Wind cooling heat radiation structure of power battery pack

A power battery pack and heat dissipation structure technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve problems such as uneven fluid distribution, achieve good temperature uniformity and heat dissipation effects, reduce maintenance costs, and reduce temperature differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

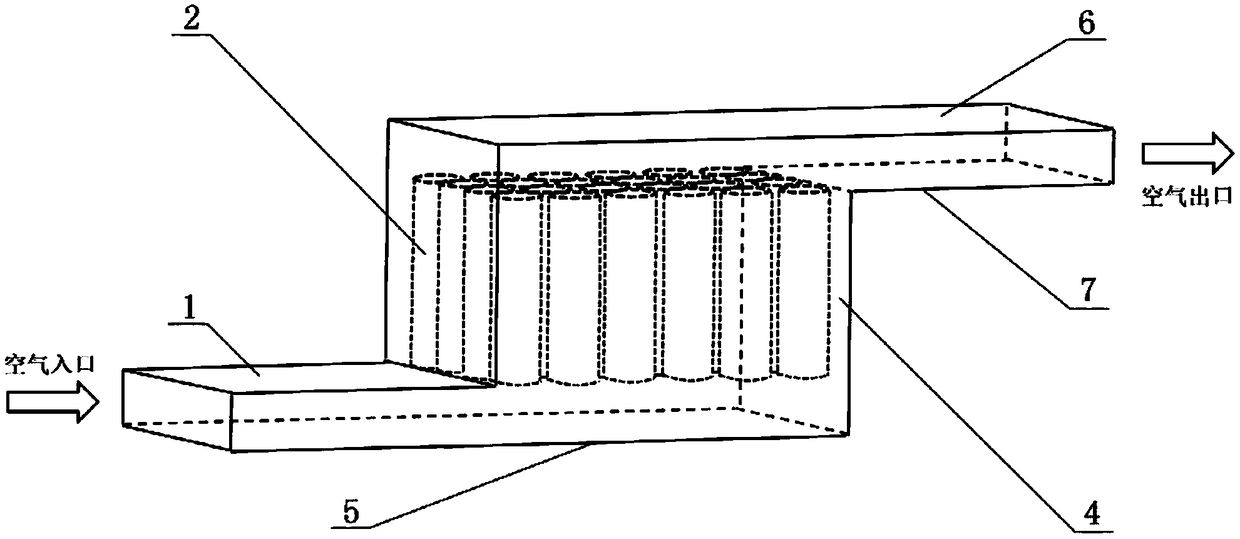

[0048] This embodiment discloses an air-cooled heat dissipation structure for a power battery pack, such as Figure 6 As shown, it includes a box body 4 for accommodating a power battery pack 2 and an air inlet channel 1 and an air outlet channel 7 communicating with the box body 4 , and the overall outer contour is in a Z-shaped structure. The multiple single power batteries of the power battery pack are vertically placed in the box. The air inlet channel 1 and the air outlet channel 7 are respectively arranged on two opposite sides of the box body 4; the bottom surface of the box body is a deflector 5, and the top surface of the box body is a collector plate 6; The deflector 5 is on the same plane as the bottom plate of the air inlet channel 1, and the top plate of the collector plate 6 and the air outlet channel 7 is on the same plane;

[0049] The side of the collector plate 6 close to the box is provided with a shunt 3, that is, the air-cooled heat dissipation structure ...

Embodiment 2

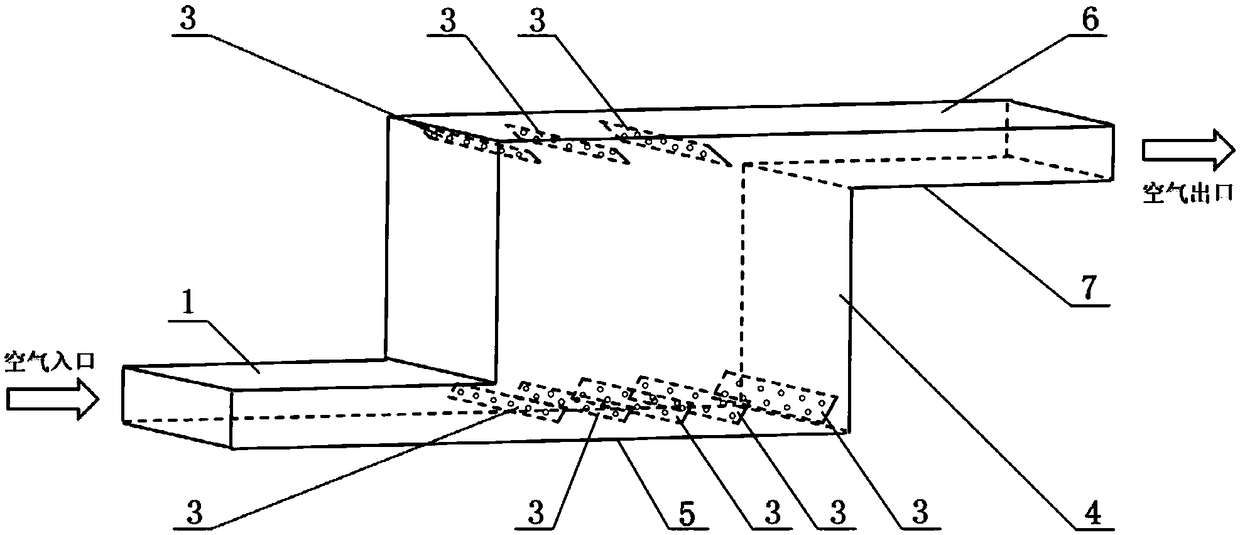

[0053] This embodiment discloses an air-cooled heat dissipation structure for a power battery pack, such as Figure 7 As shown, the air-cooled heat dissipation structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the side of the deflector 5 close to the box is provided with a shunt 3, that is, only the lower side of the battery box is provided with a shunt , the splitters are five pieces, the angle of inclination of the five splitters is 60°, the lengths are 4mm, 6mm, 8mm, 10mm, 12mm, and they are evenly distributed on the lower side of the box at equal intervals.

[0054] When the air fluid enters the air inlet channel 1, it first passes through the interference of the first splitter 3 on the lower side, and then part of the fluid is distributed among the cells close to the air inlet channel 1, and the rest of the air fluid passes through the upper and lower sides of the splitter. The side continues to flow backward, and when it e...

Embodiment 3

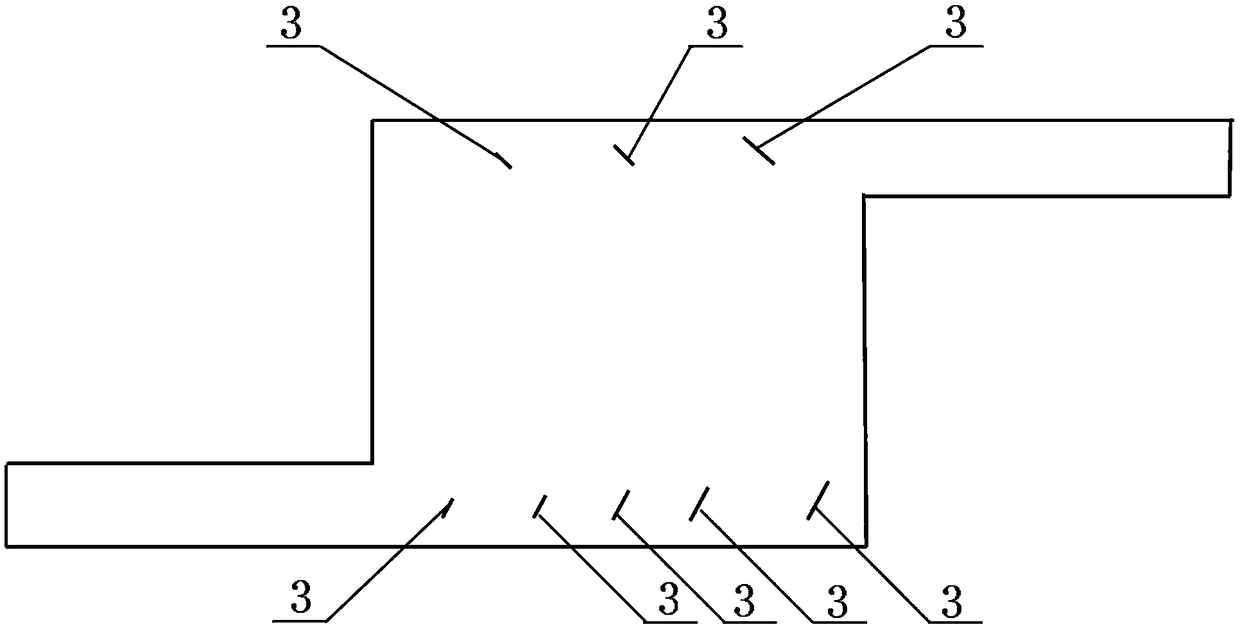

[0057] This embodiment discloses an air-cooled heat dissipation structure for a power battery pack, such as Figure 8 As shown, the air-cooled heat dissipation structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the side of the collector plate 6 and the deflector 5 close to the box is provided with a shunt 3, that is, the battery box Both upper and lower sides are provided with shunt pieces, with 3 pieces on the upper side and 5 pieces on the lower side.

[0058] When the air fluid enters the air inlet flow channel 1, after passing through the interference of the first splitter on the lower side, part of the fluid is distributed between the single cells close to the inlet flow channel, and the rest of the air fluid continues to flow through the upper and lower sides of the splitter. After the flow, when it encounters the second splitter, it continues to separate part of the fluid to flow between the upper flow channels, and so on....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com