Rapid heat-treatment temperature measuring and controlling system and measuring and controlling method

A technology for rapid heat treatment and temperature measurement, applied in temperature control, control/regulation systems, non-electric variable control, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

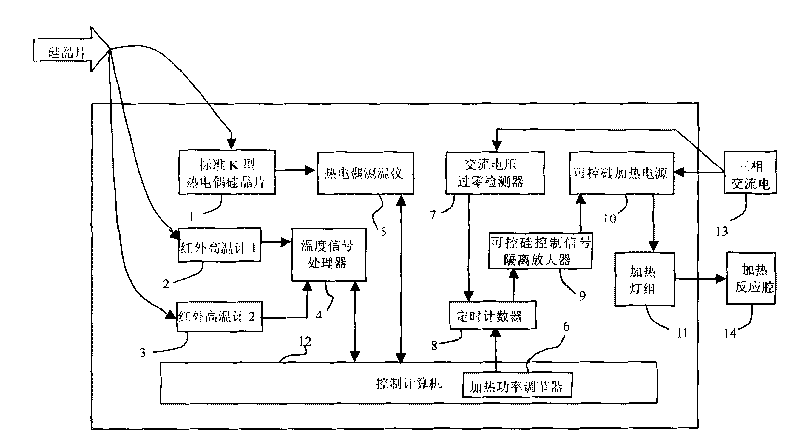

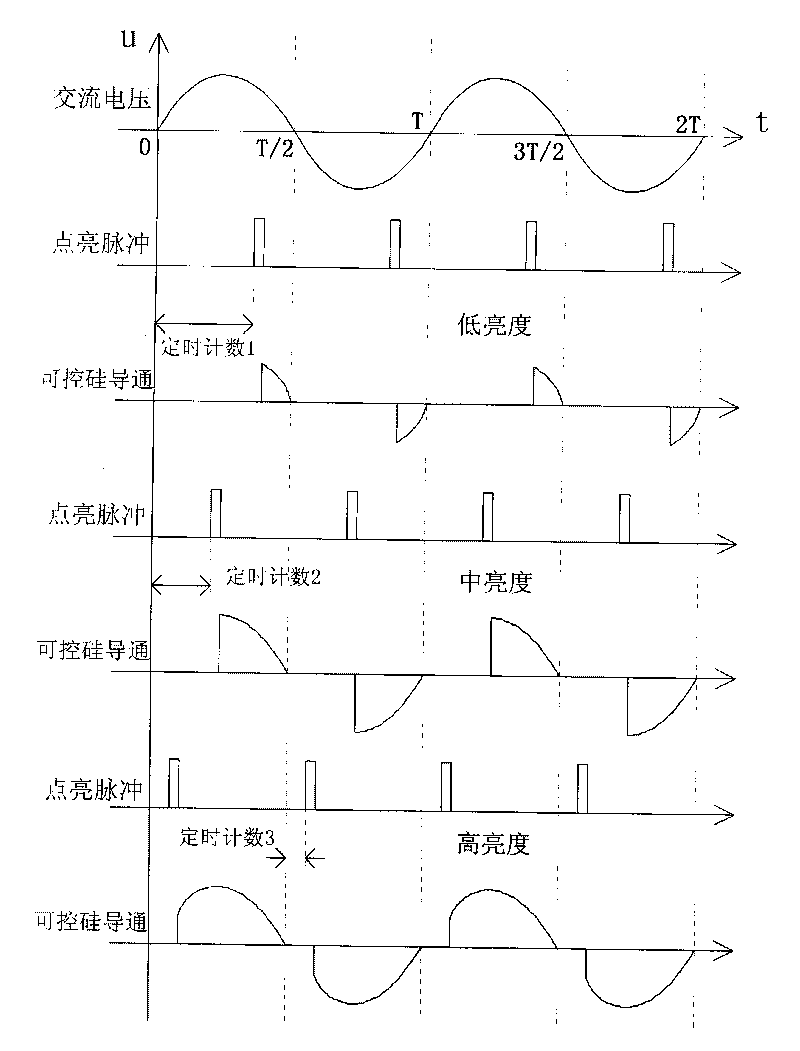

Method used

Image

Examples

Embodiment

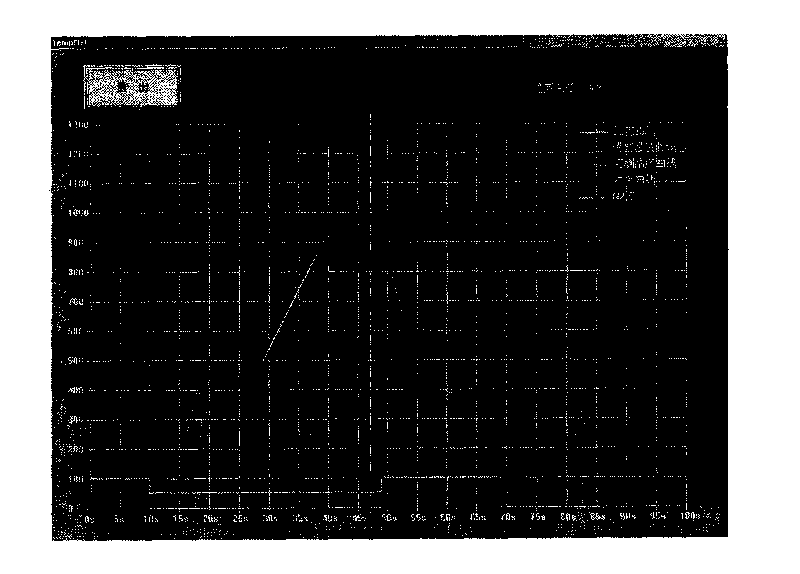

[0088] Record a set of rapid heat treatment process data according to the above method as follows:

[0089] Process silicon wafer size: 8 inches. An 8-inch silicon wafer was used for rapid heat treatment annealing test, and the 8-inch silicon wafer was first implanted with B by an ion implanter. + Ions, the implantation energy of the ion implanter is set to 150kev, and the implantation dose is set to 1×10 14 ion / cm 2 . The implanted silicon wafers are sent to a rapid annealing furnace for rapid thermal annealing, and the high temperatures in the stable annealing period are set to 800, 900, 1000, and 1100°C, respectively. The annealed silicon wafer is tested for resistance uniformity with a four-probe square resistance tester, and the resistance uniformity is better than ±0.95%, and the best reaches ±0.76% (3σ).

[0090] image 3 For the real-time process curve diagram of the rapid heat treatment process, the yellow is the edited temperature control process curve, the purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com