Diameter-changeable pulsating heat pipe

A pulsating heat pipe and variable diameter technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as influence and poor overall heat transfer performance, and achieve the effects of overcoming shear stress, shortening start-up time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

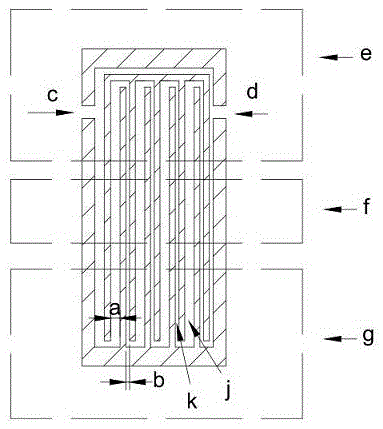

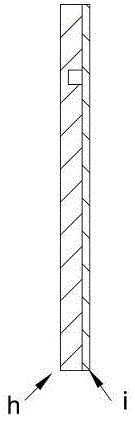

[0016] The variable-diameter pulsating heat pipe of the present invention includes an evaporating section, an adiabatic section and a condensing section, wherein the pulsating heat pipe vacuum port and the pulsating heat pipe processing port are respectively opened at the left and right ends of the condensing section, and the upper and lower bends of the pulsating heat pipe are connected to each other. Adjacent to the main channels of different hydraulic diameters, and connected in a serpentine distribution on the entire silicon plate;

[0017] The cross-sections of the main channels with different hydraulic diameters can be triangular, quadrangular and other shapes.

[0018] The hydraulic diameter of the main channel of the pulsating heat pipe meets the requirements of the following formula: ;

[0019] In the formula, g is the acceleration of gravity, d is the equivalent diameter, ρ is the density of the filling liquid in the pulsating heat pipe, σ is the surface tension, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com