Panel structure of electromagnetic heating device

A technology for heating appliances and panels, applied in electric heating fuel, lighting and heating equipment, household heating, etc., can solve the problem of temperature control of the upper pot without considering the thermal influence of the curved ceramic panel, panel heat dissipation, induction cooker long work issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

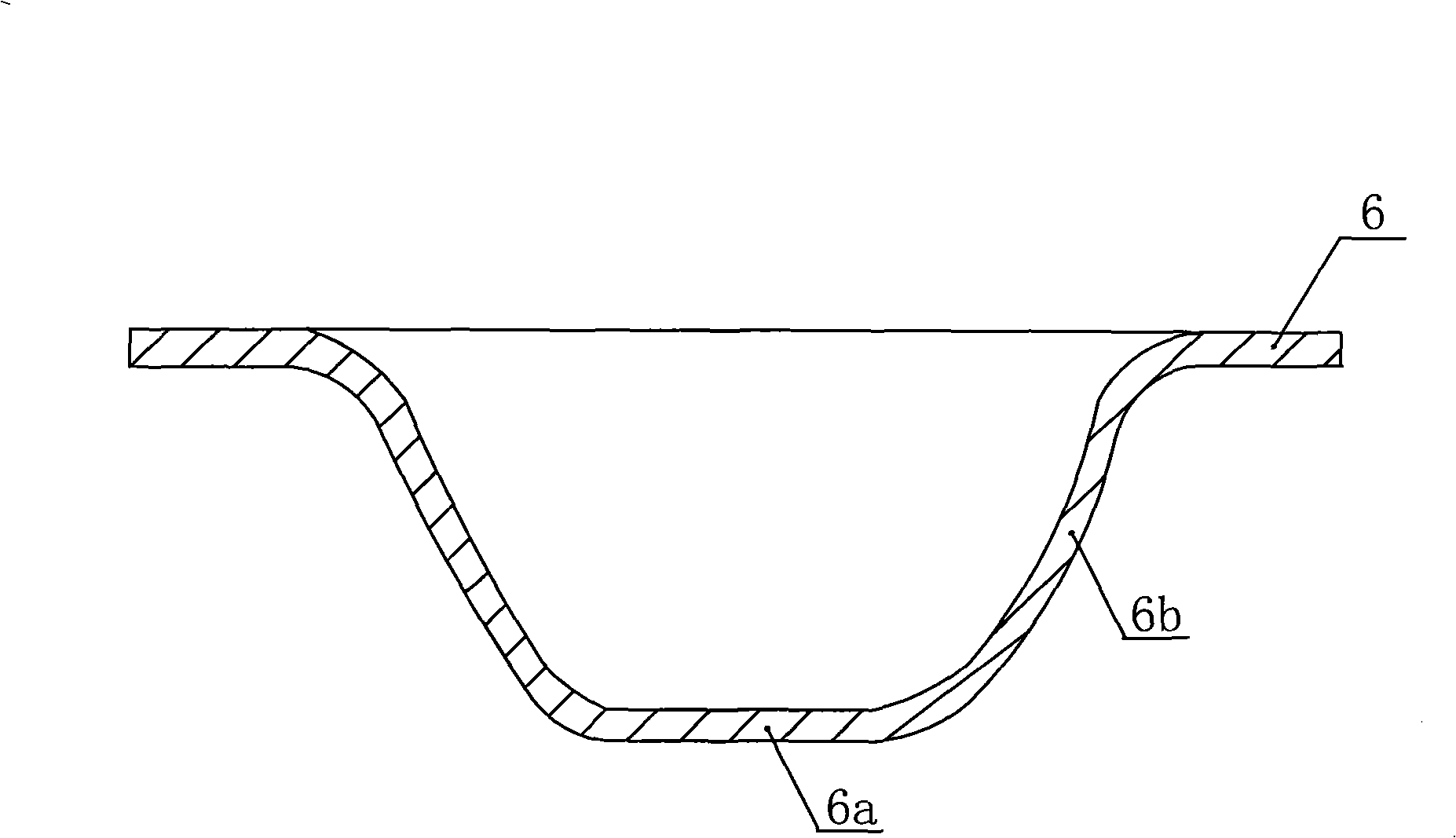

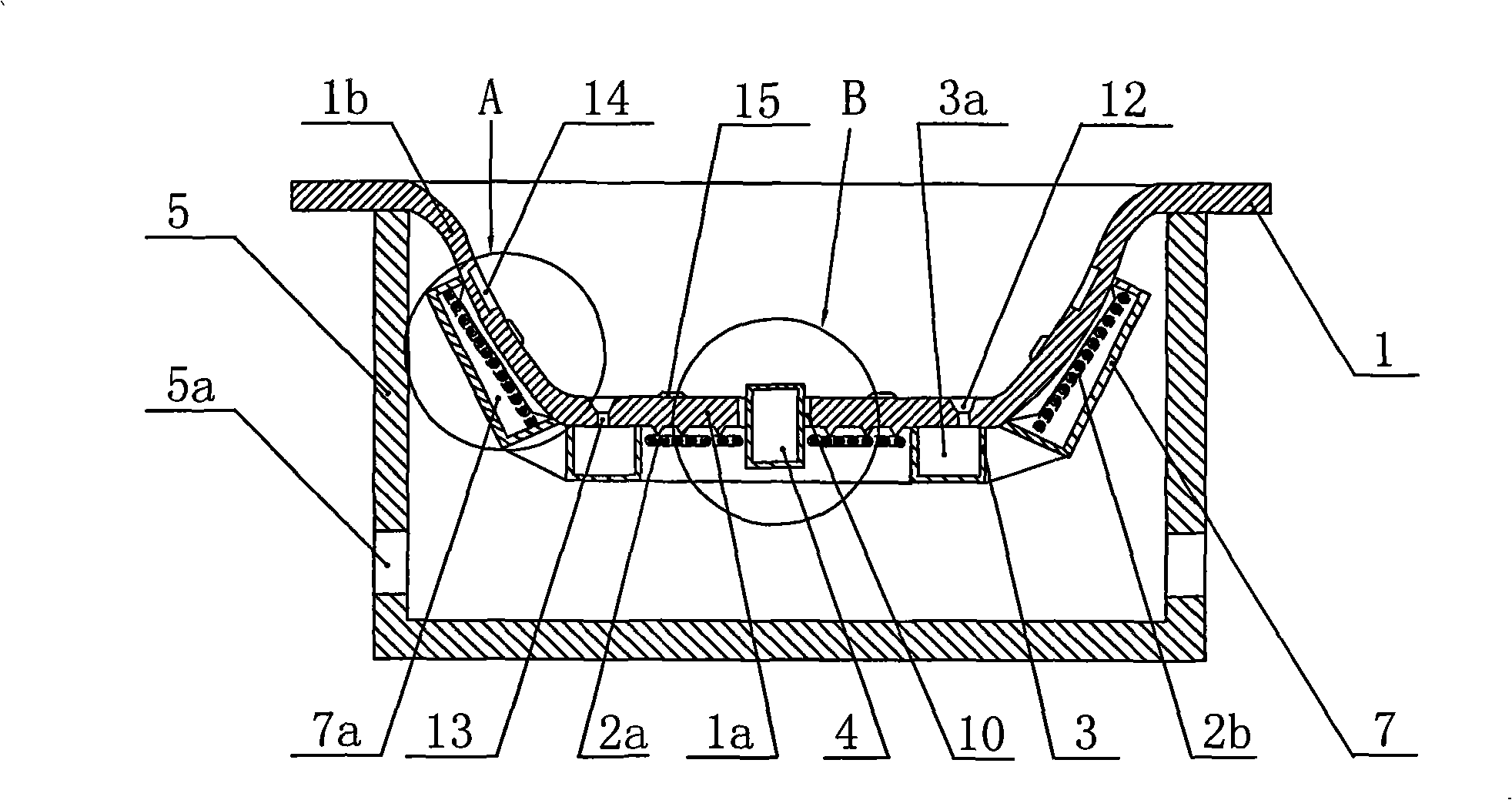

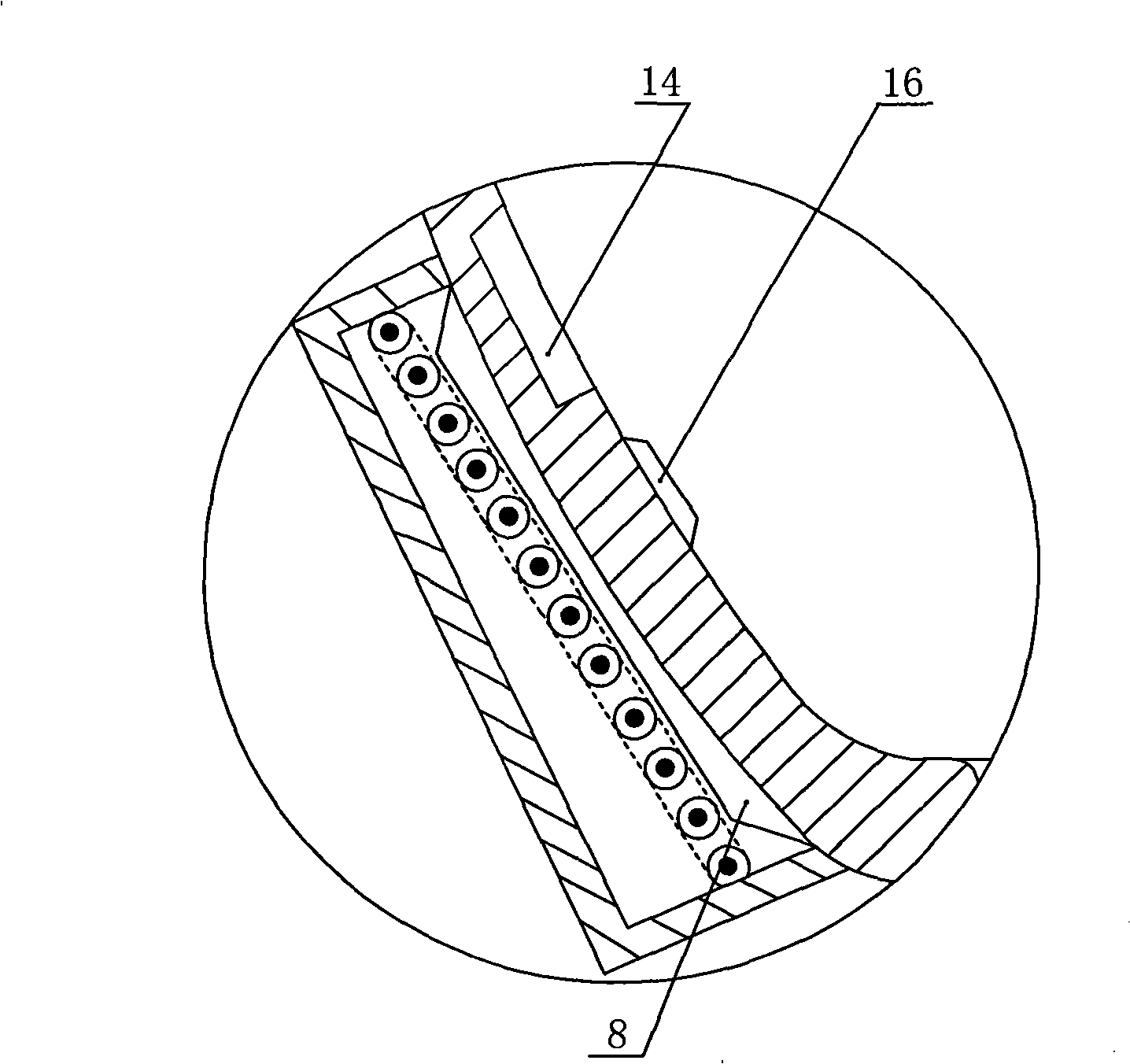

[0048] Such as figure 1 , figure 2 As shown, a new type of electromagnetic heating appliance includes a panel 1 and a housing 5 supporting the panel 1, wherein the panel 1 is made of temperature-resistant and magnetically permeable plastic. Parts such as control system and fan are accommodated in the housing 5; the side wall of the housing 5 is provided with an air inlet 5a, and a forced air fan (not shown in the figure) can also be set at the air inlet 5a position. out). The panel 1 has a concave arc shape, and the panel 1 includes a substantially flat bottom wall 1a and a side wall 1b surrounding the bottom wall 1a to form a concave arc panel, wherein the bottom wall 1a Constitute the bottom area of the panel 1; a temperature sensor installation hole 10 is provided at the center of the bottom wall 1a, and a temperature sensor 4 that can be electrically connected to the control system of the electromagnetic heating appliance is arranged in the temperature sensor installa...

Embodiment 2

[0061] Such as Figure 7 , Figure 8 As shown, the difference from Embodiment 1 is that the panel 1 is in a concave arc shape, and the panel 1 includes a bottom wall portion 1a which is basically a small concave arc shape and a concave arc-shaped panel formed around the bottom wall portion 1a The side wall portion 1b; wherein the small concave arc-shaped bottom wall portion 1a is in a gradually (gradually) concave shape downward, and the center position of the bottom wall portion 1a is basically at the lowest point of the bottom wall portion 1a Point, the concave arc diameter R1 of the bottom wall portion 1a is larger than the concave arc diameter R2 of the side wall portion 1b.

[0062] Such as Figure 9 As shown, as an equivalent implementation structure of the bottom wall portion 1a, wherein the small concave arc-shaped bottom wall portion 1a is in a gradually (gradually) convex shape, and the center position of the bottom wall portion 1a It is basically at the highest p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com