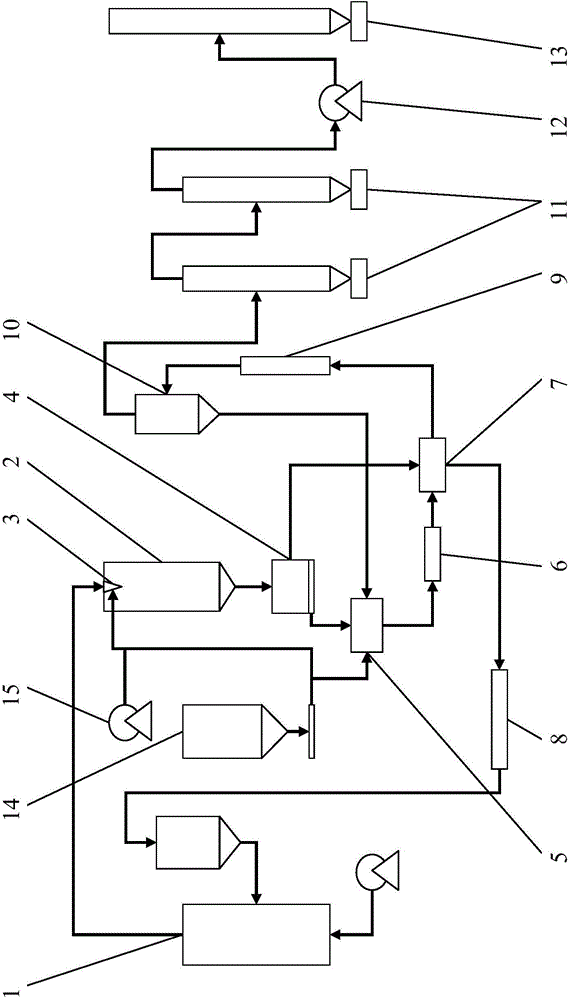

[0067] Embodiment one: if figure 2 It is suitable for drying and incineration treatment of municipal and non-hazardous industrial dewatered sludge.

[0068] The dry sludge incinerator for implementing this method is a fluidized bed incineration hot blast stove 1, including a supporting secondary combustion chamber, dry sludge storage and feeding device, blower, etc.; the sludge spray drying tower 2 for implementing this method is downward Co-current spray drying tower, the top inlet of which is connected to the flue gas outlet of the second combustion chamber on the top of the incinerator through the flue gas pipe; the sludge atomizer 3 implementing this method is an airflow atomizing nozzle, and the dry mud settling chamber 4 is a horizontal type The settling chamber, the secondary dryer 7 is a vibrating fluidized dryer, the activated carbon chamber 9 is an injector for activated carbon powder, the dust collector 10 is a bag filter, and the multi-stage wet spray tower 11 is ...

Embodiment 2

[0080] Example 2: Drying and incineration treatment methods suitable for high oil content dewatered sludge

[0081]The dry sludge incinerator 1 for implementing the method is a horizontal rotary kiln incineration hot blast stove, adopts downstream feeding, and is provided with a flue gas secondary combustion chamber above the air outlet. The incineration hot blast stove includes supporting ignition devices, dry sludge storage and feeding devices, blowers, etc.;

[0082] The spray drying tower 2 for implementing the method is an upward co-current spray drying tower, and its bottom inlet is directly connected with the flue gas outlet at the top of the second combustion chamber of the incinerator 1 . The sludge atomizer 3 that implements this method is an airflow atomization nozzle, the dry mud settling chamber 4 is a horizontal settling chamber, the secondary dryer 7 is a vibrating fluidized dryer, the activated carbon chamber 9 is an activated carbon powder injector, and the du...

Embodiment 3

[0086] Example 3: Mixed drying and incineration treatment methods suitable for dewatered sludge with different moisture content

[0087] The dry sludge incinerator 1 that implements the method is a fluidized bed incineration hot blast stove, including supporting secondary combustion chambers, dry sludge storage and feeding devices, blowers, etc.; the spray drying tower 2 that implements the method is a downward parallel flow Spray drying tower, the top inlet of which is connected to the flue gas outlet of the second combustion chamber on the top of the incinerator through the flue gas pipe; the sludge atomizer 3 for implementing this method is an airflow atomizing nozzle, and the dry mud settling chamber 4 is a horizontal settling chamber , the mixer 5 is a crushing mixer, the secondary dryer 7 is a vibrating fluidized dryer, the activated carbon chamber 9 is an activated carbon powder injector, the dust collector 10 is a bag filter, and the multi-stage wet spray tower 11 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com