Turbine blade with three-dimensional mesh woven fibers

A turbine blade and braided fiber technology, which is applied in the cooling field of gas turbine blades to achieve the effects of improving thermal conductivity, improving temperature distribution uniformity, and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

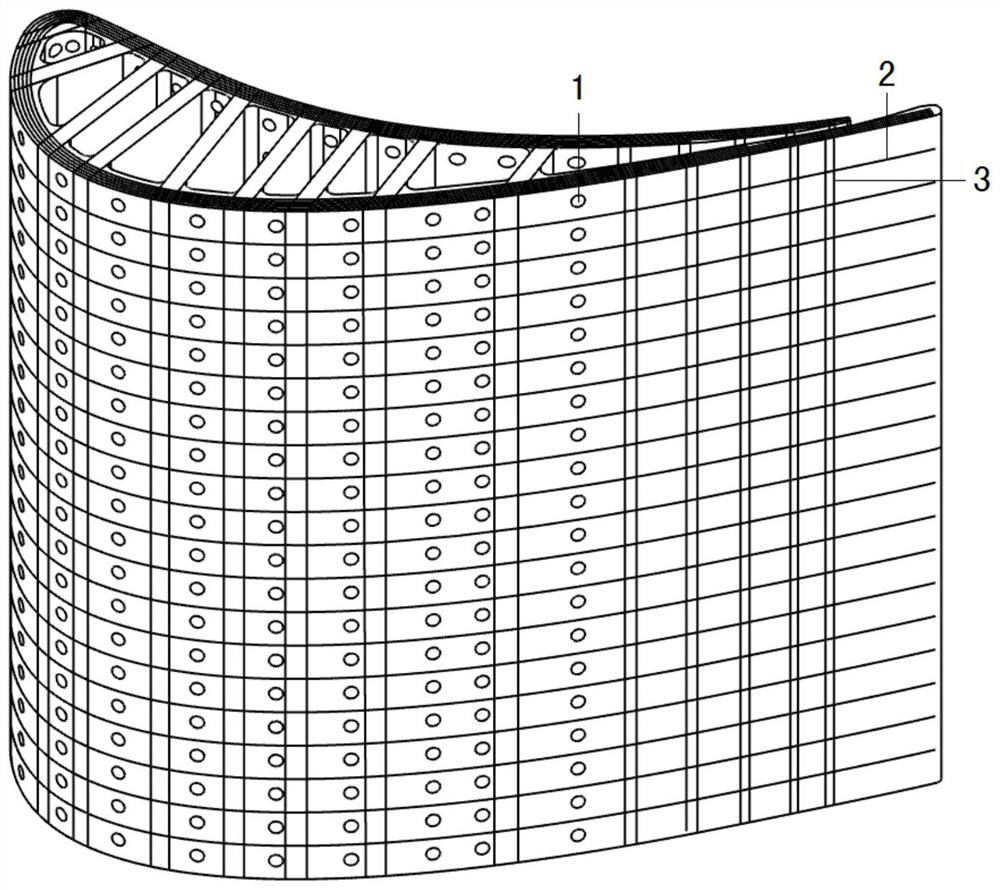

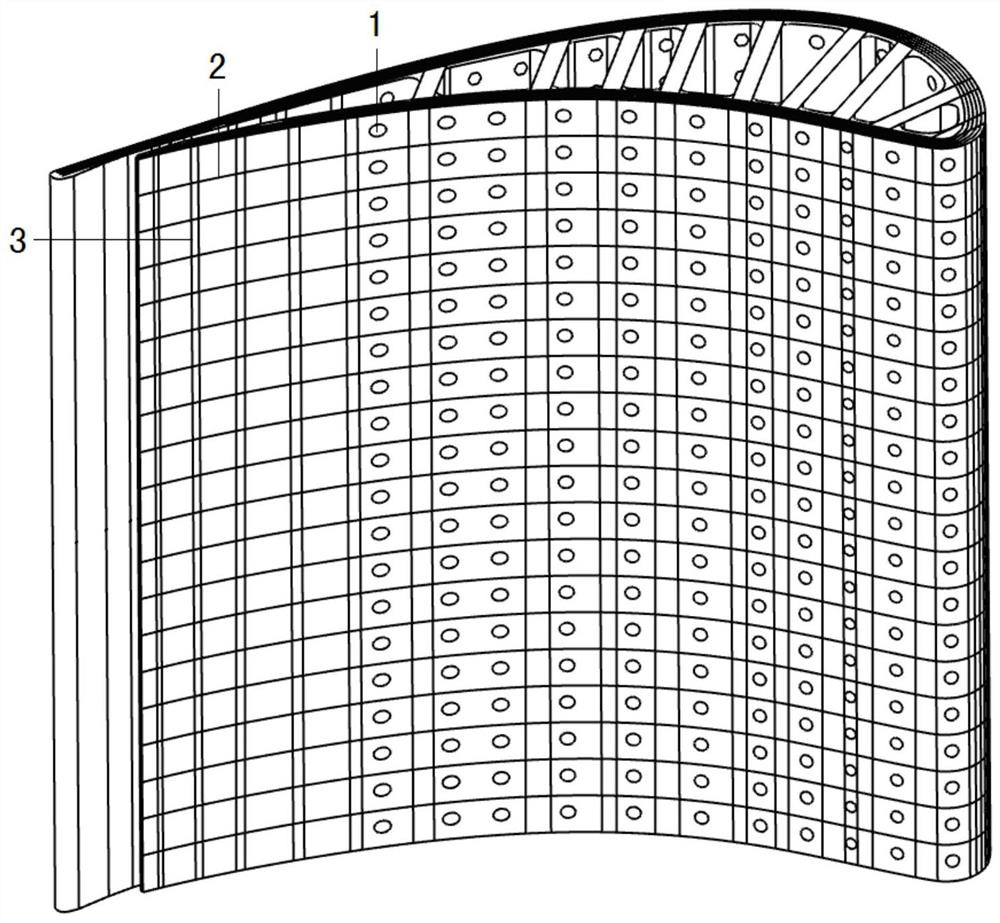

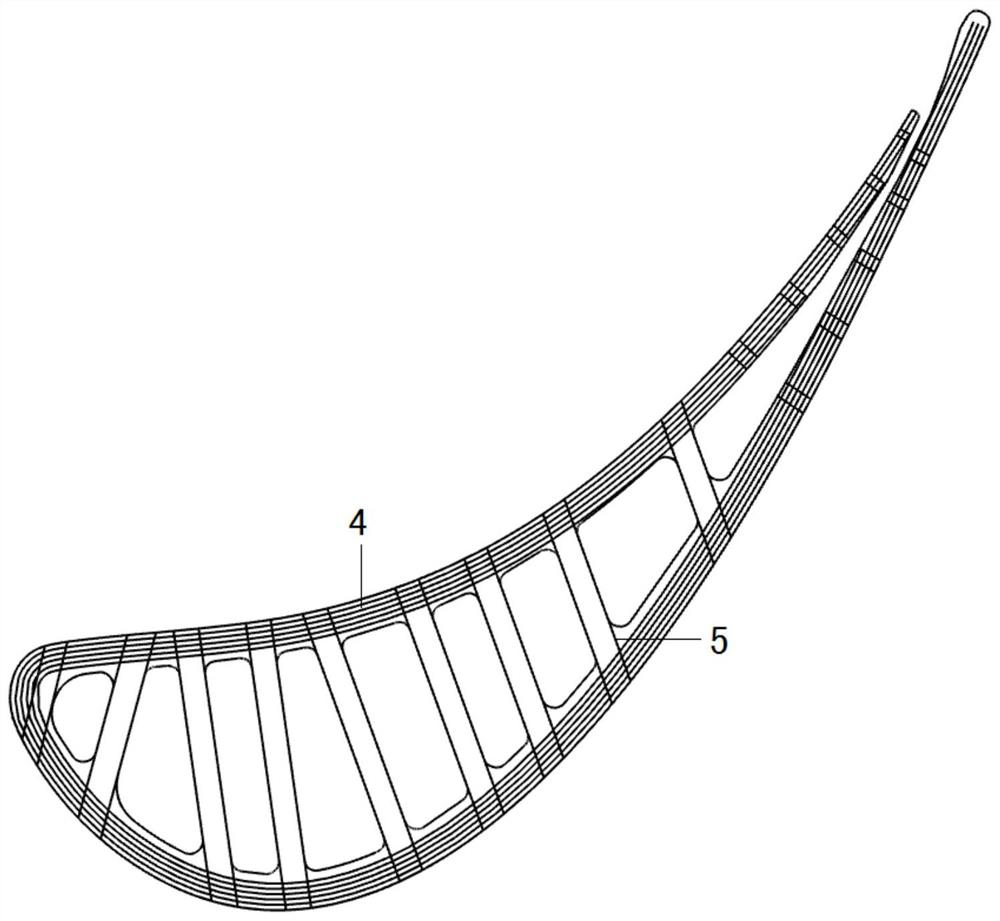

[0022] Such as Figure 1~4 As shown, a turbine blade with added three-dimensional net-like braided fibers is attached with three-dimensional net-like braided fibers on the wall surface and inside of the turbine blade, and the diameter of the fibers is 0.1 mm to 0.15 mm.

[0023] On the suction surface of the turbine blade and the wall surface of the pressure surface, the fibers surround the gas mold hole 1 and are distributed around the gas mold hole 1, where the fibers include wall transverse fibers 2 and wall vertical fibers 3; the wall transverse direction The fibers 2 are distributed at equal intervals along the blade height direction, and the spacing is 2 mm; the vertical fibers 3 on the wall are distributed at variable intervals along the direction of the blade shape, and the spacing ranges from 0.44 mm to 5.4 mm.

[0024] On t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com